| Model: | 9472LE 9495 467 |

|---|---|

| Brand: | 3M |

| Origin: | Made In China |

| Category: | Packaging , Printing & Paper / Packaging Materials / Other Packaging Materials |

| Label: | die cut tape , 3M custom Tape , adhesive transfer ta |

| Price: |

US $0.5

/ roll

|

| Min. Order: | 1 roll |

Product Description

Die Cut Original 3M Double Coated High Strength 300LSE (Low Surface Energy) Acrylic Adhesive Transfer Tape 9472LE For Automotive

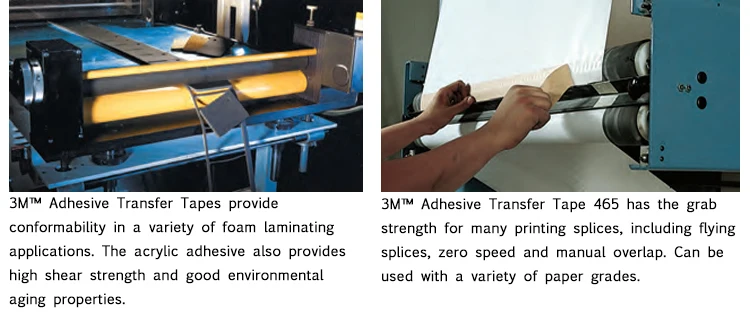

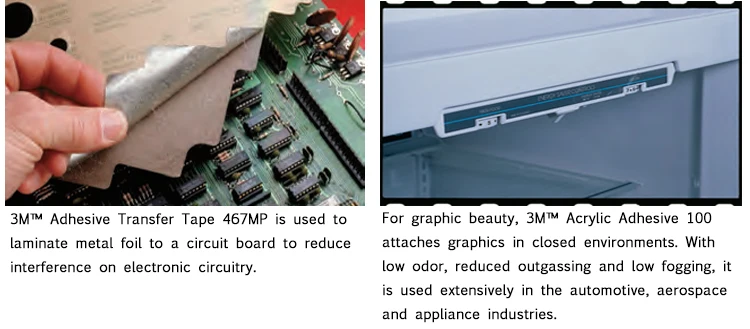

What are Adhesive Transfer Tapes?

Adhesive transfer tapes are double sided tapes comprised of a uniform layer of pressure sensitive adhesive pre-applied to a special release liner. For application, the tape is simply pressed, adhesive face side down, to a surface and the liner is peeled off to expose the backside of the adhesive for attachment. These adhesives and liners are available in a variety of thicknesses to meet a broad selection of applications in numerous industries.

Note:

Due to the limited number of words on this web page, we cannot provide more technical data and application details of all 3M adhesive transfer tapes sereies. If necessary, please contact us.

******************************************************************************************************************************************

3M High Strength 300LSE Adhesive Transfer Tape 9472LE for Automotive

Product Description

3M™ Adhesive Transfer Tapes with 3M™ Low Surface Energy Acrylic Adhesive 300LSE provides high bond strength to most surfaces, including many low surface energy plastics such as polypropylene and powder coated paints. The acrylic adhesive also provides excellent adhesion to surfaces contaminated lightly with oil typically used with machine parts.

Excellent Adhesion to a Variety of Surfaces

3M™ High Strength Acrylic Adhesive 300LSE is an acrylic adhesive family designed to provide very high bond strength to most surfaces, including a wide variety of similar and dissimilar materials. This includes most plastics, metals, glass, papers and painted surfaces. It features good chemical, solvent, moisture and humidity resistance. This adhesive can perform at temperatures ranging up to 300°F/148°C.

