| Model: | 1.2*1219*2440 |

|---|---|

| Brand: | GAOBI |

| Origin: | Made In China |

| Category: | Construction & Decoration / Decoration Materials / Other Decoration Materials |

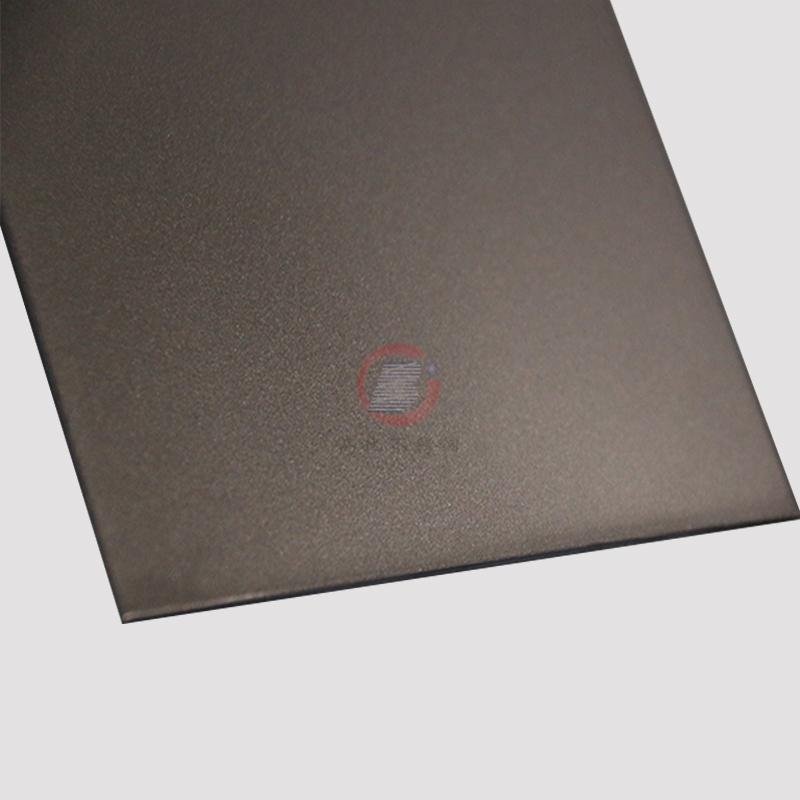

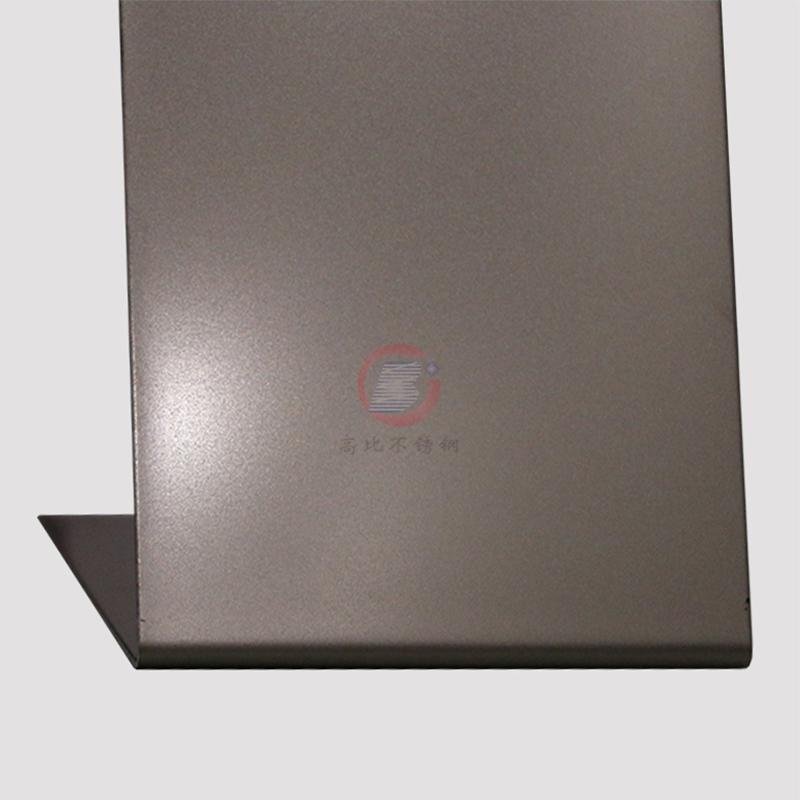

| Label: | champagne gold sheet , gold sheet , champagne sheet |

| Price: |

¥666

/ pc

|

| Min. Order: | 1 pc |

Product Description

8K board, light panels. It is polished on the surface of stainless steel plate with abrasive fluid through polishing equipment to make the surface of the plate as clear and transparent as a mirror. Its characteristics are wear resistance, pressure resistance, corrosion resistance, corrosion resistance has reached the international advanced level, and the color is gorgeous. The manufacturing process of stainless steel mirror panel can be divided into two ways: general grinding and fine grinding. Which of these two ways produces better mirror effect? This is judged by looking at the brightness of the mirror surface, and there must be fewer sand holes and grinding heads on the plate surface. Generally speaking, stainless steel plate is processed on polishing machine, the slower it goes, the more groups of grinding, and this effect will be very good. When stainless steel plate is processed with polishing equipment, the first thing is to sand the plate, and then put the stainless steel plate into the grinding fluid, which is through eight groups of thick and thin. With the same grinding head, the grinding process is basically the surface treatment of stainless steel plate. There is no depth in this process. This step is mainly to remove the oxide layer on the surface of stainless steel plate.

