| Model: | DG75-II DG95-II |

|---|---|

| Brand: | DG |

| Origin: | Made In China |

| Category: | Industrial Supplies / Food, Beverage & Cereal Machine |

| Label: | Corn flakes machine , Cereal ball extruder , food extrusion |

| Price: |

US $30000

/ pc

|

| Min. Order: | 1 pc |

Product Description

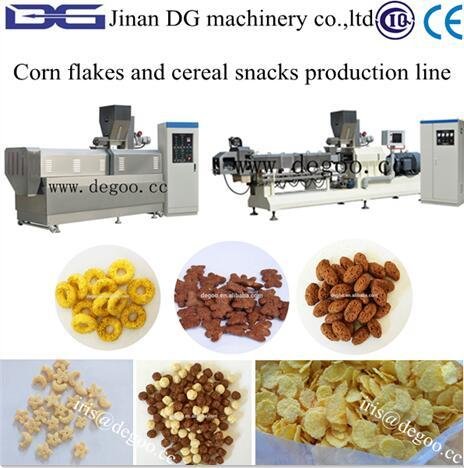

Brief introduction of the corn flakes and nutritional cereal processing line:

1. Raw Materials: Main corn Powder and Other Cereals Powder

2. Products: All kinds of snacks with different shapes and types.

3. Capacity: 60-80 KG/H,100-150KG/H ,200 -250KG/H,300-350 KG/H

4. Flow Chart: Mixing —Extruding —Flaking —Drying — Baking —Coating —Baking —Cooling

5. Voltage: Three phases: 380V/50HZ, Single phase: 220V/50HZ,

also can make it according to customers' local voltage of different countries

6. Machines Materials: All the machines are made by food grade stainless steel.

Technical Parameters of Breakfast Cereal Production Line :

| Model | Installed power | Power consumption | Throughput | Dimension |

| DG32-II processing line | 135KW | 101KW | 60-80kg/h | 45X2.8X2.7M |

| DG52-II processing line | 210kw | 168KW | 100-150kg/h | 54.7X2.8X2.7M |

| DG75-II processing line | 292KW | 219KW | 200-250kg/h | 64.2X3.2X3.1M |

| DG75-II B processing line | 342KW | 256KW | 300-350kg/h | 69X3.3X3.8M |

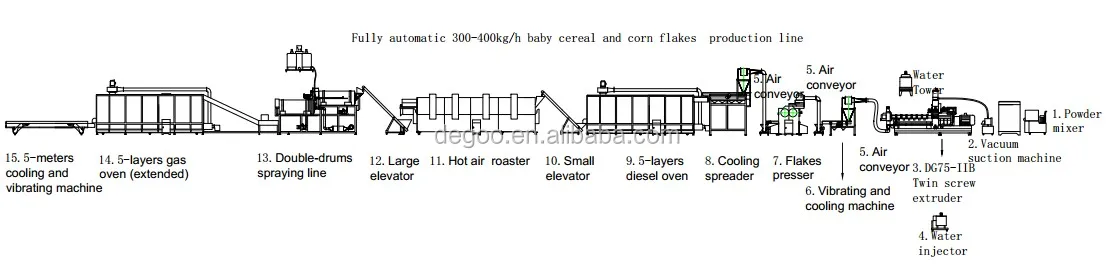

CAD drawing of Corn Flakes and Breakfast cereal production line (Example:300-350kg/h):

Brief introductions of single machines of the corn flakes and cereal processing line:

1.Flour mixer : to mix various raw materil evenly.

2.Screw conveyor : to convey raw material to extrude

3.Twin/Double screw extruder :to extruder and cook the raw material into different shapes breakfast cereal

4.Water injector: to inject water on the producing process.

5.Vibrating cooler: to spread the products and cool it quickly.

6.Air conveyor: to convey the food to the next machine

7.Flakes presser: to press the particles into thin flakes (its size of flakes can be adjusted)

8.Higher vibrating cooler: to spread the flakes and sancks food and cool it quickly.

9.Belt drying oven: to dry snacks food by circulating belt.

10.Belt conveyor: to elevate the snacks food to the next machine

11.High temperature toaster: to use hot air to dry the snacks food.

12.Flavoring machine: to spray flour ,sugar oil and other seansons on the food to get decilious food.

13.Extending drying oven: to dry the corn flakes after it being coated sugar.

14.Cooling conveyor: to cool food.

Our Service & Turnkey Solution

a.) Consultation service before, during,and after sales;

b.) Project planning and design service;

c.) Deb ing of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

e.) Training of equipment maintenance and operating personally;

f.) New production techniques and formulas;

g.) Provide 1 year complete warranty and life-time maintenance service.

Product Presentation

Description of the machine :

Process:

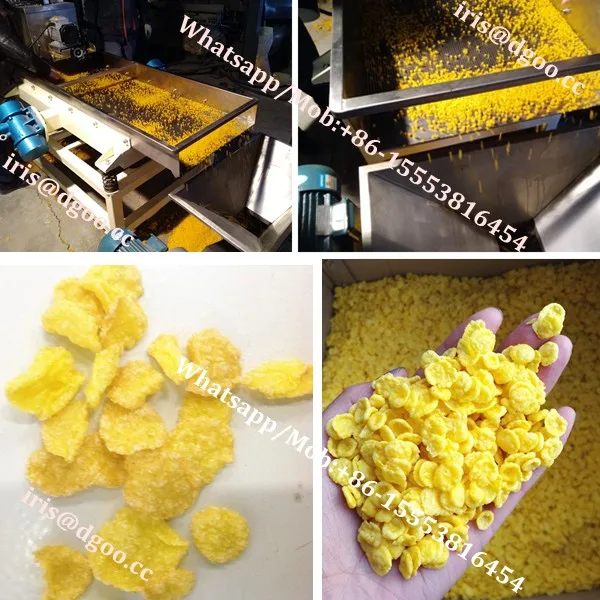

Flour mixing →extruding→cooling→flakes pressing→pre-drying→toasting→flavoring→drying→cooling

Features:

1.The line useds corn flour ,wheat flour,oat,buckwheat etc as raw material ,also can add little cocoa ,sugar and water to mix evenly.

2.After extruding,shaping particle,then being pressing to flakes ,drying ,spraying and flavoring .It can be made sweet ,salt and other crispy snacks food.

3.The breakthrough: No flakes sticky,big capacity,shaping best ,crispy taste, low cost.

4.By changing diferent dies to produce differnet shapes products.

5.Different screw combination can produce different products.

Products:

Contact:

Jinan DG machinery company:

Our machines are widely used on the below field:

1)Corn flakes and breakfast cereal production line

2)3D 2D snack pellet production line

3)Caramel hot air popcorn production line

4)Corn puffed snack food production line

5)Chocolate filled snack food production line

6)Bread crumbs production line

7)Cheetos Nik nak Kurkure snack food production line

8)Artificial rice production line

9)Pet food production line

10)Nutritional rice powder production line

11)Soy Protein snack food production line

12)Fried cone sala bugle snack food production line

Member Information

| Jinan DG machinery company | |

|---|---|

| Country/Region: | Shan Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 15553816454 |

| Contact: | iris (Manager) |

| Last Online: | 15 Mar, 2019 |

Related Products of this Company

-

Oshish corn flakes kellgos cereal

US $30000

-

3d 2d fried slanty chips pellet snack

US $40000

-

fortified rice /artificial extruder rice

US $40000

-

Ball American popcorn caramelizer sifter

US $20000

-

American Cretors caramel popcorn machine

US $12000

-

Fruit loops ring cereal snack food

US $20000

-

Nutritional extruded baby rice powder

US $30000