The machine tool is a three-function composite machine tool. Diamond cutting uses the reciprocating motion of the sand line to cut the sand line and the workpiece to achieve the purpose of processing. Therefore, it is necessary to use a special electroplating diamond wire(abbreviated as sand WIRE) as a tool to process the workpiece. The workpiece automatically moves according to the trajectory determined by the program under the control of a numerical control device or a computer, and finally gets the workpiece of the desired shape.

The U-shaft arm of the machine tool is arranged on a fractional rotating table, and the U-shaft drive part controls the lifting of the U-shaft arm. The rotating table is fixed and installed with a precision spindle grinding head. The rotating table can adjust and set the precision grinding head processing angle, and precision grinding can be performed. Or precision angle inversion.

The V-axis drive part controls the motion of the V-axis rotation table, the V-axis rotation table is placed on the workpiece bridge board, and the V-axis drive controls the fractional rotation of the V-axis rotation table.

1, model description such as CHSX5640-TT 800 X400:

CH Taizhou Chenhong Digital Control Equipment Manufacturing Co., Ltd.. Trademark "Chenhong" Trademark Chinese Pinyin abbreviation

SX(`` Sand Line "two Chinese Pinyin initials)

56(National Standard Machine Tool Classification Code)

40(x axis stroke 400 mm)

2, workbench size: 920 × 420mm

3, workbench left and right stroke(X axis): 800 mm

4, work table before and after the trip(Y axis): 400 mm

5, workbench T-slot number: 2

6, number of workpieces: 2

7, additional bridge frame number: 2

8, the highest productivity(graphite, precision and finish) ≥ 600 mm <UNK> / min

9, handwheel per wheel table movement of 4mm, handwheel per table movement of 0.001, 0.01, 0.1 mm.

10, sand line selected 0.5, 1.0, 1.5, 2.0 mm in diameter.

11, Pulse equivalent: workbench 0.001 mm.

The fine fraction of the V-axis drive is set to 3200, the speed of the V-axis CNC axis table is 1:10, and the controller sets the V-axis movement distance of 32mm to turn 360 degrees. Rotation table angle θ = 360 * V shift / 32 or V shift = θ * 32/360

