| Model: | D-stream 15030 |

|---|---|

| Brand: | Watex |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Cleaning Machine |

| Label: | water jetting , water blaster , water jetter machine |

| Price: |

-

|

| Min. Order: | 1 pc |

Product Description

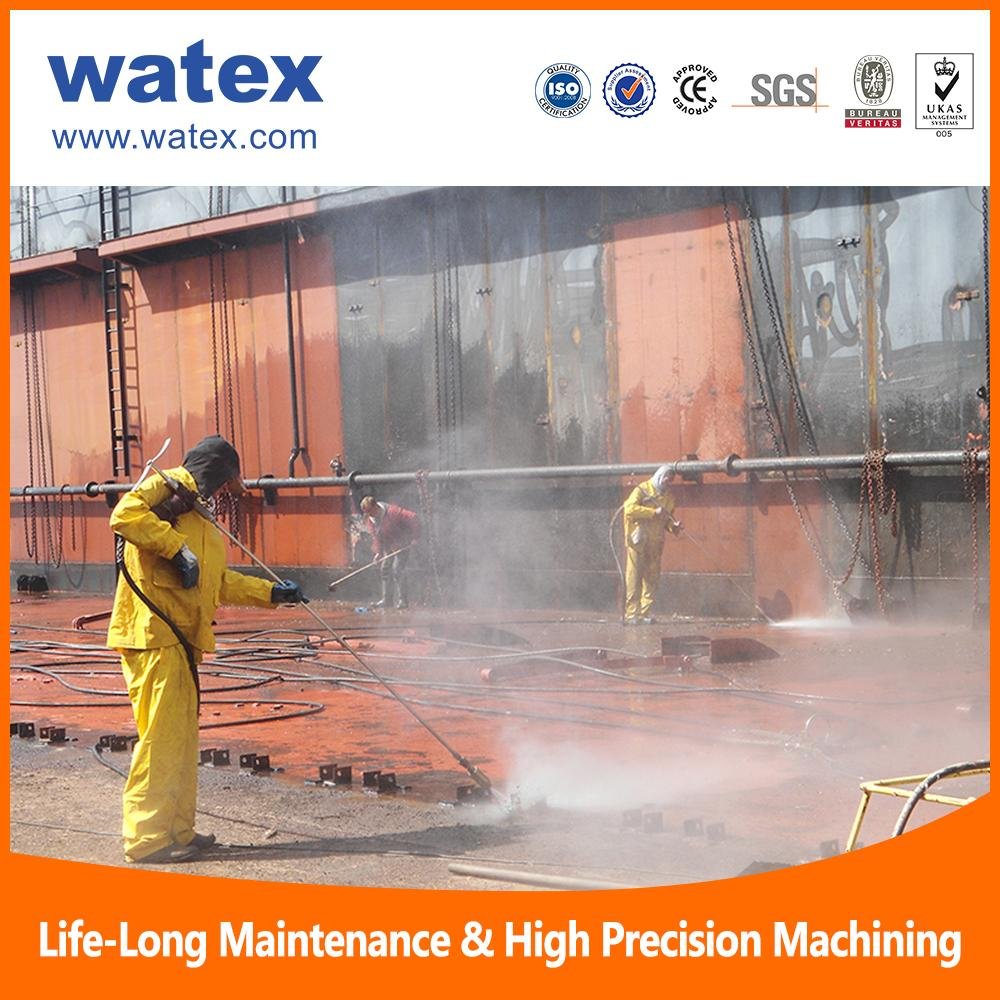

Product Application

High pressure water jetting machine

D-stream high pressure water jetting machine is fitted with heavy-duty triple ceramic plunger pumps, unload valves and safety burst discs or safety valves. The electric motors are heavy duty, low revising which results in less wear to the pump and lower maintenance costs. Pressure is fully adjustable, and chemical injectors are fitted to all units.

Watex D-stream units are designed for maximum reliability and simplicity, resulting in lower maintenance costs, less downtime, and greater productivity. Our diesel water washer units are available in a wide selection of standard models and options.

For water blasting applications within process plants, industrial operations and military environments, electric water blasters are available as stationary skids or steerable in-plant trailers with input power from 60 to 250 hp (45 to 186 kW) at working pressures from 5,000 to 40,000 psi (350 to 2750 bar).

This innovative line of high pressure water jetting units are designed around the model E-stream pump. This pump, with its quick-change, in-line fluid end design, has fewer parts for increased operating efficiency and simpler maintenance. And, it requires only a simple conversion kit to operate at pressures between 6,000 and 40,000 psi (414 and 2,800 bar) with flows to 32 gpm (122 lpm).

