| Model: | - |

|---|---|

| Brand: | JY |

| Origin: | - |

| Category: | Electronics & Electricity / Motors |

| Label: | stator bonding , bonding stator , bonding lamination |

| Price: |

US $15

/ pc

|

| Min. Order: | 10 pc |

Product Description

We are ISO9001,ISO14001, TS16949 Certificated manufacturer who concentrate on high performance and high quality stator core lamination customization.

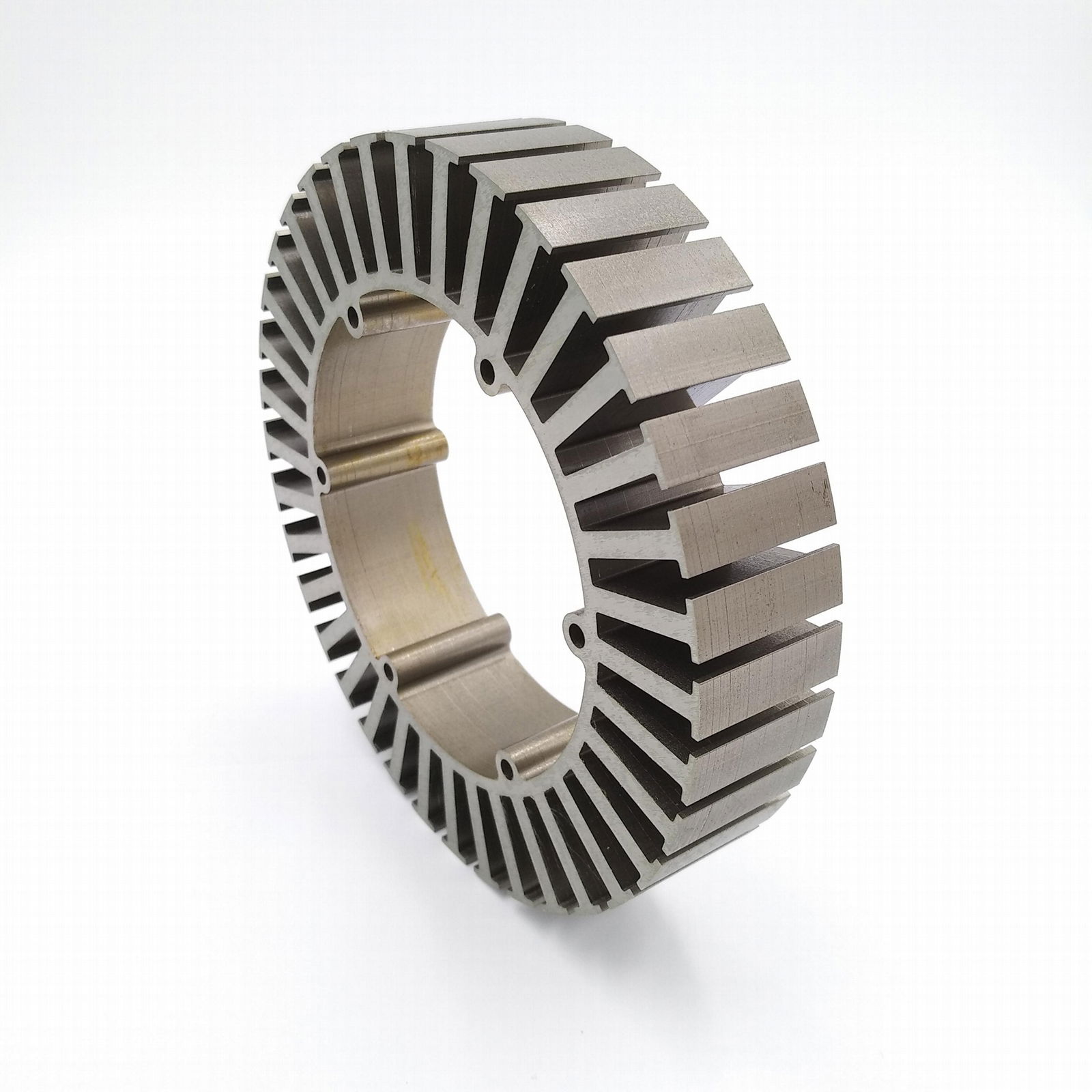

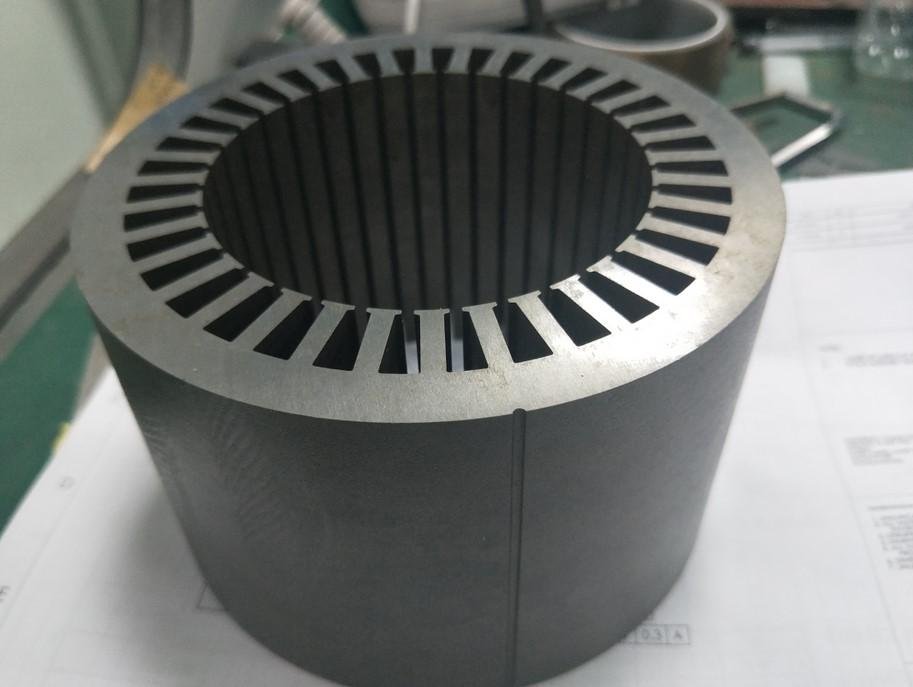

About Stator Bonding lamination:

Stator bonding is also called bonded stator lamination technology. it use high temperature glue or epoxy to realize the lamination process and ensure the stators do not need any interlock or welding to reach lowest iron loss and get highest motor efficiency. so it normally being used for high-end and high efficiency motors.

Our service:

- Motor stator and rotor core lamination with bonding, self-rivet point(interlock) and welding;

- Stator Punching and stamping mold design & manufacturing

- BLDC brushless dc motor stator and rotor core lamination

- Stator Prototype sample customization with wire cutting and laser welding.

- Stator epoxy coating with insulation powder, H Class.

- Manual stator copper wire coil winding for the prototype sample.

- Stator processing such as electrophoretic coating(rust against/rust protection) for stators and annealing

- Stator winding services if customer needed

Our advantage:

- More than 50 set of ready-made punching mold for selection to save your cost during your prototype sample stage and meet the needs of customer who needs small qty. order

- 20 years of manufacturing experience in the motor field

- Multiple kinds of punching die machine and testing equipment

- ISO9001, ISO14001,TS16949 Quality certificated

