Patent NO.:ZL201410096002.5

Model:KS-MAM-0350

1. Feeding Unit: one operator makes manual sheets feeding

2. Transfer Unit: applying the servo transfer, roll ball lead ways, make the location accurately, less than 0.2mm.

3. Magstripe Transfer Unit: parallel design, magstripe material feeding position easily, adjust easily and fast.

4. Lamination Unit: applying heat tube and thermal detector to ensure the lamination OK rate reaches 99.99%.

5. Output Unit: apply the gravity and oblique drop to make the sheet output tidily. It could store 600 sheets (could be customized).

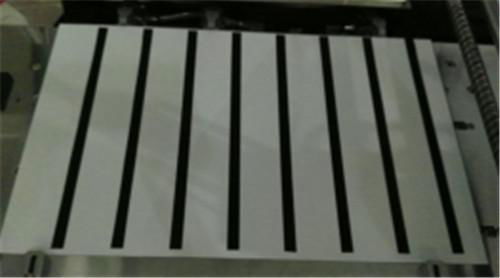

6. The sheet thickness is 0.25 - 0.8mm, the working temperature is 0-400°C. The magnetic stripe max numbers is 8. It could work for different layouts.

This machine applies the PLC control, it could be used for different kinds of magstripes placing on the sheet. The sheet material could be PVC, PE, ABS, PC, TeColas and so on. It could also work for separated stripes and non-separated stripes.