The D-Stream Series water jetting units have been designed to tackle the toughest water jet machine applications. Their quick-change, in-line fluid end design has fewer parts for increased operating efficiency and simpler maintenance. The units are built around a slow running triplex plunger pump to minimize wear and maintenance, saving money on parts and increasing up time

Main Features

Key Benefits

• A commanding 600HP Cummins 13.5L engine with a bypass filtration system that extends drain interval maintenance.

• Triple 200 gpm filtration allowing bag changes while the unit is running.

• A 250 stainles water tank extends the longevity of the parts by allowing the water to de-aerate before entering the pump.

• The compact design is the smallest in the industry for a 600HP waterblaster.

Fluid Ends

• In-Line Univalve Cartridge

• Swing-Down manifold for full component access

• Convert to various pressures in the field with minimal downtime

• Unique to the 600HP: Engine driven charge pump to ensure the fluid end receives water at the correct pressure, regardless of the supply conditions.

Stainless Fuel Tank

• 300 gallon tank with internal baffles

• No rust contamination

• Removable for easy cleaning

Stainless Water Tank

• 250 gallon water tank

• Allows for water to de-aerate before entering the pump, extending the life of the parts.

• Triple 200 gpm filters - the first in its class!

• Low water level switch to prevent cavitation from water supply problems

D-stream high pressure water washer

| Model | D-430 | D-530 | D-630 | D-730 |

| Drive system | Diesel | Diesel | Diesel | Diesel |

| Pressure system | Three plunger pump | Three plunger pump | Three plunger pump | Three plunger pump |

| Amount of pressure system | 1 | 1 | 1 | 1 |

| Max outlet pressure | 300MPA | 300MPA | 300MPA | 300MPA |

| Max flow rate | 14.8L/min | 24L/min | 70L/min | 120L/min |

| Power | 75W/100HP | 120W/150HP | 160W/210HP | 225W/300HP |

| Amount of total gun | 1 | 1 | 1 | 1 |

|

Configuration: 1. Ultra high-pressure pump

|

Details:

1. High pressure triple plunger pump ( Reciprocating plunger pump, Easy maintenance pump head )

Pressure: 500bar to 1500bar

Water flow: 40 LPM to 80 LPM

2. Engine: diesel engine or Electric motor drive. customer can choose the one they prefer

For diesel engine: Brand has two: WeiChai and Cummis

For electric motor, Brand is SIEMENS or HUALE

3. Pressure regulating valve: 0~ 1500bar. easy to be adjustable.

4. Safety valve: High pressure Rupture Disc valve

5. Self Aligning, Water Cooled, Tungsten Coated Plungers,

6. Water tank: stainless steel material, 300L

7. Oil tank: ( for diesel engine) stainless steel material 200L

8. High pressure dump gun: Max. pressure 1500bar. stainless steel material.easy to be control and operate.

9. High pressure hose: 6 layer of steel wire . Length can be meet customer's request.

10 High pressure nozzle: single-hole self rotating nozzle, fan-shaped nozzle ( flat nozzle), Cylindrical type nozzle

11.Warranty: One Year

12.Spare Parts: One year spare parts for use.

FAQ

Q: How do I pay for my purchase order?

T/T, L/C at sight, Paypal, Westunion

Q: How can I get sample and how long will it takes?

Testing will free small parts will be free,big parts need extra fees, but we will refund the extra money after you place an order to us It usually takes 15-25 days to produce a sample.

Q: What's about MOQ?

Our MOQ is one set.

Q: What's the delivery time in your factory ?

It will take about 45 days to finish an order. But the exact time is according to actual situation.

Q: Can I have my own customized product?

Yes, We have OEM service, your customized requirements for color, logo, design, package, carton mark, etc. are very

welcome.

Q: Do you have quality control ?

Yes, we have R&D center and inspection and quality departmenet.

Q: How about the warranty ?

One year warranty; supply service forever.

Q: What is the working principle of your pump?

Our high-pressure plunger pump adopt the high pressure water jet flow to remove dirt, grease and rust paint without toxic

Q: What is your driven system ?

Electric, diesel engine.

Q: What kind of pump do you have in your company ?

As long as you provide us with your role object, the flow and pressure. We can recommend to you.

Q: Are you manufacture or trading company ?

We are manuafacture in the industry of high pressure water more than 20 years

| Price Terms: | FOB nanjing |

|---|---|

| Payment Terms: | 30% as deposit ,70% pay before delivery |

| Packing: | steel frame |

| Lead Time: | 30 days |

| Standards Certificate: | CE ,TUV ,ISO 9001:2008 |

Member Information

| Watex Waterjet Co.,Ltd | |

|---|---|

| Country/Region: | Jiang Su - China |

| Business Nature: | Manufacturer |

| Phone: | 5861660 |

| Contact: | Arron (sales manager) |

| Last Online: | 03 Jun, 2024 |