rich experienced different kinds of cooler mould

| Model: | 4 |

|---|---|

| Brand: | JY-MO |

| Origin: | Made In China |

| Category: | Home Supplies / Other Home Supplies |

| Label: | cooler mould , water cooler mould , evaporative cooler m |

| Price: |

US $20000

/ pc

|

| Min. Order: | 1 pc |

Product Description

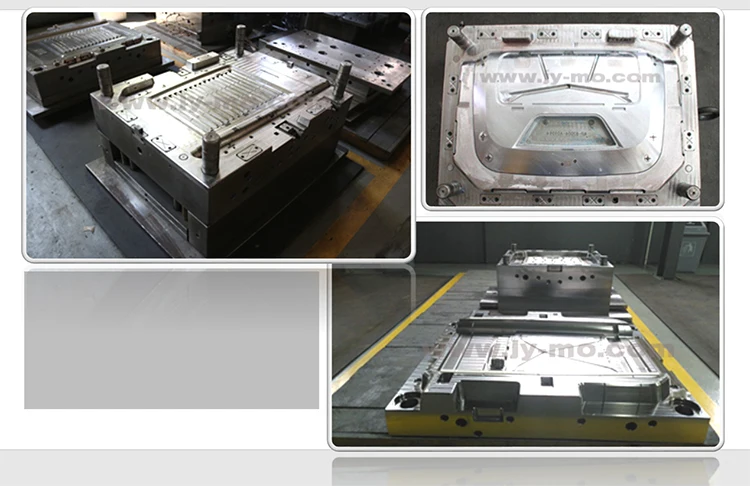

Plastic Air Cooler Mould

Mould specification:

|

Product Name |

Plastic air cooler mould |

|

Product material |

PP,PC,HDPE,PA, ABS, PVC,POM,PMMA etc |

|

Core&Cavity Steel |

P20,718,H13,2316,or as customer's requirement |

|

Steel hardness: |

28-32 HRC, 30-34 HRC |

|

Mold Standard |

LKM,HASCO,DME (option) |

|

Cavity Number |

Single/ Multi |

|

Ejector System |

Stripper plate/ejector pins |

|

Cycle Time |

Short |

|

Tooling lead time |

40-60 days |

|

Mold life |

500,000 -1,00,000 shots |

Our service for u :

We can make all kinds of plastic appliance mould,injection mould according customer drawings or samples,

We could offer product and mold design ,prototypes,moulds according customer inquire,

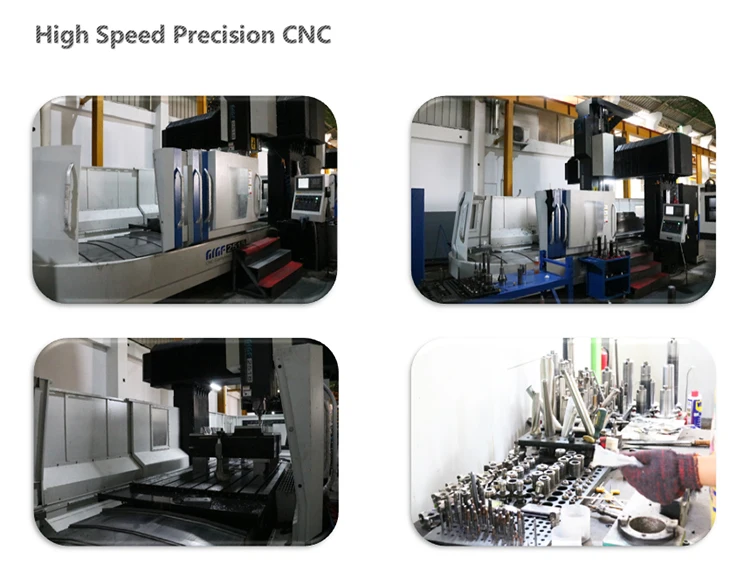

We have a professional technical team and mangerment,advanced equipment ,provide 2D,3D drawings

Our target to save y time and money with high quality mould

We can ensure customer:

1. We can provide you stable quality, faster delivery and clear communications.

2. Our project manager can speak very good English.

3. We devote to be your one-stop solution shop.

4. We can handle different size and type products.

5. We have a very good attitude before our clients, we stay on our promises every moment.

6. Our engineers can help you save money.

7. We can provide steel and hardness certificate to clients, we have very good quality system.

8. We have injection machines from 35 tons to 1800 tons.

9. We have high-speed CNC machine centers.

10. We can offer 2D/3D mould design and mould flow analysis.

Step

|

1. Received inquiry |

By email, Online Talking, or telephone call. |

|

2. Quote within 24 hours |

Send you quotation sheet with all details information |

|

2. Negotiation |

About quality, price, delivery time, payment, shipment ect. |

|

3. Place an order |

According to customer’s requirement to make mould. |

|

4. Drawing |

Customer confirm the final drawing. |

|

5. Mould |

Prepareing steel, shaping, Surface grinder, dowel pin drilling, datum axis, CNC, Milling, Wire Cutting, EDM, Benching, Polishing |

|

6. Sample 1st Trial |

If the 1st sample is not satisfied cusmter, we modify the mould until meet customer’s satisfactory. |

|

7. Confirm the final Sample |

Check and approve the sample. |

|

8. Delivery |

By Sea or by Air. According to customer’s requests. |

FAQ

Q:Does your company make mould by yourself?

A: Yes,we are manufacture with about decade yeas of moulding experience.

Q: How many kinds moulds can you make? Only make the moulds?

A: we can make many kinds of moulds,such as plastic injection moulds,stamping moulds,die casting moulds.Besides, we also can produce the final parts for you.

Q: What is the software you will use to check the drawing?And what is format of drawing you can check?

A: Our designers and engineers all use VISI and UG to check 2D and 3D drawings.

We can check the drawing with PDF .AI, DWG ,STP or IGS formats.

Q: What is your terms of payment ?

A: 30% T/T in advance ,balance before shippment.

Q:How to pack the moulds and products.

A:For moulds,we will be coated one-layer anti-rust oil first,and then then also will be covered thin films on the mould,finally pack into non-fumigation wooden case.And as to products,we will pack into standard export cartons or as per customers request to pack.

| Payment Terms: | TT |

|---|---|

Member Information

| JY-MO Engineering Co.,Ltd. | |

|---|---|

| Country/Region: | Zhe Jiang - China |

| Business Nature: | Manufacturer |

| Phone: | 13738558266 |

| Contact: | Cristina (salesmanager) |

| Last Online: | 13 Nov, 2017 |

Related Products of this Company

-

ventilation plastic home air cooler

US $20000