| Model: | SWT-NS620C |

|---|---|

| Brand: | MM-Tech |

| Origin: | Made In China |

| Category: | Industrial Supplies / Industrial Supplies Stocks |

| Label: | PE Granules welder , PP pipe weld machine , geomembrane welder |

| Price: |

US $2500

/ set

|

| Min. Order: | 1 set |

Product Description

Hand Held Plastic Extrusion Welder are also called Extrusion welding gun, Hand held Plastic Extrusion Welding Machine,Hot Air Plastic Welder Gun extruder,Plastic Hand Held Extrusion Welder,Plastic Extrusion welding gun,Extrusion Welder,Hand Held Extrusion Welder,hand extrusion welding equipment,hand extruder for plastic, manual extruder,Extrusion welding gun,plastic extrusion welder,hdpe hand extruder for PP rods,hand extrusion welder gun for welding HDPE/PP/PVDF sheet/pipes and fittings,Plastic hand extrusion welder for HDPE membrane PP pipe,Geomembrane extrusion welding machine for tank or pipe,Plastic Granules Extrusion Welder,Thermoplastic Welding using Hand Held Extruder,

Hand held Plastic Extrusion Welding Machines are designed for water conservancy,aquaculture,landfills,chemical mining,sewage treatment,roof construction, and other waterproofing projects.

SWT-NS 620C Plastic Extrusion Welder

Hand Held Plastic Extrusion Welder are also called Extrusion welding gun, Hand held Plastic Extrusion Welding Machine,

Product Overview

SWT-NS Model extrusion welder is a new type of hot air welder which imported foreign advanced technology, well-developed.

It has reached or exceeded the same type products of oversea, filling the domestic blank. The major components (hot air gun and drive motor) are made of imported brand-name accessories, stable performance, long service life; They are two independent systems,one is for preheating raw material,another is for welding rod extrusion. Reasonable structure, convenient operation, continuous welding, high working efficiency, powerful extrusion, to make the weld strength is greatly improved,It is the ideal product for a variety of thermoplastic welding processing.

This product is with two major components,preheating raw material’s hot air part and welding rod’s extrusion part.Hot air part with adjustable temperature controller to heat automatically,and extrusion part with independent thermostatic heating control system to send hot air independently, It is easy to adjust extrusion speed and use screw extruding for powerful extrusion pressure. Using 220v power supply uniformly to weld plastic sheets,tube and other thermoplastic products,especially for both ends of large diameter hollow wall pipe,producing pipe and repairing pipe and so on.

Available welding materials: thermoplastic HDPE, PP, PVDF, especially PE .Do not apply in a conductive plastic (PE-EL),

or cause the machine to produce a conductive short-circuit.

Replacement of the different welding nozzle, can be applied:

Plastic containers’ welding, stitching, etc.;

The large diameter plastic pipe’s welding, repairing, splicing, sealing, etc.;

The thicker plastic membranes, geomembrane splicing, patching and so on.

Product Features

Imported hot air welding torch and imported driven system, high temperature, big torque, long service life, stable performance.

Light weight, easy to handle and available to operation at different angles.

Big extrusion volume can be welded more than 10mm welding seam.

Different welding shoes can be applied to different types of welding.

It is used in the tank and pipe and is comply with Part 4 of the DVS standard (Germany Welding Association).

Product Detailed

This series of welding machine is powerful with high welding speed and good welding quality.

It is available for welding PE, PVDF, PVC, PP and other hot melt materials.

It is the first one to have a digital display control, 360 degree rotating welding head,

the motor cold start protection, independent heating of welding rod and membrane material and other functions in China.

International warranty 24months.

Any parts broken or does not work under normal operating,we are free to provide.

