| Model: | FH2000-12 |

|---|---|

| Brand: | Feihong |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Welding Machinery |

| Label: | rebar cage welder , cage welding machine , bar cage welder |

| Price: |

US $55000

/ set

|

| Min. Order: | 1 set |

Product Description

Product Description

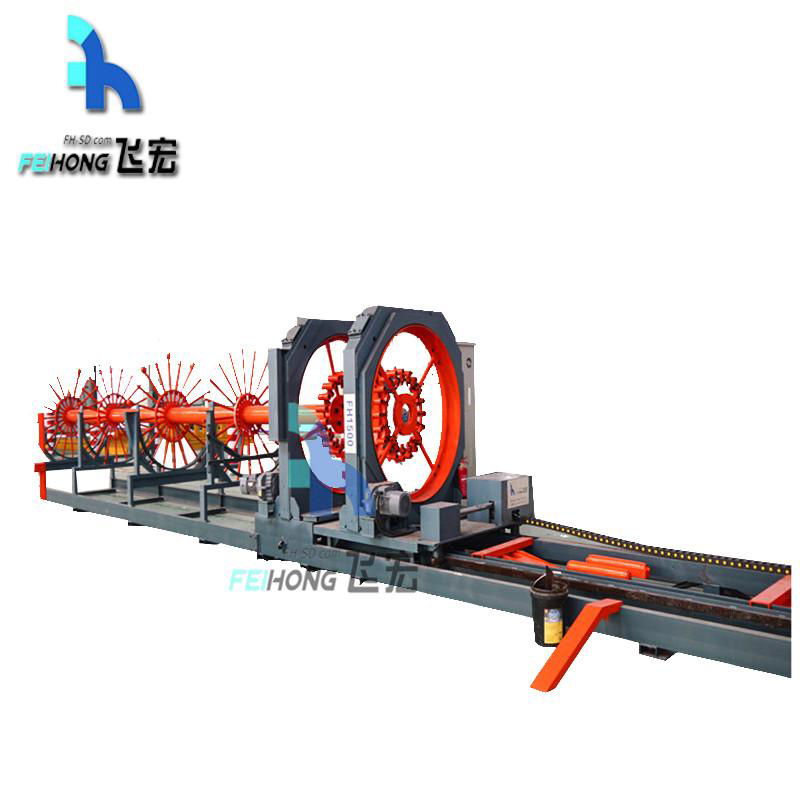

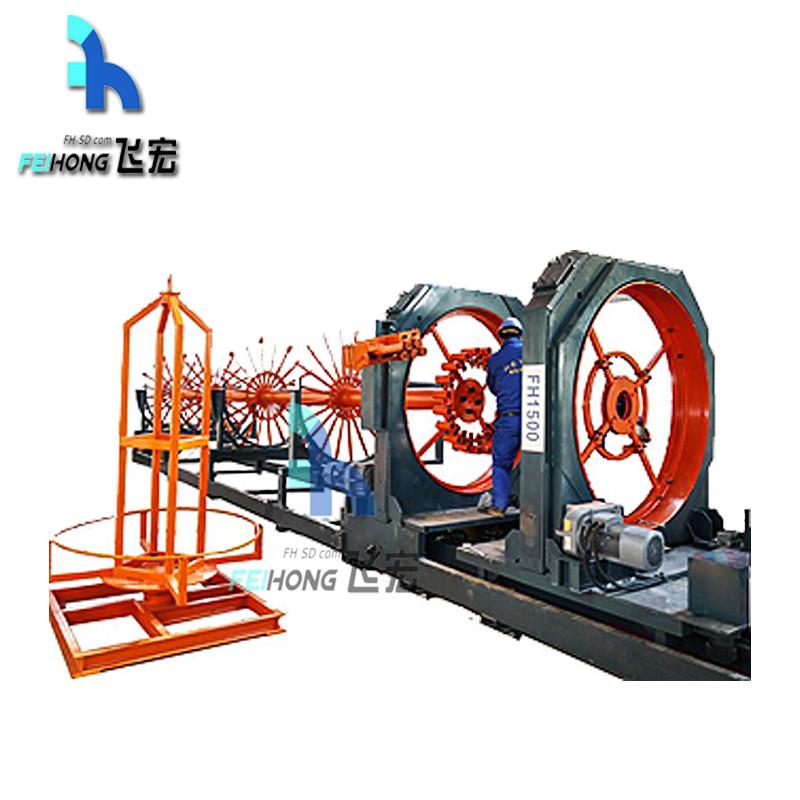

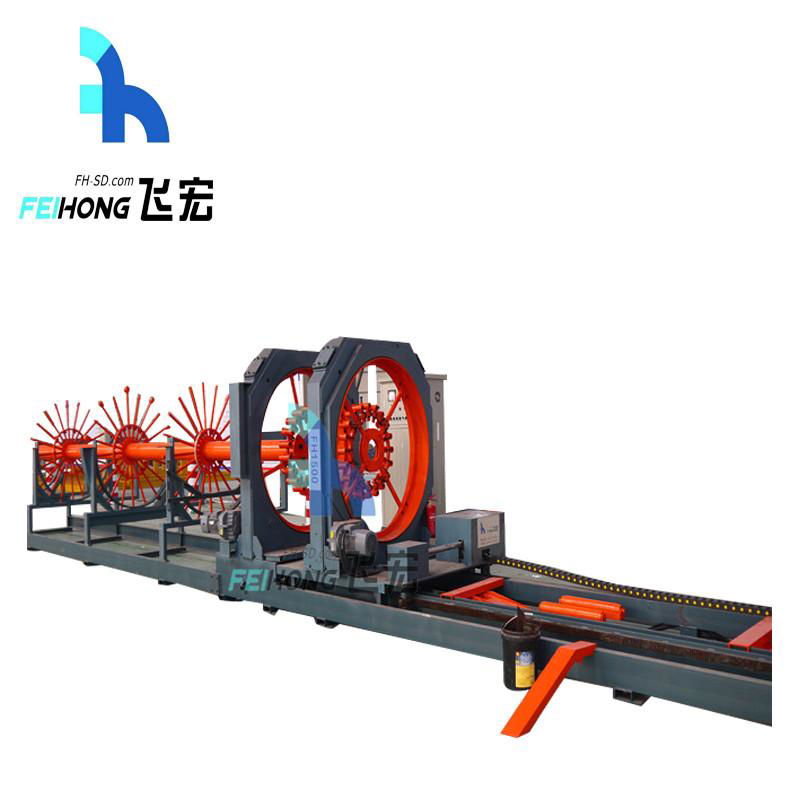

CNC Steel Bar Pile Cage Maker.

