| Model: | all sizes |

|---|---|

| Brand: | GW |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machine Hardware / Other Machine Hardware |

| Label: | Spray Nozzle , carbide nozzle , Boron Carbide Nozzle |

| Price: |

US $6.8

/ pc

|

| Min. Order: | 5 pc |

Product Description

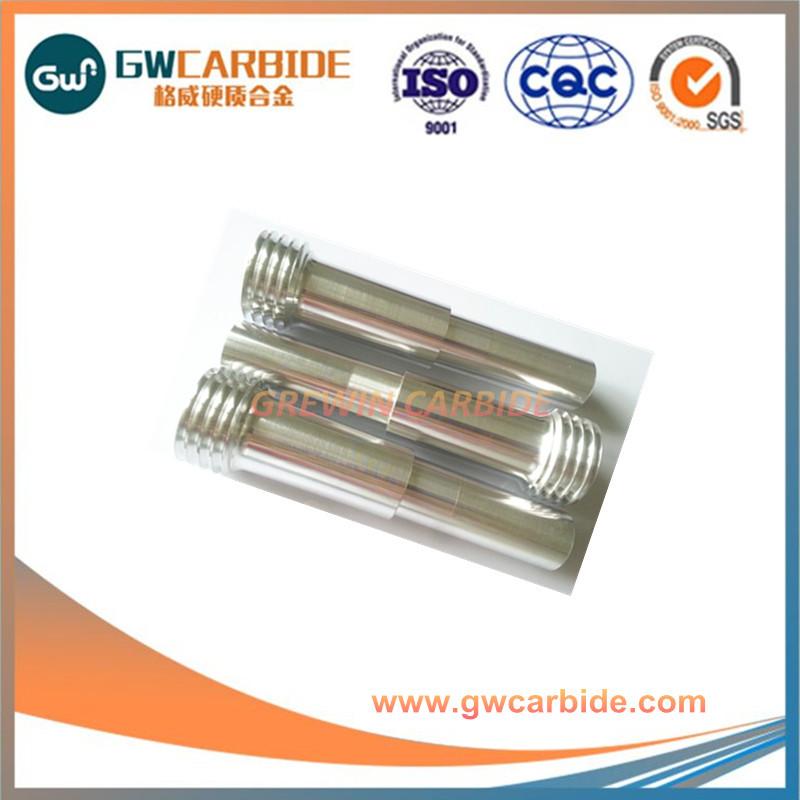

1. Boron carbide sand blasting nozzles

they have a service life 4-7times of sintered tungsten carbide nozzles, but their shock resistance is not as that of sintered carbide nozzles, so are suitable to serve under wear, stable atmospheric pressure and medium shock.

Specification:

Grind resistant, do not active with acid, low & high temperature resistance,

The density> =2.46g/cm3;

Hardness> =3500kgf/sqm, bending resistance: ≥ 400Mpa

Melting point: 2450degree

And now boron carbide nozzle is instead of hardness alloy, Tungsten carbide nozzle, silicon carbide sandblasting nozzle.

The working life of boron carbide nozzle is 500-1000H

The size can be customized as per drawing

2. Sintered tungsten carbide nozzles

products including various sand blasting nozzle, high-pressure water spray nozzle, high-pressure water cutting nozzle, bars, sheets, sealing rings, punching die blocks, glass cutters, etc.

We are able to produce tubes with diameter of 200mm and length of 300mm, for rings, size can be diameter up to 320mm and length to be 200mm.

advantages on Tungsten carbide sand blasting nozzles :

1. very high hardness.

2. stable working effort during blasting.

3. long sizes are accetable.

4. very good prices with quite fast delivery.

5. special sizes with drawing are acceptable.

Grade Recommend of Tungsten carbide sand blasting nozzles :

| Grade | Equal to ISO Category Number | Performance | Uses | ||

| Density | Bend Strength | Hardness | |||

| G/Cm3 | N/mm2 | HRA | |||

| YG3 | K01 | 14.9-15.3 | 1180 | ≥90.5 | sand-blasting nozzlesQualified for fine turning and half-fine turning when cast iron, non-ferrous metal, alloys as well as non-alloy materials cutting consecutively. Can make wire drawing of steel and non-ferrous metal. Also qualified for sand-blasting nozzles. |

| YG3X | K01 | 15.1-15.4 | ≥1300 | ≥91.5 | |

| YG6X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | Qualified for machining of chilled cast iron, alloy cast iron, refractory steel and alloy steel. Also Qualified for the machining of common cast iron. |

| YG6A | K10 | 14.7-15.1 | ≥1580 | ≥91.0 | |

| YG6 | K20 | 14.7-15.1 | ≥1670 | ≥89.5 | Qualified for finish machining and semi-finish machining for the cast iron, non-ferrous metal, alloy and unalloyed materials. Also qualified for wire drawing for the steel and non-ferrous metal, electric drill for geology use and steel drill etc. |

| YG8 | K20-K30 | 14.6-14.9 | ≥1840 | ≥89 | Qualified for rough machining of cast iron, non-ferrous metal, nonmetal materials, drawing of steel, non-ferrous metal and pipes, various drills for geology use, tools for machine manufacture and wearing parts |

3. Silicon carbide sand blasting nozzles

have middle wear resistance and anti-shock ability compared with boron carbide and tungsten carbide, and much lighter than tungsten carbides.

Estimated service life of nozzles (In hours)

Nozzle Material |

Steel Grit/Shot |

Sand |

Aluminum Oxide |

Alumina |

20-40 |

10-30 |

1-4 |

Tungsten Carbide |

500-800 |

300-400 |

20-40 |

Silicon Carbide |

600-1000 |

400-600 |

50-100 |

Boron Carbide |

1500-2500 |

750-1500 |

200-1000 |

Member Information

| Grewin Carbide Company | |

|---|---|

| Country/Region: | Hu Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 17336629280 |

| Contact: | Cindy (Sales Manager) |

| Last Online: | 07 Mar, 2019 |

Related Products of this Company

-

Tungsten Carbide CNC Turning Inserts

US $0.3

-

B0820m06 8X20X6X65 Solid Cemented

US $1.13