After the above process is washed and dried, the color stainless steel mirror panels are colored on the basis of stainless steel plate mirror panels. Now the high-grade color stainless steel mirror panels are processed by vacuum ion plating technology. We can even etch patterns on the mirror panel, and we can get various patterns and styles of pattern etching stencils. Colour plating: titanium gold, 24K gold, champagne gold, rose gold, bronze, brown gold, coffee gold, wine red, Black Titanium gold, purple red, sapphire, pink, violet, brown, black rose, seven colors, etc. Nowadays, with the rapid development of the national economy, it has been widely used in the fields of high-grade hotels, hotels, KTV, other entertainment places, building decoration, elevator decoration, industrial decoration, high-grade home decoration and so on.

Mirror panel features

1. without fading

Experiments show that polymer composite panels have better physical and chemical properties than traditional panels, ensuring that they are durable, and solving the phenomenon of color difference. Even in kitchens with complex environment, mirror panels also have the same color loss. This is similar to one of the characteristics of film mulching.

2. scratch resistance

High hardness and super abrasion resistance, no curing at room temperature.

3. acid, alkali and corrosion resistance

The super mirror plate can resist all kinds of acid and alkali, disinfectant washing and vow to carry out health in the end.

4. high surface smoothness

The mirror plate has high gloss effect. It will never appear orange peel phenomenon, and its surface is smooth and easy to clean.

5. rich paint film

This "lacquer" is not the "paint", the surface of the super mirror plate is resin material, and has the technology of lacquer type.

6. environmental health

Poor materials will have divergent substances (such as VOC) release, has a great impact on the human body. Mirror panel itself does not contain benzene and other vulnerable substances, through special light curing, forming a dense curing film, reducing the release of harmful gases from the substrate.

The manufacturing process of stainless steel mirror panel can be divided into two ways: general grinding and fine grinding. Which of these two ways produces better mirror effect? This is judged by looking at the brightness of the mirror surface, and there must be fewer sand holes and grinding heads on the plate surface. Generally speaking, stainless steel plate is processed on polishing machine, the slower it goes, the more groups of grinding, and this effect will be very good. When stainless steel plate is processed with polishing equipment, the first thing is to sand the plate, and then put the stainless steel plate into the grinding fluid, which is through eight groups of thick and thin. With the same grinding head, the grinding process is basically the surface treatment of stainless steel plate. There is no depth in this process. This step is mainly to remove the oxide layer on the surface of stainless steel plate.

After the above process is washed and dried, the color stainless steel mirror panels are colored on the basis of stainless steel plate mirror panels. Now the high-grade color stainless steel mirror panels are processed by vacuum ion plating technology. We can even etch patterns on the mirror panel, and we can get various patterns and styles of pattern etching stencils.

After the above process is washed and dried, the color stainless steel mirror panels are colored on the basis of stainless steel plate mirror panels. Now the high-grade color stainless steel mirror panels are processed by vacuum ion plating technology. We can even etch patterns on the mirror panel, and we can get various patterns and styles of pattern etching stencils. Colour plating: titanium gold, 24K gold, champagne gold, rose gold, bronze, brown gold, coffee gold, wine red, Black Titanium gold, purple red, sapphire, pink, violet, brown, black rose, seven colors, etc. Nowadays, with the rapid development of the national economy, it has been widely used in the fields of high-grade hotels, hotels, KTV, other entertainment places, building decoration, elevator decoration, industrial decoration, high-grade home decoration and so on.

Mirror panel features

1. without fading

Experiments show that polymer composite panels have better physical and chemical properties than traditional panels, ensuring that they are durable, and solving the phenomenon of color difference. Even in kitchens with complex environment, mirror panels also have the same color loss. This is similar to one of the characteristics of film mulching.

2. scratch resistance

High hardness and super abrasion resistance, no curing at room temperature.

3. acid, alkali and corrosion resistance

The super mirror plate can resist all kinds of acid and alkali, disinfectant washing and vow to carry out health in the end.

4. high surface smoothness

The mirror plate has high gloss effect. It will never appear orange peel phenomenon, and its surface is smooth and easy to clean.

5. rich paint film

This "lacquer" is not the "paint", the surface of the super mirror plate is resin material, and has the technology of lacquer type.

6. environmental health

Poor materials will have divergent substances (such as VOC) release, has a great impact on the human body. Mirror panel itself does not contain benzene and other vulnerable substances, through special light curing, forming a dense curing film, reducing the release of harmful gases from the substrate.

The manufacturing process of stainless steel mirror panel can be divided into two ways: general grinding and fine grinding. Which of these two ways produces better mirror effect? This is judged by looking at the brightness of the mirror surface, and there must be fewer sand holes and grinding heads on the plate surface. Generally speaking, stainless steel plate is processed on polishing machine, the slower it goes, the more groups of grinding, and this effect will be very good. When stainless steel plate is processed with polishing equipment, the first thing is to sand the plate, and then put the stainless steel plate into the grinding fluid, which is through eight groups of thick and thin. With the same grinding head, the grinding process is basically the surface treatment of stainless steel plate. There is no depth in this process. This step is mainly to remove the oxide layer on the surface of stainless steel plate.

After the above process is washed and dried, the color stainless steel mirror panels are colored on the basis of stainless steel plate mirror panels. Now the high-grade color stainless steel mirror panels are processed by vacuum ion plating technology. We can even etch patterns on the mirror panel, and we can get various patterns and styles of pattern etching stencils.

Member Information

| foshan gaobi stainless steel co.,ltd | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 18988653724 |

| Contact: | liu lei (manager) |

| Last Online: | 19 Nov, 2018 |