| Model: | CGN |

|---|---|

| Brand: | HAOPAK |

| Origin: | Made In China |

| Category: | Industrial Supplies / Food, Beverage & Cereal Machine |

| Label: | water machine , soda machine , mineral water fillin |

| Price: |

US $30000

/ pc

|

| Min. Order: | 1 pc |

Product Description

General Description

This washing-filling-capping integrate machine, 3-in-1 monoblock is designed and produced by our company. It has stable performance, advanced technology, beautiful appearance, and full function.

The machine is mainly used for PET bottle water washing-filling-capping.

1. Adopt food grade SUS304 stainless steel material, compact structure, reasonable design, small footprint, production capacity from 2000-36000b/h all can be customized;

2. PLC control, touch screen human-computer interaction interface, easy to operate, easy to maintain; The whole line output can be adjusted and has good compatibility and expansibility.

3. Perfect to meet customer needs, has small investment, quick results! It is small and medium-sized bottled water manufacturers ideal production and processing equipment!

It adopts technology of air conveyor direct connect with bottle infeed starwheel to instead of screw and conveyor. It is easier and more simple to change over bottle size. Adopt neck handling technology to convey bottles. There is no need to adjust the height of equipment and only need to change some spare parts.

By 3-in-1 monoblock, the bottle goes through washing, filling and capping with little abrasion, and the transferring is stable, bottle changing is easier. Specially designed stainless steel bottle gripper dose not contact the thread parts of the bottle neck, avoiding the second contamination. High speed and mass flow filling valve ensures the high filling speed and exact fluid level. parts contacting liquid are all made of excellent stainless steel or food grade engineering plastic. the electric system is from international brand and achieves the national food hygienic standard. the bottle-out starwheel is helical structure. while changing over bottle size. It is no need to adjust bottle-out conveyor height.

| Technical parameters | 18-18-6 | 24-24-8 | 32-32-10 | 40-40-12 | 50-50-15 | 60-60-15 | 72-72-18 | 80-80-20 |

| Production capacity (500ml)(B/H) | 6000 | 10000 | 14000 | 18000 | 24000 | 30000 | 35000 | 40000 |

| Bottle washing station | 2.5 | 5 | 6 | 8 | 11 | 15 | 20 | 20 |

| Drying station | 3.5 | 6 | 10 | 12 | 14 | 25 | 27 | 32 |

| PET bottle size (mm) | D=60~97mm | |||||||

| H=150~320mm | ||||||||

| Capping torque (N.m) | 0.6~2.8 | 0.6~2.8 | 0.6~2.8 | 0.6~2.8 | 0.6~2.8 | 0.6~2.8 | 0.6~2.8 | 0.6~2.8 |

| Installed capacity (Kw) | 2.38 | 4.18 | 4.18 | 4.37 | 5.87 | 5.87 | 9.57 | 9.57 |

| Compressed Air consumption(0.6Mpa)Nm3/min | 0.5 | 0.6 | 0.8 | 0.8 | 1 | 1.5 | 1.5 | 2 |

| Washing bottles water consumption(0.2-0.25Mpa)m3/h | 1.5 | 1.5~2 | 1.5~2 | 1.5~2 | 2~2.5 | 2~2.5 | 2.5~3 | 2.5~3 |

| Dimension(L*W*H)(mm) | 2500×2000×2850 | 2800×2300×2850 | 4150×2560×2850 | 4400×2800×2850 | 5350×3400×2850 | 5520×4750×2850 | 7100×6250×2850 | 7700×6750×2850 |

| Weight(t) | 4.5 | 6 | 7 | 8 | 9.5 | 13 | 15 |

16 |

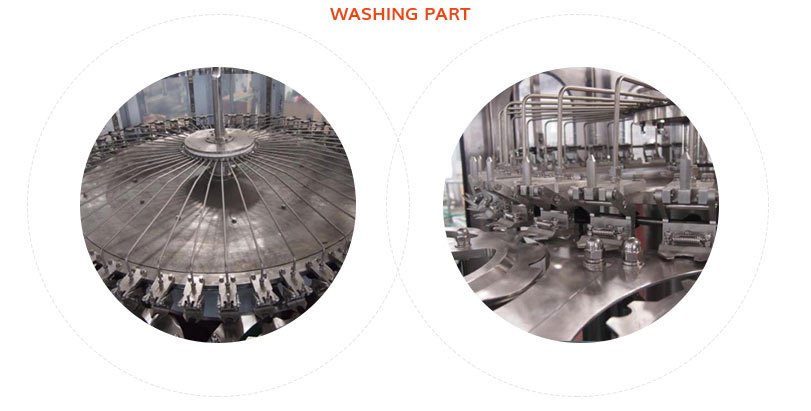

The overall structure integration

The overall structure integration

The 3-in-1 unit completed the three processes of washing bottle, filling and sealing.

stainsteel tube, bottle washing clamp isometric design.< a little abrasion >

Specially designed stainless steel bottle gripper does not contact the thread parts of the bottle neck,avoiding the second contamination.

bottle washing clamp isometric design. Not need exchange parts can work with 0.3-2L bottles.

