| Model: | SEB-004 |

|---|---|

| Brand: | XINKAI |

| Origin: | Made In China |

| Category: | Transportation / Car Accessories / Auto Maintenance |

| Label: | die-casting aluminum , battery pack boxes , urban electric muck |

| Price: |

US $35.25

/ pc

|

| Min. Order: | 10 pc |

Product Description

Product Description

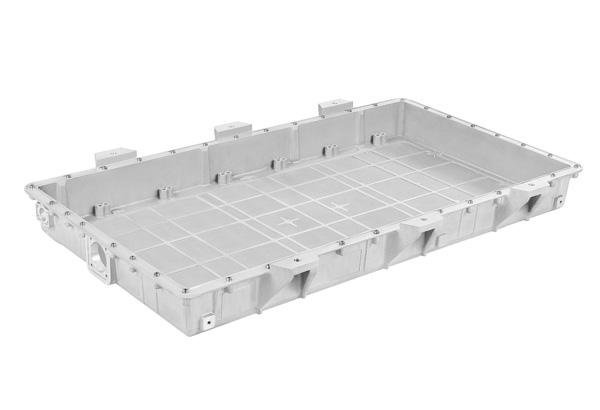

Aluminum battery pack enclosures

Battery box of urban electric muck truck

Length: 935mm width: 712mm height: 170mm

Weight: top cover 20.7kg/bottom cover 23.5kg

Battery pack is the core energy source of new energy vehicle, which provides driving power for the whole vehicle.

As the carrier of the battery module, the battery enclosure plays a key role in the safety and protection of the battery module.Its appearance design mainly from the material, surface corrosion prevention, insulation treatment, product identification and other aspects.

To meet the requirements of strength and stiffness and the design requirements of protection grade IP67 of electrical equipment shell and provide collision protection, the battery module inside the box takes root in the bottom plate, and the wiring harness is reasonable, beautiful and reliable.

1. General requirements

(1) it has the convenience of maintenance.

(2) in case of vehicle collision or spontaneous combustion of battery and other accidents, it is advisable to consider the structure or protective measures to prevent fireworks, liquid and gas from entering the carriage.

(3) the battery box shall be equipped with nameplates and safety signs, leaving enough space and fixed foundation for the installation of insurance, power line, acquisition line and various sensing elements.

(4) all non-polar basic insulated connectors, terminals and electrical contacts shall be strengthened for protection.After connecting parts, terminals and electrical contacts are connected, they should meet the requirements of gb4208-2008 protection grade 3.

2. Appearance and size

(1) there are no obvious scratches, deformation and other defects on the external surface, and the surface coating is uniform.

(2) the parts are fastened reliably and free from rust, burrs, cracks and other defects and damages.

3. Mechanical strength

(1) vibration resistance and impact resistance. After the test, there should be no mechanical damage, deformation or loosening of the fastening parts, and the locking device should not be damaged.

(2) the battery box fixed by the locking device shall be adopted. The locking device shall be reliable with anti-misoperation measures.

4. Safety requirements

(1) after the test, the protection level of the battery box shall not be lower than IP55.

(2) electric shock protection of personnel shall meet relevant requirements.

After completing the design of the whole power battery system, the completed power battery system must pass the bench performance test to verify whether it meets the design requirements.

Our Company

The factory covers an area of 26,700 square meters, with 39 series of products and nearly 3,000 varieties. About 500 sets of plastic molds and aluminum die casting molds are manufactured every year, with an annual output of 500,000 cases and shells.The company's largest aluminum die-casting machine is 1250 tons, the largest injection molding machine is 6300 grams, the largest stamping machine is 100 tons, the largest processing center area is 1500*1200, various processing equipment such as CNC puncher, bending machine, drilling and milling integrated machine and laser cutting equipment 120, the production capacity is up to 15 million USD.The company has a perfect quality assurance system, processing quality to reach the international advanced level, welcome customers from all over the world to cooperate or OEM.My company has mitsubishi slow line cutting machine, spark machine, Taiwan peak processing center, engraving and milling machine, surface grinding machine and other dozens of precision mold equipment.The aluminum die-casting workshop is equipped with Hong Kong die-casting machines of 160 tons, 350 tons, 600 tons and 1,250 tons.The injection molding workshop is equipped with nearly 30 sets of plastic injection molding machines, with a maximum injection molding capacity of 6300g.In addition, there are CNC puncher, bending machine, drilling and milling and precision cutting equipment 120.Recently the company has imported three sets of Japanese painting equipment.Sophisticated equipment for the development of high-precision mold and high-grade products will provide a strong guarantee.

Our Service

1.Your inquiry related to our products or prices will be replied in 12 hours.

2.Individual formula according to customers' special drawing requests

3.Manufacturer with large capacity,ensures the fast production cycle after confirming the order.

4.Protection of sales area and private information for all of our customers.

5. Providing free samples + dimension inspection report + material report;

6. Checking raw material, and inform customer before mass production;

7. Informing customer production schedule weekly;

8. Arrange shipment, and Inform customer in advance 7 days before finishing the order;

9. Before shipment, send the detailed product pictures, dimension inspection report, material report to customer;

10.Delivery is on time.

Member Information

| T aiyuan SIMIS Precision Casting Co.,LTD | |

|---|---|

| Country/Region: | Shan Xi - China |

| Business Nature: | Manufacturer |

| Phone: | 13934165890 |

| Contact: | Felix Fan (project manager) |

| Last Online: | 29 Nov, 2018 |