Feihong intelligent cage making machine is mainly used in Railway construction ,construction under bridge, highway,high-speed railway, steel plants in the field of building construction, the construction site and the prefabricated factory, it was been the most efficient and intelligent rebar cage processing equipment which most suitable for the construction site environment.

Product Details/Advantage

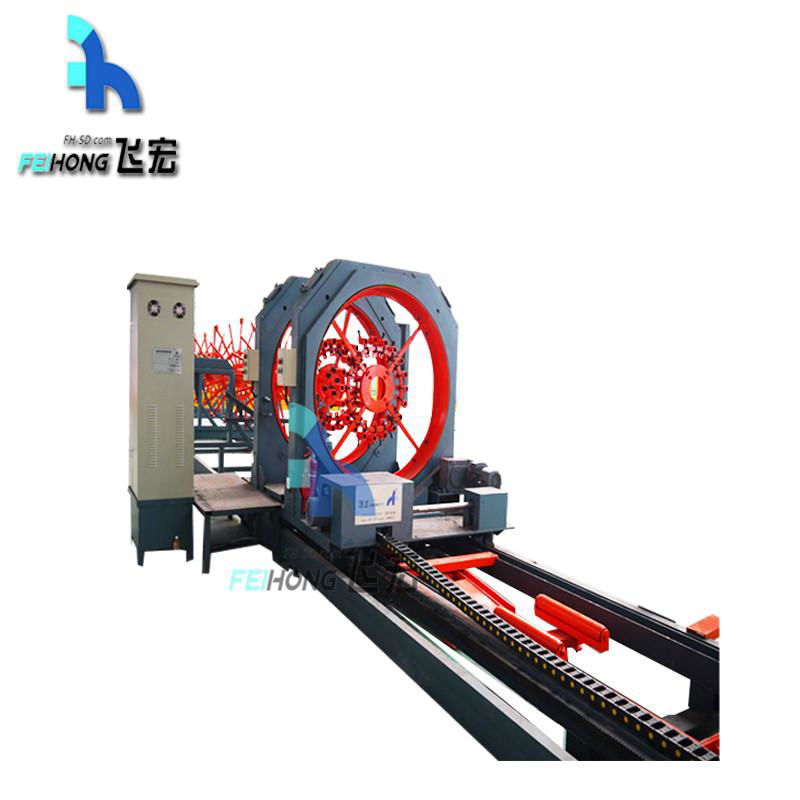

1.Control System: adopt Import ABB invertor and Panasonic PLC and Touch Screen electronic control components to ensure the stable operation of the equipment.

