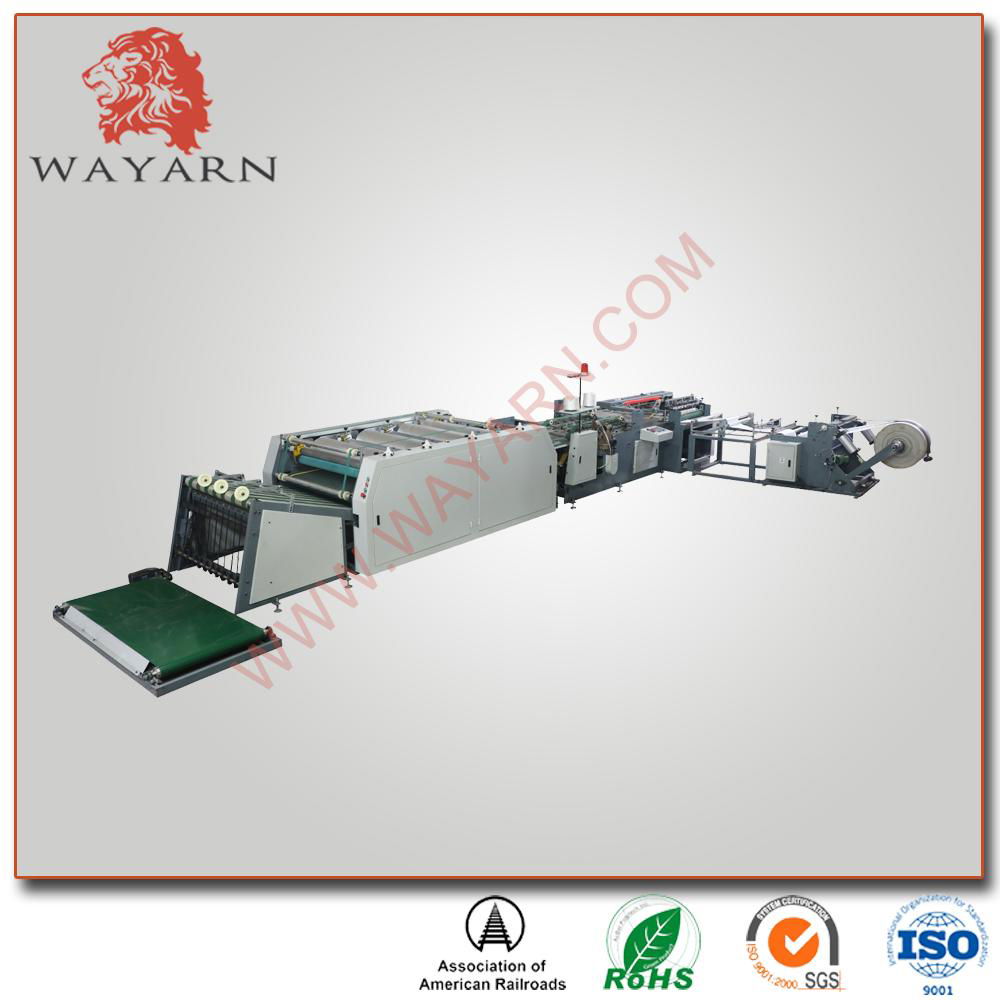

| Model: | WYCM-1600 |

|---|---|

| Brand: | WAYARN |

| Origin: | Made In China |

| Category: | Industrial Supplies / Other Industrial Supplies |

| Label: | Automatic machine , Cutting machine , Sewing machine |

| Price: |

US $1000

/ Sets

|

| Min. Order: | 1 Sets |

Product Description

Automatic cutting & sewing & printing integrated machine

♦ Full Automatic

♦ High speed, Easy to operate

♦ Stability, Fixed length cut

♦ Easy maintenance

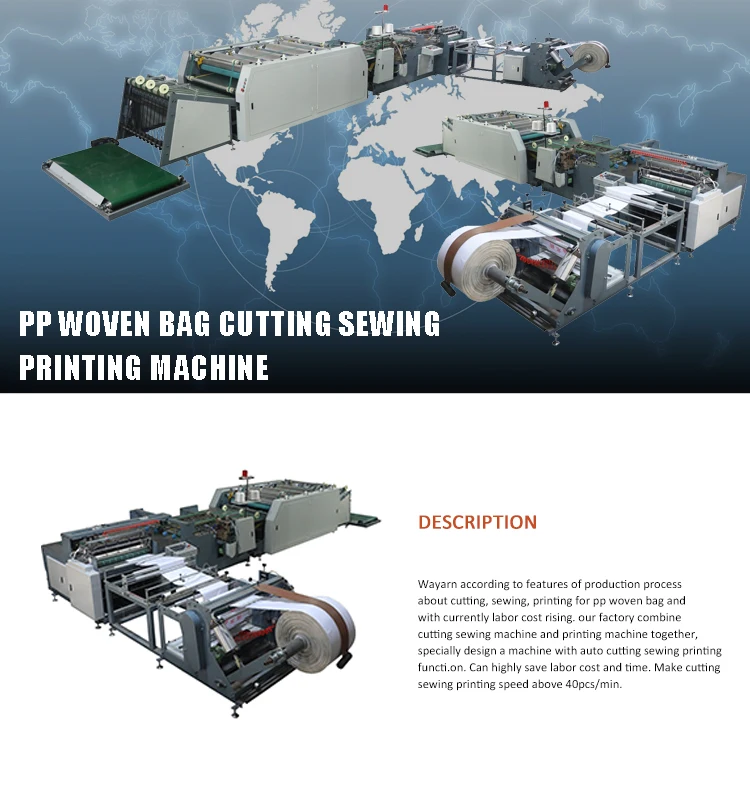

Machine Descripation

Wayarn Auto Cutting and Sewing and Printing Machine use Touch Screen Setting , Imported PLC .Automatic finished Blank PP Woven bag setting length for cutting , sewing and Printing .

