High-temperature Burner-Comflame

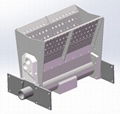

HB Series Comflame Burner

Comflame burner is an industrial application burner designed for high temperature. It is widely used in various industrial applications, such as waste incinerator (RTO/TO), thermal treatment furnace, non-ferrous metal smelting furnace, tunnel furnace, calcinator, hot air furnace, drying furnace, and cracking furnace.

Product Features

1. It applies to the furnace for which the maximum temperature is 1100ºC;

2. High heat transmission efficiency, even furnace temperature;

3. It applies to the working conditions under which high temperature and low temperature can be changed flexibly;

4. The fuel or air volume can be adjusted flexibly so as to meet requirements under all kinds of working conditions;

5. Low CO and NOX discharge;

6. The regulating ratio of the burner can reach 40:1;

7. Eight models with different powers can be selected.

Product Parameters

| Typical Parameters |

| Burner Model |

Rated Power (kW) |

Operation Conditions at Normal Temperature |

| Combustion aided by normal temperature air(20ºC) |

Combustion aided by preheated air (320ºC) |

Flame length * (m) |

Differential pressure at burner nozzle (kPa) |

Combustion air flow ** (m3/h) |

Allowable percent of excessive air (%) |

| CFG-2 |

60 |

40 |

0.3 |

0.5 |

15 |

850 |

| 3.5 |

41 |

860 |

| 7 |

59 |

1250 |

| CFG-3 |

100 |

67 |

0.5 |

0.5 |

25 |

1500 |

| 3.5 |

70 |

1780 |

| 7 |

99 |

1675 |

| CFG-4 |

170 |

114 |

0.6 |

0.5 |

41 |

1400 |

| 3.5 |

115 |

1100 |

| 7 |

162 |

1500 |

| CFG-5 |

270 |

181 |

0.9 |

0.5 |

66 |

620 |

| 3.5 |

188 |

490 |

| 7 |

267 |

460 |

| CFG-6 |

430 |

288 |

0.9 |

0.5 |

104 |

730 |

| 3.5 |

294 |

730 |

| 7 |

414 |

410 |

| CFG-7A |

760 |

509 |

1.8 |

0.5 |

183 |

2000 |

| 3.5 |

518 |

1000 |

| 7 |

734 |

450 |

| CFG-7B |

950 |

637 |

1.8 |

0.5 |

228 |

2700 |

| 3.5 |

644 |

875 |

| 7 |

913 |

500 |

| CFG-8 |

1200 |

804 |

2.1 |

0.5 |

297 |

2000 |

| 3.5 |

840 |

2210 |

| 7 |

1187 |

1350 |

* - The flame length is measured when the burner pressure is 0 and the air pressure on the burner is 7kPa.

** - The flow of the combustion air in the table is the ideal value. 20% additional fans should be configured when configuring the combustion air fans. |

Important Notes for Type Selection

Control Mode of Burner

Comflame burners are designed with a wide range of combustible gas regulation ratio. Stable combustion can be ensured in case of excessive combustion air or excessive combustion gases. Several control methods can be used to regulate the combustible gases, e.g. diaphragm regulation, mechanical regulation and electronic regulation.

Ignition and Flame Detection

Comflame burners are designed with three independent holes, which are used to install the ignition nozzle, flame detector and observation window. Optional flame detectors include the ultraviolet flame detector or flame ion detection rod. The installation positions of the ignition nozzle, flame detector and observation window can be adjusted based on actual operation conditions to ensure higher stability and accuracy of ignition and flame detection. Manual ignition using a torch is allowed in special cases. However, excessive flow of combustion air should be avoided in this case. Otherwise, ignition may fail.

Type Selection of Refractory Bricks

| High-speed outlet refractory brick |

|

Proper refractory bricks can be provided for Comflame burners based on actual operation conditions. HB type high-speed outlet refractory bricks can provide high-speed flame. However, more stringent requirements must be met for their installation to protect the burner and the surrounding equipment. Therefore, the selection of refractory brick styles and proper installation are key to the safety operation.

Type Selection in Pre-heated Air Environment:

The Comflame burner can use the environment air and high-temperature preheated air (up to 320ºC). In the case of pre-heated air environment, see the rated power values under "pre-heated air combustion" (320ºC) in the typical parameter sheet to select proper types.

Outside Dimensions

| Installation thread hole Combustion air inlet Gas inlet Pressure hole Observation window Observation window installation hole Ignition nozzle installation hole Flame detector installation hole |

| Burner Model |

Outside Dimensions (unit: mm) |

Interface Dimensions (unit: inch) |

Net Weight (kg) |

| A |

B |

C |

D |

E |

F |

G |

J |

K |

L1 |

L2* |

M |

P |

Q |

| CFG-2 |

300 |

134 |

127 |

216 |

133 |

67 |

12 |

111 |

215 |

262 |

228 |

1/4 |

11/4 |

1 |

34.5 |

| CFG-3 |

264 |

11/2 |

| CFG-4 |

52 |

213 |

269 |

2 |

11/4 |

| CFG-5 |

21/2 |

11/2 |

| CFG-6 |

140 |

3 |

| CFG-7A |

342 |

156 |

178 |

254 |

177 |

67 |

14 |

148 |

278 |

356 |

1/8 |

4 |

21/2 |

59 |

| CFG-7B |

| CFG-8 |

273 |

279 |

357 |

6 |

63 |

| * -L2 is ordinary refractory bricks. The L2 size of HB refractory bricks is 343mm. |

Burner Installation

Requirements for burner installation hole

| Edge length of refractory brick |

Before installing the burner, drill square holes at the furnace wall based on refractory brick size. The hole size must be exceed the max diameter of the brick by 12mm. The recommended range of size for D0 is: mm.

The length of a standard refractory brick is 228mm. The length of HB refractory wall is 343mm. When the furnace wall thickness is greater than the refractory brick length, a flared mouth that is 30°against the horizontal should be kept on the end surface inside the furnace wall that is beyond the brick (shown on the right) to protect the furnace wall.