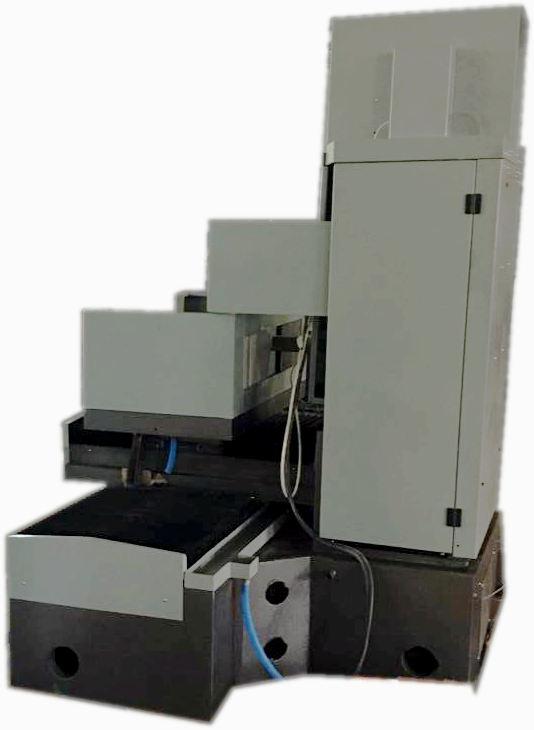

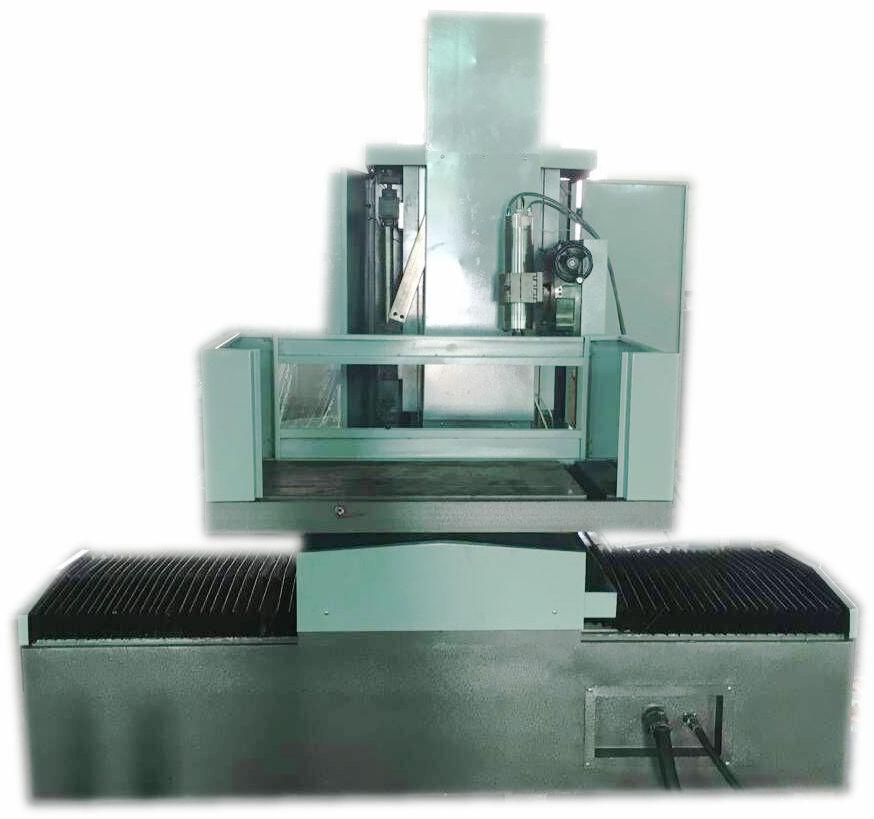

Main Structure and Working Principle of Machine Tool

The machine tool is controlled by a digital program to process various complex workpieces composed of straight lines and garden arcs. When diamond wire is cut, the diamond wire is reciprocated by the bow frame, cutting with the workpiece to achieve the purpose of processing.

The grinding plate rotates under the drive of the precision grinding spindle, cuts with the workpiece, and the scale plate can adjust the working angle of the grinding spindle, so that the corner grinding can be carried out. The V-axis rotating table can perform fractional rotation to enhance the process, and the V-axis rotating table can be easily unloaded(the V-axis motor drive power supply is a detachable interface).

The machine tool consists of a bed body, coordinate worktable, bow frame, working liquid box and accessories. The sand wire is fixed on the bow frame for processing. The workpiece is fixed with a plate screw. The console emits a pulse signal, controls the drive amplifier, drives the stepper motor to rotate according to the signal, controls the workpiece motion to cut the workpiece, and processes straight lines and arcs. And other geometric figures.

1, bed:

It is a box-shaped casting. It is equipped with a worktable, a bow frame, an internal motor for the vertical column, and a water tank around it. It has a good steely nature and is the basis for ensuring the accuracy of the machine tool.

2, the workbench components are mainly composed of a work table, a lower drag plate, a precision ball screw and a variable speed gearbox. The vertical and horizontal motion of the towing plate is achieved by using a precise linear guide rail structure, which is carried out by a fine step motor and a ball screw drive. Because the control system adopts open-loop control, the precision of the table motion will directly affect the machining precision.

The front end of the ball screw adopts two thrust ball bearings to eliminate axial clearance, and can adjust the pre-tightening force to make the gap close to zero. It has the advantages of light and flexible transmission, high accuracy, and long life.

3, bow frame

The bow frame is made of stainless steel. The motor is given to the bow frame by means of a triangular belt and then by eccentric wheel transmission, so that the sand wire used for processing has 700

The speed of the time / minute is processed.

Horizontal arm foreend device component, precision grinding spindle component fixed on the head of the component, the spindle can be infinitely adjusted.

U-shaft drive lateral arm lift can adjust the working height of the spindle.

CNC V shaft rotating table parts, can be removed Square.

