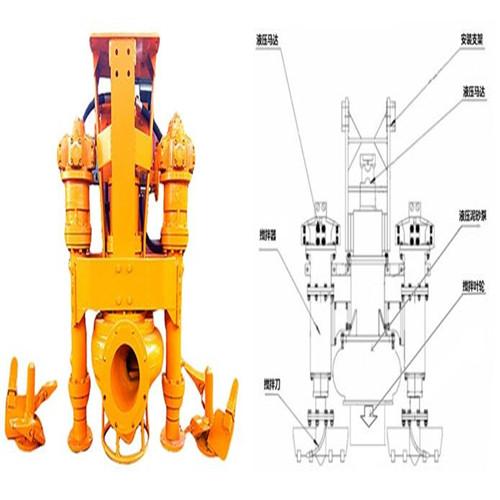

Hydraulic Dredge pump with agitator ——30 ton dredge hydraulic pump undefined we promise to use reliable quality and excellent service to win the trust of our customers! Hydraulic Dredge pump with agitator —— -- Hydraulic Dredge pump —————————————————————————————————————————————————————————————————————————————————————————————— It is divided into 12-inch, 10-inch, 8-inch, 6-inch, 4-inch and other large series of specifications. It is mainly used as an auxiliary device of excavators. When there is more water, silt, sand and gravel are thin, which are not conducive to excavating and are not convenient for transportation by vehicles, the hydraulic mud and sand pump is used to carry out the extraction operation, which greatly improves the working efficiency It is widely used in inland waterway dredging project, port mud and sand treatment, tailings pond sand extraction, mineral processing, municipal sewage and other desilting. WORKING CONDITIONS: 1. Hydraulic drive of excavator, this pump is suitable for 120,150,200,220,240,300,330,360,400 series excavators of Katel, Vîlvă, Komatsu, Tateyuku, Sumitomo, Shengang, Doushan, Hyundai, Xugong, Sany, Yuchai, Liugong, Longgong, Zhonglian, Shanzhong, Lingong, Shanhe, Xiagong, Jingong, etc. . 2, hydraulic pump station drive, the pump used by the hydraulic motor suitable for small, medium, large series of hydraulic pump station. Working principle: YSQ hydraulic sand pump with agitator is a new type of sand pump which is powered by hydraulic system and driven by motor. When working through the rotation of pump stirring impeller, energy transfer to the slurry medium, so that it produces a certain flow rate, driving solid flow, to achieve slurry transport. The hydraulic motor adopts famous domestic Quantitative Piston Motor and five-star motor. It has advanced and reasonable structure, good performance, high efficiency and stable work. According to the customer actual working condition, chooses the different displacement motor. Main Features 1, the bottom of the pump with a stirring impeller, and can be equipped with both sides of the agitator or cage, loose plate junction sediment, improve the concentration of extraction, to achieve automatic hinged suction. It also prevents the pump from being blocked by a large solid mass, allowing the solid and liquid to be fully mixed, making it easier to handle. 2. This pump can handle solid matter with a maximum particle size of 50mm, and the concentration of solid-liquid extraction can be over 70% . Note: Due to the different operating conditions, the output of the pump may also vary with the influence of factors such as the treatment medium, field operation, transportation distance, etc. . 3. The device is mainly installed on the excavator, the power is provided by the hydraulic station of the excavator, the free transfer can be realized, and the power source is a diesel engine. 4, flow parts: namely pump Shell, impeller, plate, mixing impeller are high chromium alloy, can also be customized other materials. Adopt unique sealing device, avoid frequent change of machine seal, improve work efficiency. UNDEFINED MAIN USES: 1, port, River, Lake and so on sand extraction, dredging, dredging, removal of silt, etc. . 2. mud-sand drainage, mud-mud drainage, mud-sand extraction, sand and gravel extraction, sea reclamation project. 3. Slag removal, slurry removal and all solutions containing solid matter from iron ore, tailings ponds, concentrators, etc. . 4, in metallurgy, steel and other industries used to absorb high concentration of tailings, waste slag and high-temperature iron slag, iron filings. 5, emergency drainage, cleaning up mud and so on. 6. It can be used in shallow water area and swampy land. It can be used in river dredging, lake development, wetland park construction, coastal beach development, Salt L. Development, tailings control and other hydraulic engineering and swampy land development projects. Pump selection: 1, according to the actual situation of users, to determine the required head, flow, transmission distance, etc. . 2, check excavator parameters, hydraulic system of excavator displacement, pressure and other parameters. 3, thereby the selection of hydraulic motor type; 4. Calculate the actual output power of the hydraulic system of the excavator and select the appropriate pump. Selection wechat phone: Dong: 18766163315 QQ: 651294757 can produce customized models, welcome to our factory to undertake large-scale submersible sewage pump and submersible cement pump maintenance, submersible motor manufacturing, import pump maintenance, etc. ! Compared with mechanical transmission and electrical transmission, hydraulic transmission has the following advantages: 1. Easy to realize stepless speed regulation. 2. transitive dynamic equilibrium. 3. High load carrying capacity. 4. Long life of components. 5. Easy to automate. 6. Easy overload protection. 7. Easy to standardize, serialize, and generalize. 8. Small, light and compact. Installation Step 1. First of all, ensure that the excavator has been installed hydraulic pipeline, ensure that the pipeline smooth. 2. Remove the dredge and connect the hydraulic mud pump to the excavator arm through the mounting plate. 3. Connect the inlet pipe, return pipe and overflow pipe. Note: to connect the oil pipe correctly, the overflow pipe can not be connected in parallel to the return pipe, and should be returned directly to the oil tank. 4. Install the mixer head and make sure it is not inverted. 5. Test Machine, if there is agitator head inversion, then the switch between the two agitators can be. One year warranty / Wooden case packing, can be customized according to customer requirements. Undefined, undefined, undefined, undefined