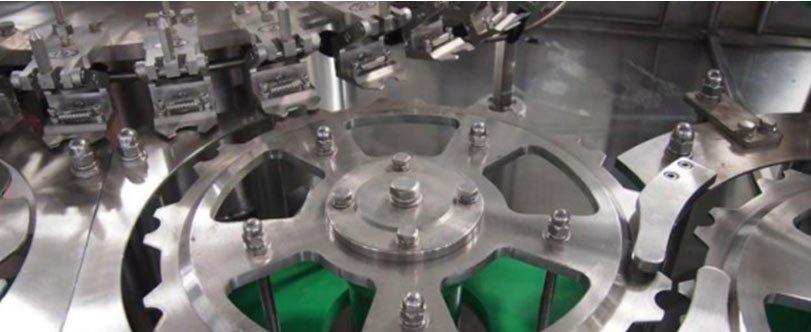

bottle-out Starwheel < the transferring is stable >

bottle-out Starwheel < the transferring is stable >

Adopt neck handing technology to convey bottles.there is no need to adjust the height of equipment and only need to change some spare parts.

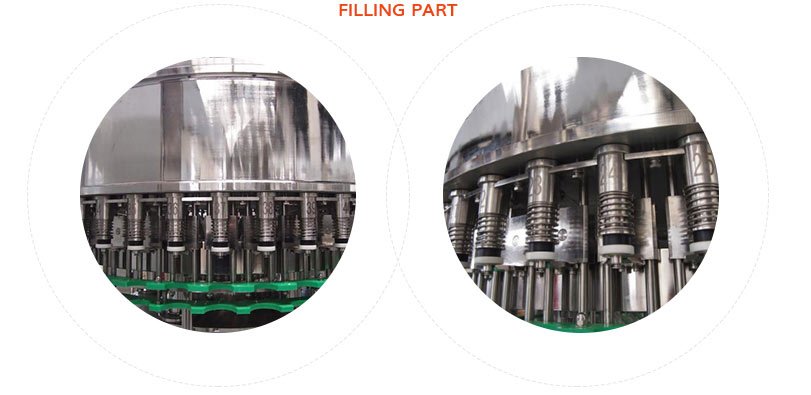

Filling valve < high filling and exact fluid level >

Filling valve < high filling and exact fluid level >

High speed and mass flow filling valve ensures the high filling speed and exact fluid level. Parts contacting liquid are all made of excellent stainless steel or food grade engineering plastic. filling valves, machine scutcheon etc. use laser printing.

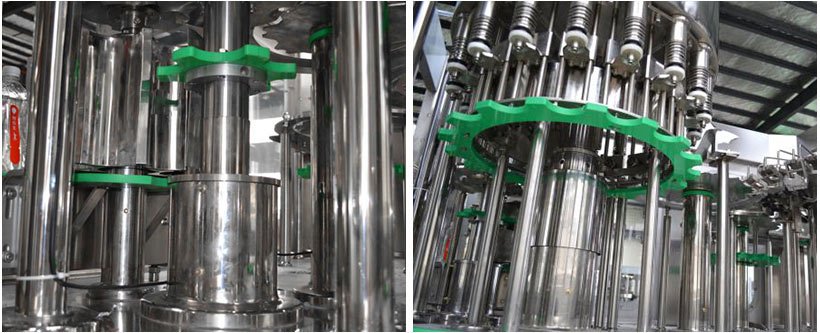

Gland device < bottle change is easier >

Gland device < bottle change is easier >

capping head have itself scale. Easier adjust and count.

| Payment Terms: | L/C T/T Western Union |

|---|---|

Member Information

| Zhangjiagang Hao Pak Machinery Co.,Ltd | |

|---|---|

| Country/Region: | Jiang Su - China |

| Business Nature: | Manufacturer |

| Phone: | 15862622744 |

| Contact: | Jack (Director) |

| Last Online: | 15 Jan, 2019 |

Related Products of this Company

-

Automatic Can Aluminum Bottle Drink

US $56000

-

Pet Bottle Carbonated Drink

US $56000