| Model: | q2603 |

|---|---|

| Brand: | XINSA |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Cleaning Machine |

| Label: | blasting chamber , Cycling chamber , recovery system |

| Price: |

US $45000

/ pc

|

| Min. Order: | 1 pc |

Product Description

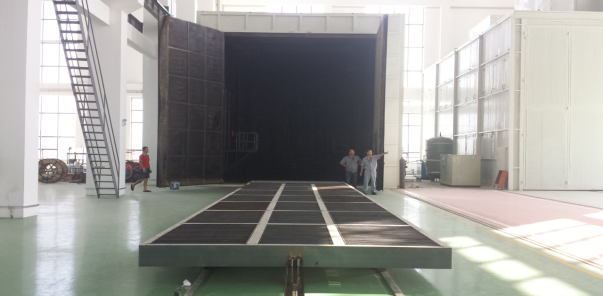

Our company independently designs this kind of honeycomb floor plate pellet circulating purification system.

The bottom of the sandblasting chamber is the area where sand is collected and the dust pipe is arranged, which is specially used to collect the abrasives scattered during sand blasting and dust produced during sand blasting. In this scheme, the shape of "v" is made of steel plate in sand collection area, which is beneficial to the recovery and capture of abrasives and dust.

The combination of the sand room module and the detachable honeycomb floor is based on the original honeycomb floor technology, and through the optimization and improvement of a plurality of times, the abrasion and the maintenance of the honeycomb recovery floor and the recovery pipeline during the long-term use are fully considered, The recycled floor and the recovery pipeline are made into a detachable modular combination mode. The maintenance work of the equipment is extremely simple and quick, a large number of accessory replacement is saved, and the maintenance cost of the equipment during the long-term use process is reduced. This structure is the first of our company and successfully applied to the environment-friendly pneumatic recovery sand-blasting house body project of many customers. The blasting chamber of this type only needs to make the depth of the deep trench to be less than 0.35m.

The bottom of the honeycomb floor is evenly covered with honeycomb-type buckets, which are connected with the gas separation pipeline under the small bucket, and the wind speed of the gas separation pipe and the main gas pipeline is greater than the suspended velocity of the sand material; During the sand blasting operation, all the sand ejected fell into the honeycomb type small bucket, then fell into the distributor pipe from the small bucket, and finally returned to the sand dust separator through the main gas line.

XINSA honeycomb recycled floor has a relatively quick and simple maintenance method, first of all, honeycomb floor structure is simple, easy to wear parts, need to maintain parts and less; And the honeycomb floor adopts the modular combination mode, can easily disassemble each part, enters to the inspection point. Then the honeycomb floor made the parts such as easily worn bends into "standard parts", that is to say, they were made standard replacement fittings, connected with flanged joints, as long as the connecting bucket plates were opened when replaced, and the worn parts were removed and replaced with new parts by loosening the joint flanges. There is no need for on-the-spot soldering and cutting. It greatly facilitates daily maintenance.

A layer of punched steel plate is laid on the top of the honeycomb floor as the ground, the operator stands directly on the ground, and the punched steel plate floor adopts riveting structure. Compared with the grille floor previously used, it prevents the phenomenon of "shaking" and is more stable and reliable. At the same time increased the protection of honeycomb floor.

| Serial number | Contrast item |

Honeycomb air cycle sand blasting chamber

|

Traditional mechanical cycle sand blasting room

|

| 1 | grain material cycle mode | Pneumatic tube transport | screw conveyor,belt machine,buchet elevator, scraper etc. |

| 2 | maintenance |

maintenance-free,maintenance convenience |

Mechanical moving parts operate in harsh sand and dust environment with high failure rate and inconvenient maintenance. |

| 3 | infrastructure |

Low or no cost. |

Foundation construction cost about $6000~$9000 |

| 4 | grain sorted |

The grain-size sorting of abrasive can realize stepless adjustment in a certain range.

|

The separation diameter of abrasive can not be adjusted |

| 5 | layout |

Beautiful, small area, easy to install, due to all equipment pipe connection, the system can be installed according to the location of the scene.

|

Each transmission system needs close cooperation, unable to change the installation position, occupies large area, and is not easy to maintain |

| 6 | Occupational Safety and Environmental Protection

|

Overall dust absorption floor, wind flow from top to bottom, dust suppression environment, dust content, visibility, dust emissions are better than the national standards

|

Due to the installation of sand conveying equipment underground, the air suction mode is usually updraft or sideways suction |

we also can design and manufacture all kind of non-standard Pneumatic sand blasting room with automatic abrasive recovery system according to customer's different workpiece detail requirement,weight and productivity.

Notice:

According to your requirements, the most suitable machine will be designed for your workpieces, please indicate the following details.

1. What kind of workpiece you clean?

2. The workpiece size, length, width, height and weight of maximum workpiece.

3. What's your production capacity per day (8 hours)?

4. It's my pleasure if you can provide details workpiece photos to us.

Based on these details information, the detailed technical proposals will be sent to you for reference.

FAQ:

After-sale service:

1. Installation and commissioning issue: We will send one technicians to assist with machine installation and commissioning, customer pays for return tickets, hotel and diet. Customer need arrange skilled worker and prepare various installation machinery and tools.

2. Warranty time:12 months from date of commissioning completion, but no more than 18 months from date of delivery.

3. Supply full english documents: including general installation drawings, pit design drawings, manual book, electric wiring diagram, electric manual book and maintenance book, etc.

4. Exported experience : Many countries, such as The USA, Russia, UK, Ukraine, Australia, Malaysia, UAE, Egypt, Mexico, Brasil, etc.

5. Our shot blasting spare parts are high quality with Cr20S High Chrome, ZGMn13, Mn65, etc.

Trade Information:

MOQ: 1set.

Settlement Currency: USD, RMB, EUR.

Trade mode: FOB (FCA), CIP, CFR, CIF, DDU, DDP, Turnkey.

Payment term: 30% deposit by T/T, the balance paid before delivery or L/C at sight.

Delivery time: Within 20-60 days according to different type equipment.

Any question pls kindly contact with us and welcome to visit our factory!

Contact: alina

Tel:+86-532-84126287

Cell: +86 18563913196

Wechat:18563913196

Skype:18563913196

Email:xinsafu@126.com

http://www.chinaxinsa.com/

Member Information

| qingdao xinsa machinery manufacturing Co., Ltd | |

|---|---|

| Country/Region: | Shan Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 18563913196 |

| Contact: | alina (sales manager) |

| Last Online: | 27 Feb, 2019 |

Related Products of this Company

-

hanger hook type shot blast cleaning

US $9358

-

Steel pipe shotblasting machine for

US $34328

-

Through shot blasting machine china

US $38806

-

Mobile portable shot blasting machine

US $16418

-

Crawler shot blasting machine from china

US $5800

-

Trolley type air sand blasting chamber

US $18000

-

Sand blasting chamber with pneumatic

US $44776

-

Steel deck shot blasting machine use in

US $13432

-

mesh belt shot blast cleaning machine

US $11650

-

Steel plate shot blasting machine from

US $15100