| Model: | - |

|---|---|

| Brand: | DOINGGROUP |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Energy / Other Energy |

| Label: | tyre pyrolysis plant , waste plastic , waste rubber |

| Price: |

US $50000

/ pc

|

| Min. Order: | 1 pc |

Product Description

Pyrolysis can break larger molecules into smaller molecules in presence of heating. Doing waste tyre pyrolysis plant do take advantage of this theory ,which can convert waste tire into industrial fuels like pyrolysis oil, carbon black ,steel wire and uncondensable gas.

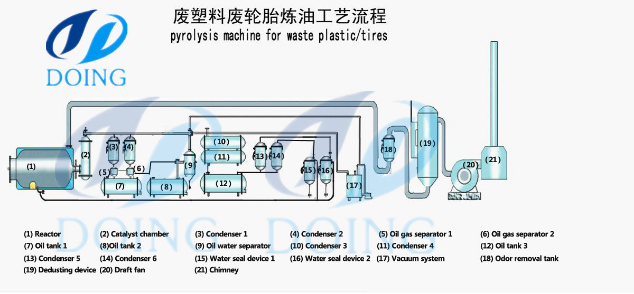

Waste tyre pyrolysis plant working process:

Firstly , feed waste tire into the reactor via an automatic pusher.

Secondly, when the reactor is heated,the waste tire in the reactor is subjected to thermochemical treatment to crack oil and gas.

Once again ,the cracked oil and gas will enter the condensing system.After being cooled, it will be liquefied into liquid fuel and fall into the tank .At the same time ,the non-condensable gas will be used to heat the reactor .

Finally,the smoke generated during the combustion process is filtered and free of contamination. After the reactor is cooled, carbon black will be discharged automatically, and worker could opened the door of reactor to take out of steel wire.

Four productscan be obtained by using the waste tyre pyrolysis plant :

Fuel Oil (45% to 52%)

The main application of oil products produced by our pyrolysis plant is the fuel oil that is wide used for industrial and commercial purposes, such as power plant factory, glass factory, cement factory, ceramic fatory.

Exhaust gas (About 10%)

We get about 10% pyrolytic gases during pyrolysis process. The main component of this gases are methane (CH4), so we can not condense and store this gases. We use this gases to heat the reactor and we can use exceed gases for other heating application.

Steel Wire (12% to 15%)

The third product of waste tyre pyrolysis plant is steel wire, the quantity of steel wire is about 10% to 15% according to tyre quality. It is very easy to sell steel wire scrape in local market.

Carbon Black (30%)

The second product of pyrolysis plant is carbon black. The quantity of carbon black is about 30% to 35% according to tyre quality. Carbon black can be used to make electric cable jacketing, black nylon bag, rubber additive

Here I will make a profit analysis on waste tyre pyrolysis plant :

1.45% fuel oil :4.5T, calculated at 400 USD per ton ,4.5T *400 USD =1800 USD

2.30% carbon black :3T

Carbon black have two uses:

- direct sales :80 USD per ton ,3T*80 USD =240 USD

- refined milling : calculated at 320 USD per ton, 3T* 320 USD =960 USD

3.15% steel wire : 1.5T, calculated at 128 USD per ton ,1.5T *128 USD =192 USD

The expense include the cost of buying waste tyres, heating fuel , power consumption , water consumption and required workers. The profit we can get is about 2000 USD a day.

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email: oilmachine@doinggroup.com

http://www.doinggroup.com

http://www.china-doing.com

http://www.wastetireoil.com

http://www.continuouspyrolysisplant.com

| Payment Terms: | TT/LC/DP/DA |

|---|---|

Member Information

| Henan Doing Mechanical Equipment Co., Ltd | |

|---|---|

| Country/Region: | He Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 13526692320 |

| Contact: | Bonnie (SEO) |

| Last Online: | 12 Nov, 2019 |