| Model: | - |

|---|---|

| Brand: | SL |

| Origin: | Made In China |

| Category: | Construction & Decoration / Heat Insulation |

| Label: | Aerogel , Aerogel For New Ener |

| Price: |

¥165

/ pc

|

| Min. Order: | 10 pc |

Product Description

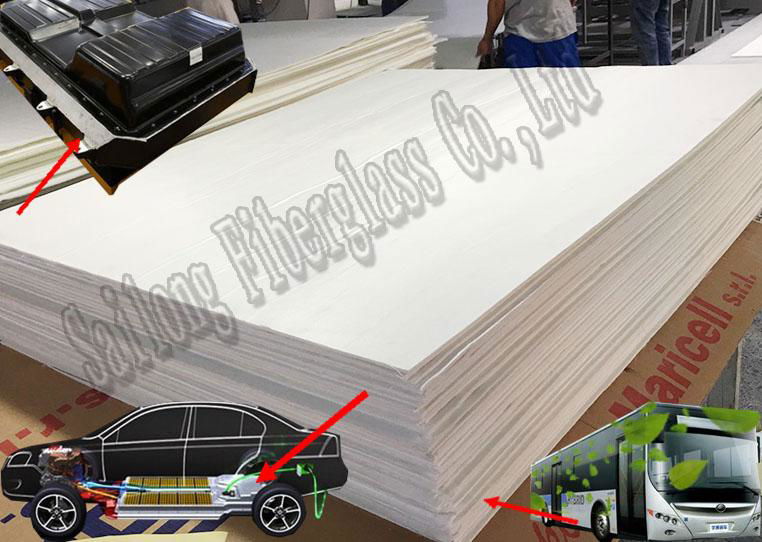

Aerogel For New Energy Automobile:

With the continuous improvement of the performance of the EMU, the structure and material of the car body also has a series of changes, these changes will have a certain impact on the thermal insulation performance of emu. The insulation performance of EMU roof is one of the main factors affecting the heat transfer, to study the effect of different roof structure on thermal insulation performance, for the analysis of the EMU Operation and energy consumption, determine the air conditioning load, avoid adverse conditions (high local temperature, condensation inside) appear, to the car and maintain a comfortable thermal environment has important significance.

With the development of electric vehicles, effects of low temperature in winter on the electric vehicle battery has become very hot, there are more and more discussions about the mileage of electric vehicles the effects of cold temperature, although they can use some tricks to reduce as much as possible because the temperature caused by the consumption of power, but to completely solve this problem, in addition to the use of super thermal insulation material, the current situation, even if the electric car industry leader has no solution.

In general, there are two factors that can lead to a decline in the number of electric vehicle batteries in winter. One is due to the cold air, the other is to turn on the heater when driving in winter. If the temperature is below zero degrees Celsius, the mileage of electric vehicles will be reduced by 30%. Currently used insulation methods are mainly the following two:

The first method used China words is "demolition of the east wall buxiqiang", because the low temperature impact on the electric vehicle is accelerating in the largest power consumption and two aspects to increase the charging time, so the heater method to battery heating, but the heater is driven by electric power, and there is no practical significance too much. In fact, heating the battery by using a heater is also one of the most important factors leading to lower mileage.

Another way is to use the motor to generate heat in the car to heat the battery. Although the two can improve the battery efficiency to a certain extent, but this "heat" is limited, so we must first make electric cars driving a few minutes, then let the car battery temperature reached the normal level, this method is only useful.

The gasoline engine is not a problem because the efficiency of gasoline engines is not high, a large part of the energy generated by the combustion of gasoline is converted into heat energy, the heat will increase the temperature of railway carriage. However, the efficiency of motor vehicles is relatively high, so the excess heat generated is limited.

In addition, if the temperature of the battery is too low, it will affect the performance of regenerative braking system, regenerative braking system is the use of braking power to charge the battery to improve mileage. However, if the regenerative braking system is too much input to the car battery, it will damage the battery at low temperature.

Technically speaking, it is possible to improve the battery performance by reducing the volume of the electrode material composition, which is equivalent to shortening the movement distance of lithium ion. But the smaller the composition, the higher the chemical activity, the lower the safety of the battery, so some additional measures are needed to ensure the safety of the battery. In order to save more energy, the U.S. Department of energy also provides funding for research and development of heat storage material, the heat storage material can be heated in the electric vehicle charging, and the heat released when the car is running, but this kind of thermal storage materials are not used in commercial. In the current situation, the best solution is to improve the insulation of electric vehicles, the use of aerogel super thermal insulation materials to carry out thermal insulation, in order to prevent heat leakage inside the car.

The specifications of nanoporous aerogel insulation of Sailong:

|

item |

unit |

value |

|

Test method |

|

thickness |

mm |

3/6/8/10(±0.5) |

|

---- |

|

color |

--- |

White |

|

visualization |

|

thermal conductivity |

W/(m.k) |

25℃ |

0.014 |

GB/T 10294-2008 |

|

70℃ |

0.018 |

|||

|

300℃ |

0.033 |

|||

|

500℃ |

0.057 |

|||

|

linear shrinkage |

% |

<1.0% |

ASTM-C177 |

|

|

compressive strength |

Kpa |

@10% |

60 |

GB/T13480 |

|

@20% |

120 |

|||

|

compressive strength |

Mpa |

2.0 |

GB/T17911 |

|

|

voidage |

% |

95~98 |

|

|

|

hydrophobic ratio |

% |

99 |

|

GB/T10299-2011 |

|

density |

g/c m³ |

0.18 |

|

GB/T5480-2008 |

|

temperature tolerance |

℃ |

650/1100 |

|

GB/T17430-1998 |

|

burning behavior class |

A |

A |

|

GB8624-2012 |

Member Information

| Shengzhen Sailong Fiberglass Co.,Ltd | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 0755-84294626 |

| Contact: | Mr. Luo (Manager) |

| Last Online: | 23 Dec, 2024 |

Related Products of this Company

-

Power Refractory fiber Mat

-

Glass wool black decorative

-

Specialized Fiberglass Mat For Aerogels

-

Fiberglass Tape

-

Aluminum Foil Aerogel Fiberglass Blanket

-

Aluminum foil tape

-

Flameproof Fabric / Fire-retardant

-

Heat shielding mat for Home Electric

-

Fiberglass heat retention pipe

-

Silica Coated Fiberglass Cloth