- Complete quality control system

- Our core has the best performance since lamination can be without any wielding and riveting point (Similar bonded stators).

Application:

- High Performance Brushless DC Motor;

- Generator;

- Servo motor;

- Electric motor;

- Drones, UAV and RC model motors;

- High accuracy automatic equipment;

- RC cars motors, RC boats motors, electrical bicycle motors.

Specification:

Silicon steel thickness:0.1mm/0.15mm/ 0.2mm/0.35mm/0.5mm

Silicon steel grade: TBD

Stator thickness: 2-200mm (can be customized)

Stator Outer Diameter: 10-300mm (can be customized)

Stator Inner Diameter: 2.8-180mm (can be customized)

Epoxy Coating color: green/blue

Bldc motor stator Coating temperature class: B,F,H Class can be selected.

Mold Type: Progressive stamping for stator rotor, single mold for stator rotor

Technology: Interlock rivet point, Chute, Patented lamination technology.

More details for us is: www#.jystator.#com (delete #)

contact with us paul#jystator.com (#=@)

Company Introduction:

We are professional 0.2mm BLDC motor stator and rotor lamination manufacturers who provide BLDC motor stator stamping mold design & manufacturing, silicon steel stamping and lamination, motor stator core lamination, motor stator stamping and punching, motor stator epoxy coting service. Our stator core products mainly supply to Germany, Italy, US, Canada, Korea, Japan etc… used in the field of UAV, Drone, RC airplanes, RC automobile, RC boats, robots, automatic equipment etc…

| Payment Terms: | t/t |

|---|---|

Member Information

| shenzhen jiaye Industrial Equipment Co., Ltd. | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 96421004 |

| Contact: | zhang yu (sales manager) |

| Last Online: | 27 Nov, 2018 |