Specifications

| Adhesive Type | 3M™ Acrylic Adhesive 300LSE |

| Applications | Gasket Assembly, Large Surface Lamination Assembly, Mounting and Trim Attachment |

| Color | Clear |

| Face-Side Adhesive Thickness | 5.2 mil |

| Face-Side Adhesive Thickness (metric) | 0.13 mm |

| Face-Side Adhesive Type | 3M™ Low Surface Energy Acrylic Adhesive 300LSE |

| Indoor/Outdoor | Both |

| Industries | Appliance, Automotive, Construction, Converter Solutions, Electronics, General Industrial, Medical, Metalworking, Military, Military & Government, MRO, Oil and Gas, Paper, Signage, Specialty Vehicle, Transportation, Woodworking |

| Maximum Operating Temperature (Celsius) | 149 Degree Celsius |

| Maximum Operating Temperature (Fahrenheit) | 300 Degree Fahrenheit |

| Minimum Operating Temperature (Fahrenheit) | -40 Degree Fahrenheit |

| Position | Best |

| Primary Liner | 58# Polycoated Kraft Paper (PCK) |

| Primary Liner Color | 4.2 mil |

| Product Form | Each, Roll |

| Shear Strength at 72 Degrees F (22 Degrees C) | Medium |

| Specifications | Ford, GM, Nissan |

| Substrate 1 | Foam (EPDM - EVA - Neoprene - Nitrile Sponge Blend - Polyurethane, Ester), Foam (Melamine), Foam (Polyimide), Foam (Polyurethane, Ether), Foam (PVC), Glass (Inked Glass - Ceramic), LSE Plastics, Metal, Metal (Aluminum - Powder Coated - Copper - Stainless Steel - Zinc/Galvanized), Plastics/Composites (ABS - Carbon Fiber - Acrylic - Fiberglass - Polycarbonate - Polyester - Polyimide - Polystyrene - Rigid Vinyl), Plastics/Composites (Enamel/Epoxy Paints), Plastics/Composites (Glass Filled Nylon), Plastics/Composites (Nylon - PEEK - Polyethylene - Polypropylene), Plastics/Composites (Powder Coated Paints), Rubber (Buna Nitrile - Butyl - Neoprene - TPV), Rubber (EPDM), Rubber (Except EPDM), Rubber (Natural), Rubber (SBR), Woods (Veneer) |

| Substrate 2 | Foam (EPDM - EVA - Neoprene - Nitrile Sponge Blend - Polyurethane, Ester), Foam (Melamine), Foam (Polyimide), Foam (Polyurethane, Ether), Foam (PVC), Glass, Glass (Inked Glass - Ceramic), HSE Plastics and Glass, LSE Plastics, Metal, Metal (Aluminum - Powder Coated - Copper - Stainless Steel - Zinc/Galvanized), Paint, Plastics/Composites (ABS - Carbon Fiber - Acrylic - Fiberglass - Polycarbonate - Polyester - Polyimide - Polystyrene - Rigid Vinyl), Plastics/Composites (Enamel/Epoxy Paints), Plastics/Composites (Glass Filled Nylon), Plastics/Composites (Nylon - PEEK - Polyethylene - Polypropylene), Plastics/Composites (Powder Coated Paints), PTFE, Rubber (Buna Nitrile - Butyl - Neoprene - TPV), Rubber (EPDM), Rubber (Except EPDM), Rubber (Natural), Rubber (SBR), Woods (Veneer) |

| Substrates | EPDM Rubber, Glass, HSE Plastics and Glass, LSE Plastics, Metal, Oily, Paint, Paints (Powder Coat, Painted Metal, Composite Panel), PTFE, Rubber (Except EPDM), Smooth |

| Thickness | 5.2 mil |

| Thickness (Metric) | 0.132 mm |

Product Construction

| Product Number | Adhesive (Solvent Free) | Liner |

| 3M™ Adhesive Transfer Tape 9472LE | 5.2 mils (132 microns) 3M High Strength Acrylic Adhesive 300LSE | 4.2 mils (107 microns) 58# Polycoated kraft |

Details

Excellent bond to low surface energy substrates including powder coatings and plastics such as polypropylene (PP).

High adhesion to metals and high surface energy materials, making it suitable for bonding dissimilar substrates.

Adhesive provides excellent holding power and anti-lifting properties.

Good resistance to industrial chemicals, consumer chemicals, moisture and humidity.

Ideal solution for general purpose attachment and assemblies of a wide variety of materials.

Meets a wide variety of automotive and OEM specifications.