2.Easy to operate, user-friendly, three persons can work.

3.Cage diameter error control precision, the line rebar spacing error is small, can be controlled within 1cm; one-meter coils spacing error can be controlled within 5mm.

4.Can produce double longitudinal bar with double spiral wires high quality rebar cage

5.Excellent workmanship and strict quality inspection, high precision, wear resistance, the easy maintenance and long service life.

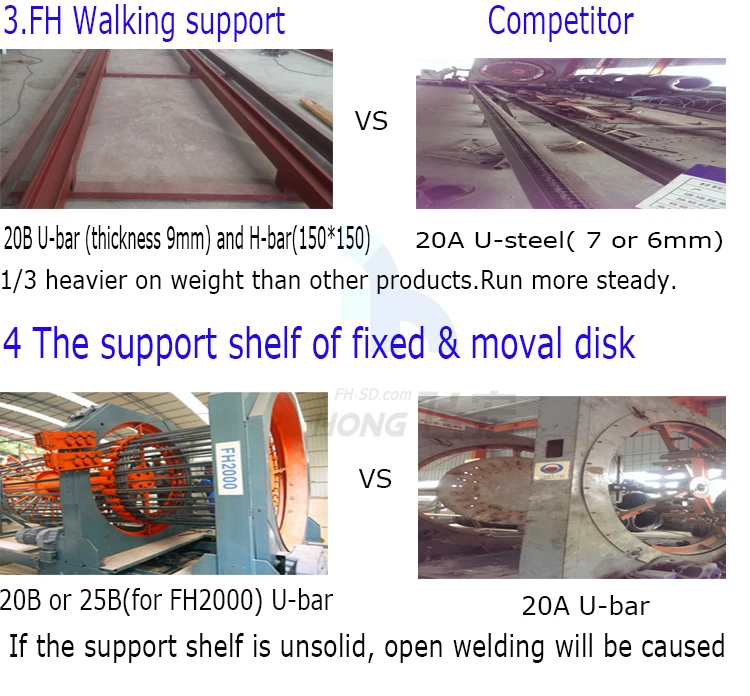

6.The weight of the whole machine is 1/3 more than that of the same kind of equipment in the industry.

7.The hydraulic system is designed specially, adopted the hydraulic component which is in current use in the World, which is durable, and with high interchangeability. With more automatic hydraulic feed rollers, to prevent steel cage deformation due to its own weight.

8.Equipped with automatic feeding device, easy to operate and improve efficiency.

9.Template using the template ring plus U style catheter combination, can be quickly replaced and transform the quantity of main steel cage wire.

10.Outfitted for Accessory Equipment Arc bending Machine and CO2 Shielded Arc Welding.

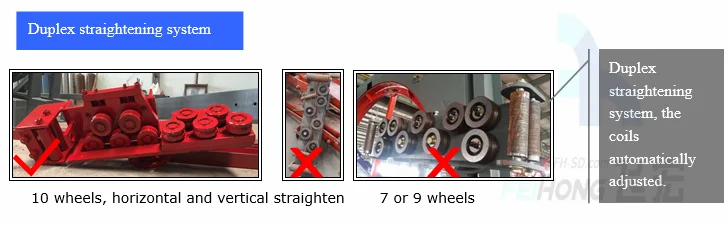

11.Bidirectional straightening arm are made of high strength alloy material, high strength, anti-wear and improve the life of wearing parts, can horizontal/vertical bidirectional adjustment of the coils to ensure the quality of the rebar cage.

