| Model: | DQ-50 |

|---|---|

| Brand: | Solid was |

| Origin: | Made In China |

| Category: | Industrial Supplies / Other Industrial Supplies |

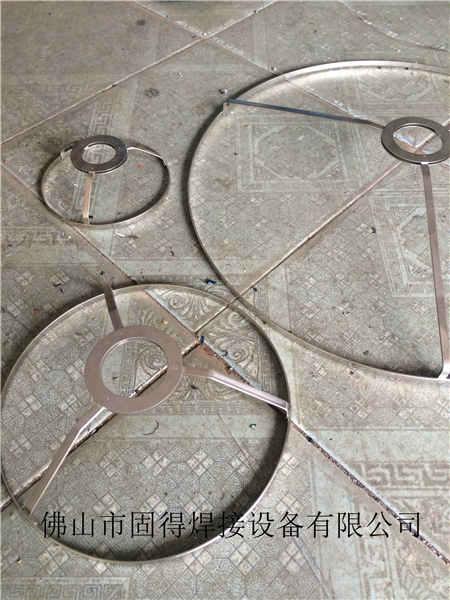

| Label: | Looped machine , Automatic looping ma , Circle welding machi |

| Price: |

¥68000

/ pc

|

| Min. Order: | 1 pc |

Product Description

Automatic looping welding all-in-one machine is composed of (1) wire straightening mechanism,(2) wire length precision detection mechanism,(3) wire traction mechanism,(4) looping forming mechanism,(5) looping and cutting off butt welding mechanism at both ends and (6) control system that coordinates the work of these mechanisms.

One (1) steel wire straightening mechanism is composed of two groups of perpendicular adjustment wheel, the internal stress of the alignment of the steel wire and steel wire adjustment function, looped before welding production, into the wire, need to manually adjust the adjustment pressure turn place to meet the requirements of steel wire straightening. (2) the wire length precision inspection agencies throughout the system have the accuracy requirement of looped circumference, box of high precision wheel and photoelectric encoder and the roller,Roller with the encoder wheel pressure, cylinder pressure looped manually before welding voltage solenoid valve switch on wheel pressure wire. (3) wire traction mechanism driven by ac servo motor and cycloidal pinwheel reducer counter rotating gear box, steel wire clamp device, precise wire feeding effect in the whole system, (4) by 2 looped forming mechanism are fixed wheel molding and forming a mobile wheel, mobile transfer molding wheel with screw structure, and with a locking device. (5) looped cut off both ends butt welding institution by wire cutting machine, steel wire grab transfer device,Alignment device, a butt welding device, played a looped cut off in the whole system, on both ends of the alignment, the role of butt welding. (6) control system by the control of the equipment of the programmable controller (PLC) and auxiliary circuit, man-machine interface touch screen, butt welding controller and man-machine interface and its circuit, each part of the equipment of sensors. Control of the whole equipment stable looped welding effect.

1.1. Overview of working principle

2. The wire from the preset motorized pay-off, after (1) steel wire straightening straightening mechanism, in (2) the wire length precision inspection agencies, and (3) wire traction institutions under the cooperative work of straightening steel wire after precision transfer to preset fixed length (4) the diameter of the circle of dozen circle looped shape forming mechanism, forming for the length of 1 + 1/4 circle circle, including 1 looped the loop position in (5) looped cut off both ends butt preset position and all the conditions, after being cut off,With looped clamping device for clamping transferred to the welding electrode position, and alignment device has aligned on both ends of the wire, then use butt welding device for welding wire ends of looped finished welding. Set in advance of the above process, all the actions (6) control system for automatic control process, without human intervention.

3. Equipment installation

Equipment weight of 0.85 tons, covers an area of 2.5 square meters. The equipment in any smooth cement floor can bear more pressure can be installed in horizontal, but the ground tilt shall not be greater than 3 degrees. Under the condition of uneven ground equipment can anchor mat iron guarantee in place on the ground shaking, to reduce the vibration of the equipment is working noise available anchor bolts fixed equipment. Equipment placed workshop dust concentration standards shall not be less than the numerical control machine tool of the above environmental requirements. The workshop temperature requirements of 0-45 degrees, relative humidity shall not be greater than 80%.

Requirements for power connection and air source connection of equipment:

Note:

Equipment power saving: the equipment shall be connected to 380V power supply of 3-phase 4-wire system, and 3 live wires and 1 null wire shall be connected according to the figure. If the connection is wrong, the equipment control system will be burnt down.

Equipment air connection: the equipment shall be connected to the system with a pressure of 0.8-1.2kgf /cm2, a storage tank with a volume of more than 120 liters, and a nominal flow rate of more than 1.0m3 /min. It shall be connected to the equipment through a drying device.

Equipment grounding: the equipment enclosure shall be grounded.

Member Information

| foshan good welding equipment co,ltd | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13687427266 |

| Contact: | zhong ya xian (manager) |

| Last Online: | 26 Mar, 2019 |