Product Name:

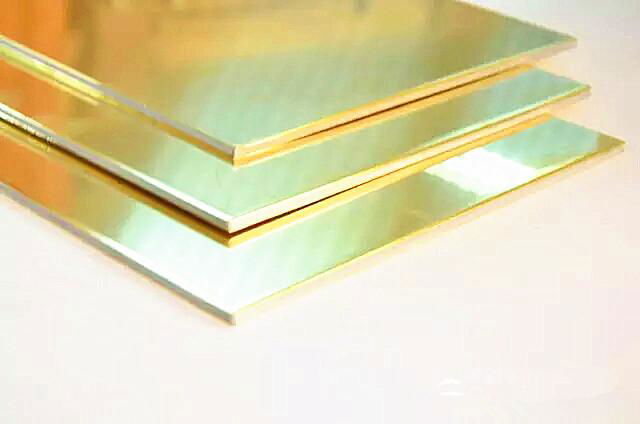

Copper Composite Panel, Brass Composite Panel, Copper Composite Panel, Copper Composite Material, Copper Panel, Copper Cladding, Natural Copper Panel, Copper Clad Sheet, Copper Facade Cladding, Copper Wall Panel, Copper Aluminum Composite Panel, Copper ACP, 2mm Copper Sheet, copper composite, 4mm copper composite panel, copper honeycomb panel, copper facade cladding, copper wall panel, brass sheet, 3mm copper sheet.

Introduction & Basic Information:

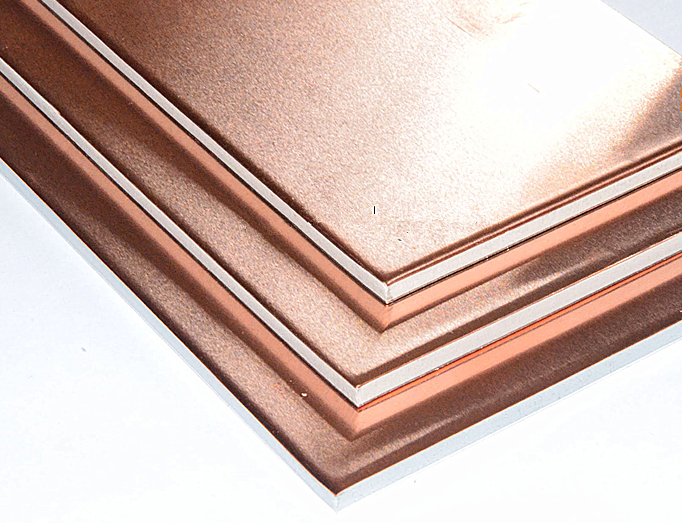

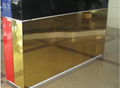

Copper Composite Panel combines the natural beauty of cooper with the advantage of composite panel, making it a new innovative material for architects.

Advantage of opper Composite Panel:

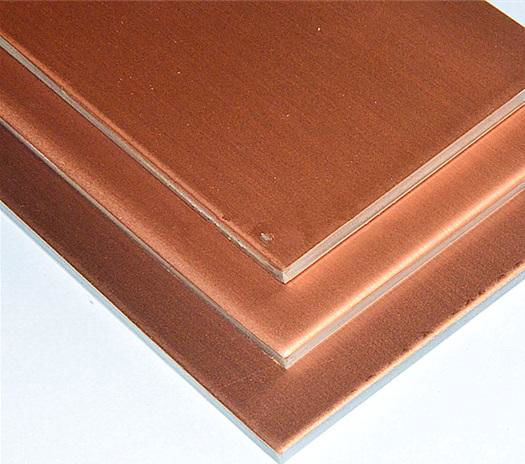

1) As time goes on the Copper skin will be oxidized and form a beautiful patina on the surface, giving the building a special and eye-catching classic look.

2) The flatness of Copper Composite Panel is better than ordinary Aluminum Composite Panel, making it also an idea wall cladding material.

3) Cost-Effective: Comparing to solid Copper Panel, the cost for Copper Composite Panel is about 60% lower.

Specification:

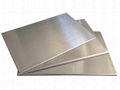

Total Thickness: 4mm

Copper Thickness: 0.5mm

Width: 1000mm

Length: Any up to 6000mm

| Copper Composite Panel |

| Total Thickness |

4mm |

| Copper Thickness |

0.5mm |

| Width |

1000mm |

| Length |

Any up to 6000mm |

Characteristics

Smooth surface coating

Excellent impact resistance

Outstanding weather & UV resistance

Light weighted

Cost efficient

Good heat & sound insulation

Easy to process, install and maintain

Fabulous dimensional stability

Splendid corrosion resistance

Diversified colors

Recyclable

Applications:

Facade cladding, curtain wall cladding, interior wall decoration,

Renewal of old building facade, signboard, furnitures, truck box, etc.

Technical Data:

| 70% HNO3 30mins |

ΔE< 5% |

|

| Boiling test |

Bended sheets 1.0T after 5 minutes in boiling water |

without cracks |

|

| Tensile Strenght |

155-180(Mpa) |

≥155 |

|

| Yield strength |

≥130Mpa) |

≥130 |

|

| Elongation |

≥3% |

|

≥3% |

|

| This test resulte is randomly tested by internal QC department and result in average datebase. |

|

Painting: Kynar 500 PVDF resin with quality dying material only from PPG or Beckers.

2-3 coating system as one of PPG's authorized coater in China

Color remain bright and vivid after long time duration even under server weathering considtion.

Why Kynar 500 PVDF coating? The one and only resin human could find can survive server neveda desert environment. PPG is the oldest PVDF resion supplier in the world, and they are famous for colorful and durability of dying materials.

Color: More than 30 standard colors and customerized colors available. Strict ΔE control.

ΔE means the color coherence control in same or different batch, eash the pressue on client's stocking plan or supplying line.

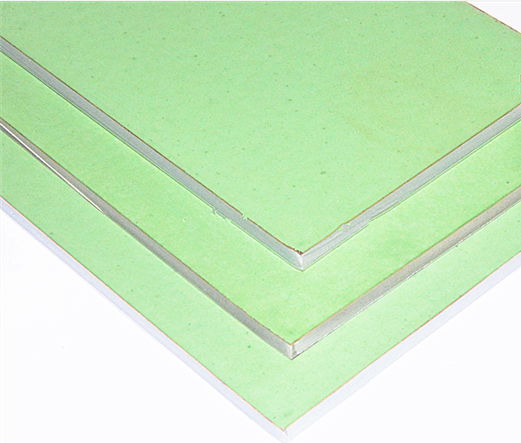

Core: PE flexible core or FR core