Machine Advantages

Advantages of ultrasonic pp woven bag cutting & sewing printing line machine non woven bag machine

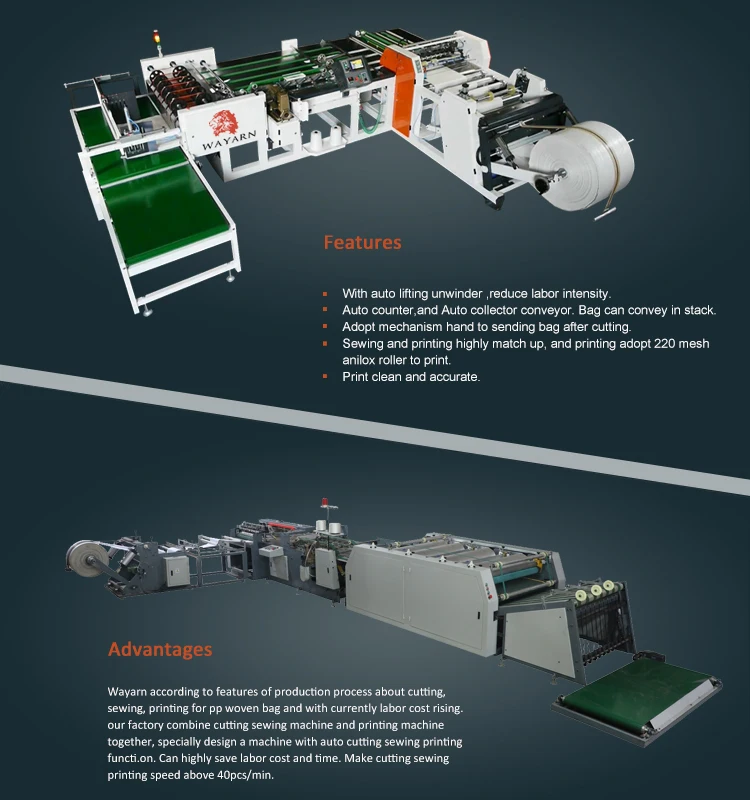

♦ Counters could be prefabricated at the ringbell.

♦ Printing roller could be automatic tracking.

♦The ink roller and printing plate could be on-off

♦ After delivery prolong, dry function

♦ Pneumatic separation, the noise lower, save power

♦ Easy operation, flexible starting, color accuracy

♦ The counter can set printing quantity according to the requirement

♦ Anilox roller transfer ink, ink well-distributed, save 35% ink, enhanced the degree of printing finish

♦ Automastic completion of woven bag cylider fixed length cutting, ,folding, sewing,collecting bag and save labor.

♦ Automatic counting of woven bags, can be a whole stack of feeding, the number of adjustable.

♦ Using the PLC control and servo motor drive, control the length of bag very accuratly

♦ Pneumatic coil, photoelectric tracking edge correction accuracy, simple operation,reliable quality, stable performance, low failure rate.

♦ The bottom of woven bag could be single & double folding, folding uniform, head with adjustable lenght.

Technical Parameters

Full-auto pp ultrasonic sewing machine with printing

♦Auto pneumatic roll loading

♦Newlong sewing machine ,made in Japan

♦Printing length controlled by servo system

♦Hot cutting auto mouth open

♦Cold cutting servo system control (optional)

♦PLC centralized control, operation monitor

♦Parameter setting ,display ,record

♦The NBR print roller with Metal Anilox Roller which thickness is 10mm

♦Inverter control speed

♦Auto bag counting .folding ,transportation

FAQ

Automatic cutting & sewing & printing integrated machine

♦How about the installation and deb ing?

We take charge of transporting equipment to the designated place according to model and quantity stipulated in the contract, and promise to finish the equipment installation, deb ing,starting and operation as time prescribed by both parties.

♦How about the technical training

After normal operation of equipment and acceptance, we will offer maintenance and operation trainings on the spot for the unit without personnel constraints until they master the maintenance and operation.

♦How about the qulity?

We guarenteen the best price and the high quality for the customer.

♦How about the test?

After installation and deb ing of equipment, both parties can carry out the acceptance test

♦What is your terms of payment ?

Validity: within 30 days

PAYMENT TERM: 30% DEPOSIT BY T/T BEFORE PRODUCTION, 70% BALANCE BEFORE

LOADING.

Company Informations

| Payment Terms: | TT/LC/DP/DA |

|---|---|

Member Information

| Wayarn Industry Co.,Ltd | |

|---|---|

| Country/Region: | Zhe Jiang - China |

| Business Nature: | Manufacturer |

| Phone: | 15356208882 |

| Contact: | Mia Zhang (Sales Manager) |

| Last Online: | 16 May, 2018 |

Related Products of this Company

-

Woven bag cutting machine sewing machine

US $1000

-

Single Host Dual Die Head Laminating

US $1000

-

Hot sales LDPE PP EVA EAA extrusion

US $1000