| Model: | PC resin |

|---|---|

| Brand: | Fukuang |

| Origin: | Made In China |

| Category: | Chemicals / Plastic Materials |

| Label: | pc resin , PC diffusion , plastic moldingg |

| Price: |

US $2

/ kg

|

| Min. Order: | 25 kg |

Product Description

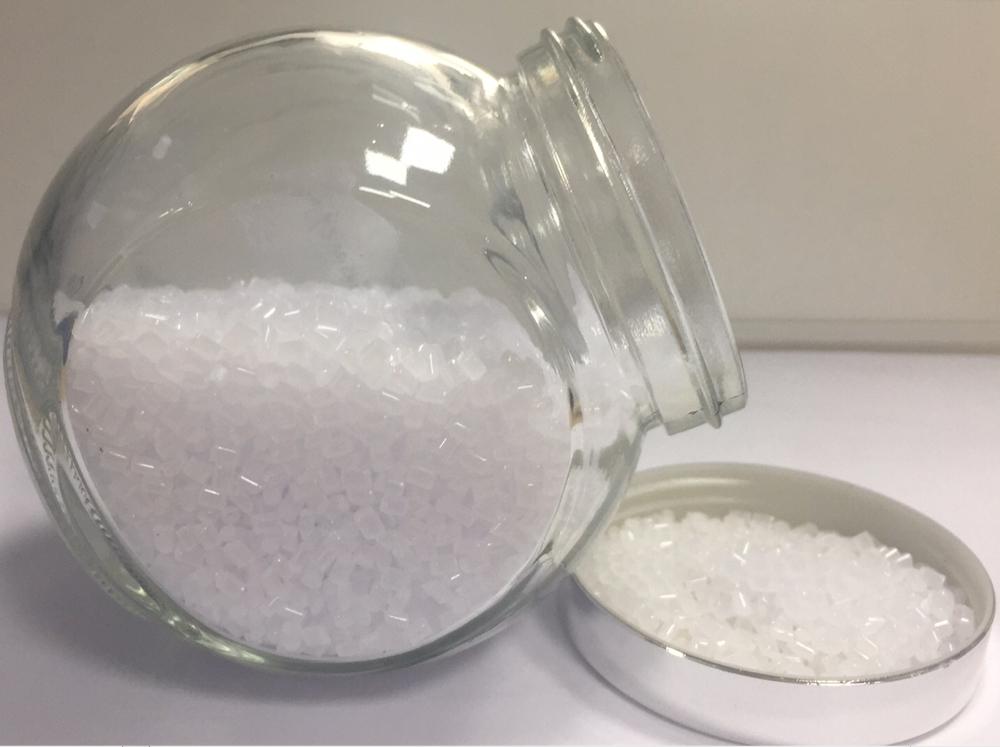

Global grade LUX2110T is an injection moulding grade especially designed for manufacturing optical parts requiring easy flow properties combined with very high transmission and color stability. Widely supplied for electrical and electrical industry.

This is a PC Modified plastic with Light Diffusion effect. These effects have been developed to meet increasing Aesthetic demands in the Marketplace. Color Package may affect properties.

We use high-quality general PC transparent resin to add special additives for modified granulation. All of the modified PC are milky white, outwardly you can’t know the specific properties and the actual effects of this material. Just to through injection molded it into plastic light shell, and then through the internal light bulb or LED light shines, so that light can be very soft and to evenly spread to every place indoors, that can offer people a very comfortable visual experience. According to the color of the internal bulb and LED lights, the PC shell can show a variety of color light scattering effect, that is very beautiful. And also that can avoid the light irritate the eye caused by strong light stimulation and protect the eyes from light exposure damage

| Physical Properties | Metric | English | Comments |

| Specific Gravity | 1.20 g/cc | 1.20 g/cc | ASTM D 792 |

| Density | 1.20 g/cc | 0.0434 lb/in³ | ASTM D 792 |

| Linear Mold Shrinkage, Flow | 0.0060 - 0.0090 cm/cm | 0.0060 - 0.0090 in/in | on Tensile Bar; SABIC Method |

| Melt Flow | 19 g/10 min | 19 g/10 min | ASTM D 1238 |

| @Load 1.20 kg, | @Load 2.65 lb, | ||

| Temperature 300 °C | Temperature 572 °F | ||

| Mechanical Properties | Metric | English | Comments |

| Tensile Strength at Break | 68.0 MPa | 9860 psi | Type I, 50 mm/min; ASTM D 638 |

| Tensile Strength, Yield | 60.0 MPa | 8700 psi | Type I, 50 mm/min; ASTM D 638 |

| Elongation at Break | 143% | 143% | Type I, 50 mm/min; ASTM D 638 |

| Elongation at Yield | 7.00% | 7.00% | Type I, 50 mm/min; ASTM D 638 |

| Tensile Modulus | 2.22 GPa | 322 ksi | 50 mm/min; ASTM D 638 |

| Flexural Yield Strength | 96.0 MPa | 13900 psi | 1.3 mm/min, 50 mm span; ASTM D 790 |

| Flexural Modulus | 2.36 GPa | 342 ksi | 1.3 mm/min, 50 mm span; ASTM D 790 |

| Izod Impact, Notched | 1.43 J/cm | 2.68 ft-lb/in | ASTM D 256 |

| @Temperature -30.0 °C | @Temperature -22.0 °F | ||

| 7.85 J/cm | 14.7 ft-lb/in | ASTM D 256 | |

| @Temperature 23.0 °C | @Temperature 73.4 °F | ||

| Izod Impact, Unnotched | 21.4 J/cm | 40.1 ft-lb/in | ASTM D 4812 |

| @Temperature 23.0 °C | @Temperature 73.4 °F | ||

| Instrumented Impact Energy at Peak | 72.0 J | 53.1 ft-lb | ASTM D 3763 |

| @Temperature 23.0 °C | @Temperature 73.4 ° |

Member Information

| Dongguan Fukuang Plastic Technology Co.,Ltd. | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13798901276 |

| Contact: | Vicky Li (Sales) |

| Last Online: | 29 Jul, 2019 |

Related Products of this Company

-

Injection grade POM GH-25D acetal

US $2

-

Engineering plastic Solvay Technyl A 216

US $1.8

-

Nylon66 BASF Ultramid A3WG7 BK00564 35%

US $3

-

Polyplastics POM GH-20 Resin

US $4

-

High-performance modified PC resin for

US $1.5

-

Plastic Molding Raw Material ABS

US $2

-

PC resin for light diffusion special

US $2

-

High-performance modified PC resin for

US $1

-

BASF Ultramid B3EG3 15% Glass Filled PA6

US $2.8

-

Black Masterbatches

US $2.2