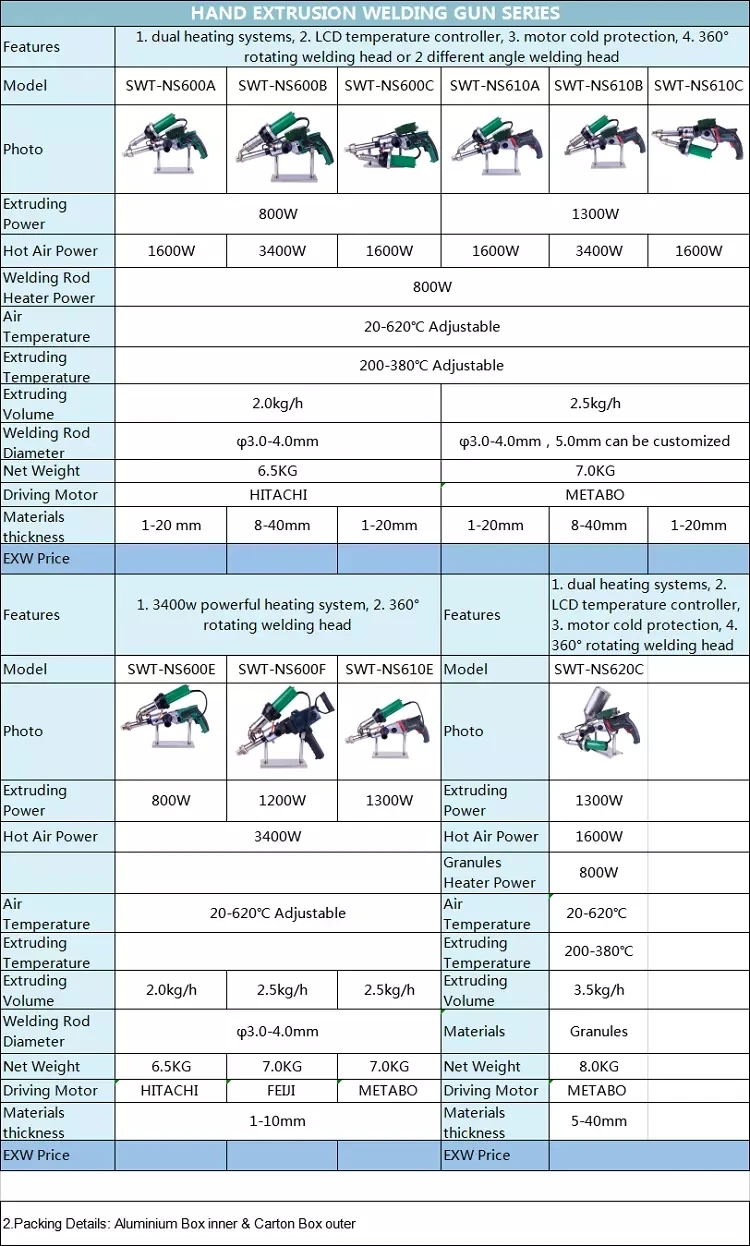

Technical Parameters For Plastic Hand Held Extrusion Welder:

|

Item no.: |

SWT-NS620C |

|

Voltage: |

220V |

|

Frequency: |

50/60HZ |

|

Exruding Motor Power: |

1350W |

|

Hot Air Power |

1600W |

|

Plastic Granules Heating Power |

800W |

|

Wind temperature: |

20-600°c |

|

Heating temperature when extruding: |

200-380° c |

|

Welding speed: |

3.5kg/h |

|

Weight: |

8.0kg |

|

Usage: |

pvc tarpaulin welding extruder |

Features

1.Vinyl Weld Extruder Welder Machine

2.Adjustable preheat extension

3.Solid, durable construction, easy operation

4.Suitable for welding PE, PP, PVDF

Images of Hot Air Plastic Welder Gun extruder:

More Products

Application of Hand Held Extrusion Welder :

Hand Held Plastic Extrusion Welder is used for welding PE, PP, PVC, PVDF, HDPE and so on.

Hand held Plastic Extrusion Welding Machines are used for plastic sheets, and bitumen waterproofing and packaging materials with hot air for tanks and lining and agricultural and environmental cover.

Welding machines for polypropylene and polyethylene pipes.

Hand held Plastic Extrusion Welding Machines are designed for water conservancy,aquaculture,landfills,chemical mining,sewage treatment,roof construction, and other waterproofing projects.

Member Information

| Hebei MingMai Technology Co.,LTD | |

|---|---|

| Country/Region: | He Bei - China |

| Business Nature: | Manufacturer |

| Phone: | 18032037893 |

| Contact: | Emma (manager) |

| Last Online: | 18 Feb, 2020 |