6, working liquid tank:

The water pump sends the working fluid to the processing area, soils and accumulates in the dirty box, and regularly cleans up. In order to ensure the processing efficiency, the working fluid needs to be replaced regularly.

7, annex:

Fixture: It consists of two plates, the middle is connected with a rigid body to form a special cutting fixture, the workpiece is placed on the upper surface of the fixture, and is secured with a plate screw.

III. Points to Note on the Use of this Machine Tool

1(1) The danger of impact on the operator may occur due to the high-speed reciprocating movement of the bow frame during processing. Therefore, do not touch the bow frame during processing.

(2) Calculate the coordinate point preparation procedure according to the size of the drawing and the actual conditions of the workpiece. However, we should consider the method of loading the workpiece and the diameter of the sand line, and choose a reasonable cutting site.

(3) Proofreading their graphics with a physical display, as programmed. The more complex shape of the workpiece, it is best to operate the console, so that the machine tool is empty once, first cut the thin sheet specimen, and proofread the program compiled one by one.

(4) Pay attention to the position when loading the workpiece so that the machining cavity can be within the range of the worktable movement. For workpieces with small machining margins or special requirements, the workpiece must be accurately adjusted for vertical and horizontal movement of the workpiece and the worktable, so as to avoid scrapping the workpiece without sufficient margin, and write down the vertical and horizontal coordinates of the workpiece.

(5) When processing concave plates and certain special cavities, sand lines should first be penetrated into the pre-drilling of the workpiece.

Check the tensioning of the sand thread.

(7) After the processing is completed, first press the sand wire to turn off the switch, and then turn off the pump. The wooden machine tool has an end shutdown function and the machine tool will automatically shut down.

2(1) According to the processing grinding requirements, the spindle is raised and lowered to a suitable position.

Special attention: U-shaft drive motor with lock, U-shaft drive operation, first open the U-shaft lock switch! After running, close the lock switch.

The main factors affecting the machining precision of diamond wire cutter and the concrete measures to improve the machining precision

In the process, besides the motion precision of the machine tool directly affects the machining precision, the change of the machining gap caused by the deformation of the workpiece and the wear of the sand wire also has a significant impact on the machining accuracy.

Machine tool accuracy: The inspection project of machine tool accuracy at the factory time has been guaranteed, but before processing the precision workpiece, the user must make adjustments to the necessary precision test of the machine tool.

(1) Check whether the fastening nut of the work table wire rod bearing is loose, and if it is loosed, lock it in a timely manner.

(2) Inspection of longitudinal and horizontal trawler gap: The coordination gap of vertical and horizontal trawler gap, due to frequent reciprocating motion changes, so in the processing of precision workpieces, must carefully check and adjust, wait to meet the corresponding standards before starting processing.

2, the size of the sand line tension is closely related to the material, cutting speed, cooling liquid composition.

(1) Sand line tension size: different tension sizes due to the processing of different materials and different thickness of the same material. That is, different mechanical properties and workpiece thickness are different in processing and affect the machining accuracy.

(2) The relationship between the wear degree of sand wire and the cutting speed: cutting speed in an effective processing range, bending and deformation of sand wire, and poor cutting accuracy; The cutting speed is slow, the sand line bending deformation is small, and the cutting precision is good. Maintain proper processing speed during cutting process,

It is very important for machining accuracy. In order to improve the machining precision, we should make every effort to adjust in time.

(3) The relationship between processing quality and coolant: the different components of the coolant and its duckling ability affect surface quality,

Therefore, when processing high-precision workpieces, must be reasonable adjustment according to requirements.

Machine Tool Transmission System

1, sand line

Motor-small pulley-pulley-large pulley-eccentric pulley-connecting rod-bow frame-sand wire.

2, grinding head U-axis drive lift

Disc-Spindle-Grinding wheel U-axis motor-Ball screw rod-cross arm lift

3, workbench

86 Hybrid stepping motor-ball screw-worktable(same vertical and horizontal system)

Machine Tool Control System

Serial name is used

(1) Operation table panel realizes the work of machine tool electrical appliances

(2) Water pumps regulate the flow of working fluids in water sprays