| Model: | Hanking1 |

|---|---|

| Brand: | Hanking |

| Origin: | Made In China |

| Category: | Services / Service Projects |

| Label: | Plastic Injection Mo , plastic mold , injectioin mold |

| Price: |

US $1000

/ set

|

| Min. Order: | 1 set |

Product Description

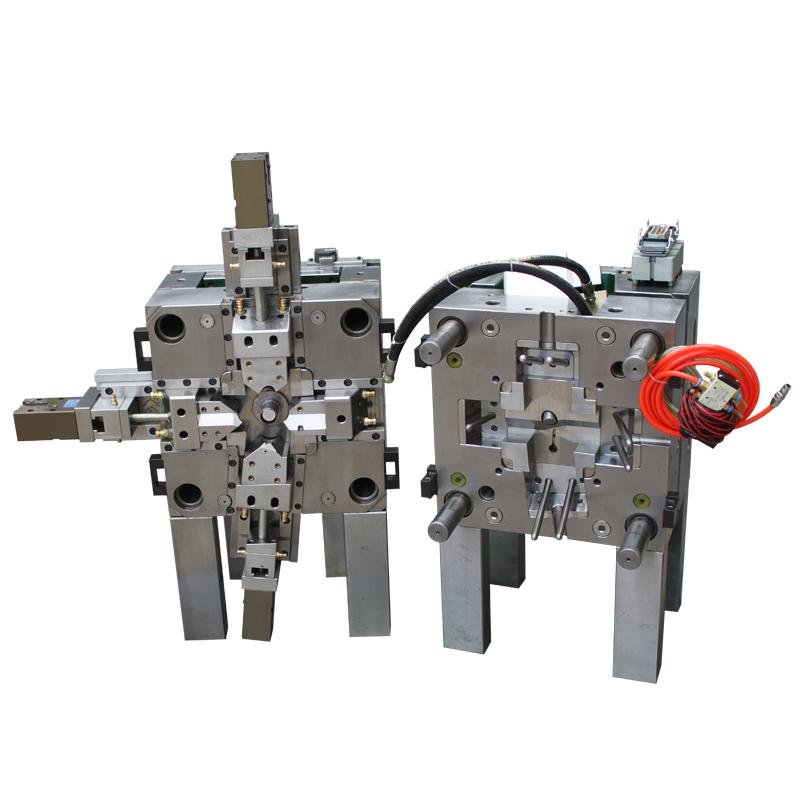

Plastic Injection Mould Shaping Mode and Aluminium Product Material plastic mold

1:Mould Base Standard : LKM Brand, Hasco, DME ect ;

2:Cavity/Core Material : 2738,2343,DIN-1,S130, 2344,738H,718,8407,S136,NAK80,P20,KD-61,NIMAX ect ;

3:Hardness of the steel : 20-60HRC ;

4:Cavity Qty : Single-cavity / Multi-cavity ;

5:Runner : Yudo/ Mastip/ HASCO/ DME/ MOLD-MASTER Hot runner or Cold runner ;

6:Gate : Submarine gate, side/edge gate, direct gate ect ;

7:Plastic Part Materials: PA, POM, ABS, PP, PET, PC, PE, HDPE, PA66+GF, PVC, TPE etc ;

8:Mould Life Time : 500,000-1,000,000shots as per customers' requirement ;

9:Quality : ISO9001:2000 Certificate ; ISO14001,ISO TS-14969.

10:Lead Time : 25-45 workdays based on the different products ;

11:Package : Wooden Case Package or As per Customers' Requirement ;

12:Price Terms : FOB shenzhen and hongkomg Port, China ;

13:Payment term: T/T at sight; Western Union

14: Specialize in design and the manufacture of Plastic Injection Mould and tooling for Automotive, Electronic equipment ,Medical Products, Double Color part and other.

15: OEM & ODM orders are welcome

HANKING MOULD (SHENZHEN) CO.,LTD has been a leading plastic mould manufacturer since 1996 and has more than 800 employees. Now we become a world-class OEM & ODM company, our satisfied customers are from all over the world.

We specialize in:

1:Research&Development in electronic product; (Total 18 Engineers)

2:Mould Manufacturing :700+set moulds per year, the max tooling size: L1400*W1000*H1200mm;

3:Injection Molding: More than 145 injection machines (90-1000ton)

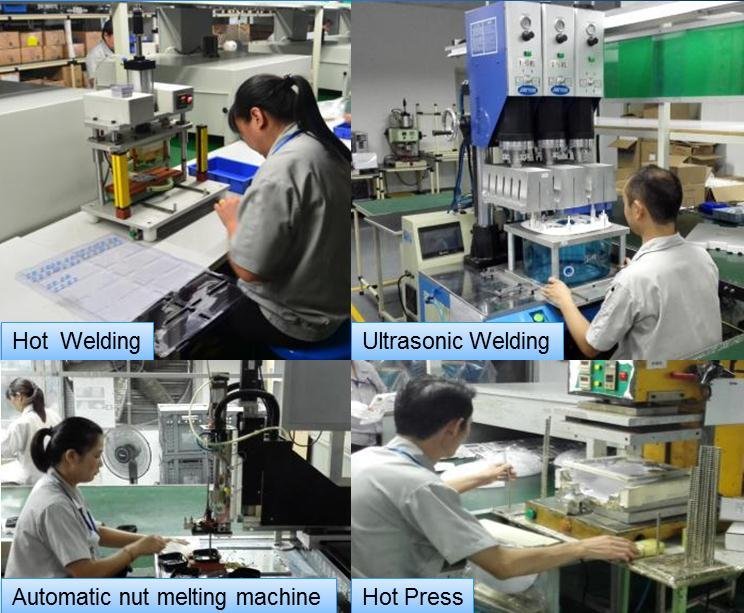

4:Secondary Process: (Painting, Silk Printing, Pad Printing, Engraving, Laser Etching, Hot Welding, Ultrasonic Welding etc.)

5:Product Assembly (8 Assembly lines)

6.Mould involved:

Automotive, Electronic equipment, Home appliance. Medical devices,

communications parts, printers parts, POS machine parts, OA parts.2K molding, over molding, insert molding.

7.Diversity of OEM & ODM products such as Air Purifier, Smart Robot, Water purifier, wifi box, wifi router,Smart Blueteeth Speaker, Sweeping Robot, Hydrogen Water Cup, Humidifier, Fruits and Vegetables Detoxification Cleaner and so on.

8:Quality Assurance Certificates are:

A: ISO9001:2008

B: ISO/TS16949:2009

C: ISO13485:2012

D: ISO14001:2004

Packaging & Shipping

1,.the surface of core and cavity will be covered by antirust.

2.the mould surface will be covered by butter.

3.the mould will be packed by plastic membrane.

4.the mould will be put into wooden case.

5.some other spare parts and all date sheet(2D/3D drawing and revised drawing)will be put into the wooden case together with mould,there are lifting bolt,water nozzle,water hose,ejector pin etc.

| Payment Terms: | TT/LC/DP/DA |

|---|---|

Member Information

| Hanking Mould (Shenzhen) Co.,LTD | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 89572498 |

| Contact: | Sunny Lau (marketing manager) |

| Last Online: | 13 Sep, 2018 |