Our 3M™ Adhesive Transfer Tape 9472LE is a versatile, market proven, 5 mil (0.13 mm) transfer tape on a printed release liner. Featuring 3M™ 300LSE acrylic adhesive, this tape has a long and proven history of reliably bonding a wide variety of similar and dissimilar materials such as metals, most plastics, glass, papers and painted surfaces.

Versatile, Market Leading Performance

For applications requiring premium performance and a thicker profile than our 2 mil tapes, use our versatile 3M™ Adhesive Transfer Tape 9472LE. This tape is a market leading solution for bonding plastics in a variety of applications across a broad spectrum of industries. It offers good chemical, humidity and moisture resistance, as well as performance across a wide temperature range (from -40°F/-40°C to 300°F/148°C). The bond strength increases as a function of time and temperature, and has very high initial adhesion. This tape is supplied on a printed 58 lb. polycoated kraft paper liner ideal for die-cutting and converting applications. Part of the 3M™ High Strength Acrylic Adhesive 300LSE family, this tape is manufactured using a solventless manufacturing process. 3M™ Adhesive Transfer Tape 9472LE meets UL 969 (reference file PGGU2.MH26206).

Typical Adhesion Properties

Note: The following technical information and data should be considered representative or typical only and should not be used for specification purposes.

Peel Adhesion - ounces/inch (Newtons/100 mm) ASTM D3330, modified: 90° peel, 2 mil aluminum backing.

Typical Adhesion Chart

| 3M™ Adhesive Transfer Tape | 15 Minute Room Temperature | 72 Hour Room Temperature | |||

| Oz./In. | N/100 mm | Oz./In. | N/100 mm | ||

| Stainless Steel | 9472LE | 109 | 119 | 140 | 153 |

| ABS | 9472LE | 102 | 112 | 128 | 140 |

| Polypropylene | 9472LE | 115 | 126 | 136 | 149 |

Note: The following technical information and data should be considered representative or typical only and should not be used for specification purposes.

The properties defined are based on the attachment of impervious faceplate materials (such as aluminum) to a stainless steel test surface.

Bond Build-up: The bond strength of 3M™ Adhesive 300LSE increased as a function of time and temperature, and has very high initial adhesion.

Humidity Resistance: High humidity has a minimal effect on adhesive performance. No significant reduction in bond strength is observed after exposure for 7 days at 90°F (32°C) and 90% relative humidity.

U.V. Resistance: When properly applied, nameplates and decorative trim parts are not adversely affected by exposure.

Water Resistance: Immersion in water has no appreciable effect on the bond strength. After 100 hours at room temperature, the high bond strength is maintained.

Temperature Cycling Resistance: High bond strength is maintained after cycling four times through:

4 hours at 158°F (70°C)

4 hours at -20°F (-29°C)

4 hours at 73°F (22°C)

Chemical Resistance: When properly applied, nameplates and decorative trim parts will hold securely after exposure to numerous chemicals including oil, mild acids and alkalis.

Temperature Resistance: 3M™ Adhesive 300LSE is usable for short periods (minutes, hours) at temperatures up to 300°F (148°C) and for intermittent longer periods of time (days, weeks) up to 200°F (93°C).

Lower Service Temperature: -40°F (-40°C).

Product Features

• 3M™ Adhesive 300LSE is a hi-strength acrylic adhesive that provides a very high bond strength to most surfaces.

• Excellent bond to low surface energy plastics such as polypropylene and powder coatings.

• Excellent adhesion to lightly oiled surfaces typical of machine parts.

• Thickness range of 2.0 mils, 3.5 mils, 5.0 mils and 8.5 mils for use on smooth, or rough surfaces.

• Extremely smooth adhesive for excellent graphics appearance.

• Double linered for selective die-cutting.

• Polycoated kraft liner for die-cutting end tabs and waste removed nameplates on a common carrier.

• 3M™ Adhesive Transfer Tapes 8132LE and 8153LE are double linered for selective die-cutting.

Application Techniques

For maximum bond strength, the surface should be thoroughly cleaned and dried.