Technical Data

|

Product Name |

CNC Steel Bar Pile Cage Maker |

|||

|

Model |

FH1500-12 |

FH2000-12 |

FH2200-12 |

FH2500-12 |

|

Cage pile diameter |

600~1500mm |

800~2000mm |

800~2200mm |

1000~2500mm |

|

Max cage length |

13.5m |

13.5m |

13.5m |

13.5m |

|

Spiral wire diameter |

5.0~16.0mm |

5.0~16.0mm |

5.0~16.0mm |

5.0~16.0mm |

|

Longitudinal bar diameter |

12.0~32.0mm |

12.0~32.0mm |

12.0~32.0mm |

12.0~32.0mm |

|

Spiral pitch |

50~500mm |

50~500mm |

50~500mm |

50~500mm |

|

Mobile disc moving speed |

1100mm/min |

1100mm/min |

1100mm/min |

1100mm/min |

|

Rotary speed |

4r/min |

3.5r/min |

3.5r/min |

3.1r/min |

|

Hydraulic system pressure |

10Mpa |

10Mpa |

10Mpa |

10Mpa |

|

Maximum installed Power supply |

13Kw 380V/50Hz/3Phase |

23Kw 380V/50Hz/3Phase |

23Kw 380V/50Hz/3Phase |

31KW 380V/50Hz/3Phase |

|

Working temperature |

-20°~50℃ |

-20°~50℃ |

-20°~50℃ |

-20°~50℃ |

|

Overall dimension |

28m(L)×5m(W)×2m(H) |

28m(L)×6m(W)×2.5m(H) |

28m(L)×6m(W)×2.5m(H) |

28m(L)×7m(W)×3m(H) |

|

Welding method |

CO2 arc welding (free) |

CO2 arc welding |

CO2 arc welding |

CO2 arc welding |

|

Welding materials |

Welding wire, welding rod (free) |

Welding wire, welding rod |

Welding wire, welding rod |

Welding wire, welding rod |

Detail Image

Packing & Delivery

Packing Details : Cage making machine will be nude packed in container, the parts and tool packed in wooden case.

Delivery Details : 30-40 days after prepayments.

Factory Show

Shandong Feihong Engineering Machinery Co., Ltd,

Shandong Feihong Engineering Machinery Co., Ltd, a leading numerical control steel processing equipment manufacturer, provides practical "automatic numerical control steel processing services program" for the steel processing field and construction site in the fields of highway, high-speed railway and housing construction areas in over 20 countries and regions around the world, so that the global customers have enjoyed "ultra-high quality and professional design" of unique steel automatic processing services.

Our Certifications

Our Service

Pre-sale Service

1. According to your requirements to help you design a reasonable solution,choose a reasonable equipment 2.In-depth explanation of customer service scheme by design experts.

Sale Service

1. Provide the video to help you to learn about how the device works.

2.Help you to know the details of the Key parts and our advantage.

After-sales Service

1. Guarantee for One year.

2. Quality problem, we will send you the accessories.

3. Free repair whole using life (without the freight and accessories charge)

4.24 hours maintenance response: timely feedback within 24 hours after acceptance of maintenance service.

5. Customer can enjoy lifelong value maintenance.

6. Professional and international experienced after-sales service team.

FAQ

1. Q: Are you a factory or trading company?

A: We are a professional manufacturer with strong capability in research, development and manufacturing, you can not only get the factory price but also can enjoy the "ultra-high quality and professional design" unique to Feihong.

2. Q: Where is your factory located? How can I visit there?

A: Our factory is located in Jining City, Shandong Province, China. We have branch Office in Qingdao sea port city, which is very convenient for shipment.All the customers, from home or abroad, are warmly welcome to visit us!

3. Q: Can you do OEM?

A: Yes, we can do OEM as client's requirement.

4.Q: All products have a warranty?

A:YES, Our warranty term is One Year.

5.Q:What about the delivery time?

A:Usually 15-30 days after down payment, the exact delivery time is according to the production season and order quantity.

6. Q: What is the biggest advantage of the company?

A: Stable Better Quality and Perfect Service .

Our company is a state high-tech enterprise, our rebar processing machinery are used in hundreds of infrastructure projects both with China and abroad. We are the framework agreement supplier to CREC(CHINA RAILWAY ENGINEERING CORPORATION).

We have the most complete after-sales service support system ,"8-level quality assurance system," truly lifelong maintenance, customer satisfaction is almost 100%.

Contact Us

| Payment Terms: | L/C,T/T |

|---|---|

Member Information

| Qingdao Dongfeihong Intelligent Technology Co., Ltd | |

|---|---|

| Country/Region: | Shan Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 15066236599 |

| Contact: | Enzo Wang (Marketing Manager) |

| Last Online: | 18 Dec, 2018 |

Related Products of this Company

-

Wire mesh welding machine

US $40000