Typical cleaning solvents are heptane or isopropyl alcohol. Carefully read and follow manufacturer’s precautions and directions for use when using cleaning solvents.

Bond strength can also be improved with firm application pressure and moderate heat, from 100°F to 130°F (38°C to 54°C), causing the adhesive to develop intimate contact with the bonding surface.

Ideal tape application temperature range is 70°F to 100°F (21°C to 38°C). Initial tape application to surfaces at temperatures below 50°F (10°C) is not recommended for most pressure-sensitive adhesives because the adhesive becomes too firm to adhere readily. However, once properly applied, low temperature holding is generally satisfactory.

Application Ideas

• Plastic nameplates or graphic overlays for use on low surface energy plastics.

• Waste removed nameplates on a common sheet for ease of application.

• Attaching membrane switch assemblies to powder coated surfaces and low surface energy plastics.

• Graphic overlays with end tabs for easy liner removal.

• Graphic application to surfaces such as wood, fabric, plastic, where very high bond strength is required.

• Attaching identification material to lightly oily surfaces typical of machine parts.

Recommended Applications

| Bonding rough substrates such as textured plastics |

| Plastic to metal bonding |

| Consumer electronic device assemblies such as phones, tablets and wearable devices |

| Industrial electronic device assemblies such as workstations |

| Plastic assembly bonding in a variety of industries |

| Various assemblies in the automotive industry |

| Application and assembly of components on appliances |

| Medical equipment and device fabrication |

| General industrial applications such as trim attachment |

General Information

Processing:

Slitting and die-cutting: This adhesive is very aggressive and may be difficult to convert depending on your application requirements. Chilling the adhesive between 35°F and 50°F will improve the processability. In addition, dies can be lubricated with Laminoleum evaporative stamping oil, which is available from Metal Lubricants Company (708-333-8900), or with Lubri-Blade 907 from Ceramic Technologies Inc. (800-258-8495). You may also refer to our Technical Bulletin on 3M™ Adhesive

300LSE converting. (70-0707-6205-2)

Roll Laminating: A combination of metal and rubber rollers with moderate pressure is recommended. Note: Please refer to the Technical Bulletin on slitting. (70-0709-3905-6)

Storage

Store at room temperature conditions of 70°F (21°C) and 50% relative humidity.

Shelf Life

If stored properly, product retains its performance and properties for 18 months from date of shipment.

Adhesive Family and Features

| Adhesive Family | Features |

| 350 | • Best in class for high temperature resistance 350°F (177°C) and shear strength |

| • Excellent solvent resistance for harsh environments | |

| • Best for challenging applications | |

| 360 | • More strength with less adhesive |

| • Quick stick properties to many LSE substrates | |

| • Lowest ooze | |

| • Low odor | |

| • Excellent convertability (die-cut) | |

| 300LSE | • Best in class for oily substrates |

| • Thicker "Go To" tapes for LSE substrates | |

| • Good chemical and humidity resistance | |

| 300MP | • Multi-purpose use for many applications |

| • Bonds very well to foam, fabrics and many plastics | |

| • Economical attachments of graphics |

Note: This technical information and data should be considered representative or typical only and should not be used for specification purposes.

Member Information

| Shenzhen JX Electronic Materials Co., Ltd. | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 15820456989 |

| Contact: | Erica (Sales) |

| Last Online: | 16 Oct, 2018 |

Related Products of this Company

-

3M Sj3560 Clear Dual Lock Reclosable

US $4.5

-

3M protective Bumpon SJ5302A clear

US $0.05

-

3M 9088 High Performance Double Coated

US $1.2

-

3M SJ3780 SJ3741 SJ5408 Dual Lock Self

US $15

-

Die cut 5~610mm 3M VHB 5952 Black Heavy

US $1.2

-

Heavy Duty 3M 9448A Black or White Self

US $1.2

-

3M Dual Lock Reclosable Fasteners SJ3550

US $3.2

-

3M Bumpon SJ5303/SJ5003 Protective

US $0.05

-

3M Sj5312 Clear Bumpon Self-Adhesive

US $0.05