1. Specification

1.1. Material AA303 alloy;

1.2. Temper: O,H14,H16 is typical;

1.3. Dimension

Width from 450mm to 1300mm, Thickness from 0.08mm to 2mm;

Tolerance for width ±1mm,Tolerance for thickness ±0.01mm;

1.4. Mechanical Properties

Meet industry standard and China standard or custom standard

1.5. Chemical composition

Silicon: Max 0.6%;

Iron: Max 0.7%

Copper: 0.05 to 0.20%

Manganese: 1.0 to 1.5%

Magnesium: Max 0.05%

Chromium: Max 0.05%

Zinc: 1.2 to 1.8%

Bismuth: Max 0.05%

Zirconium: Max 0.05%

Titanium: Max 0.05%

Aluminum: Remainder

1.6.Depth of Curvature

In any length or width of 1 meter of the material,the depth of arc shall not exceed 2 mm.

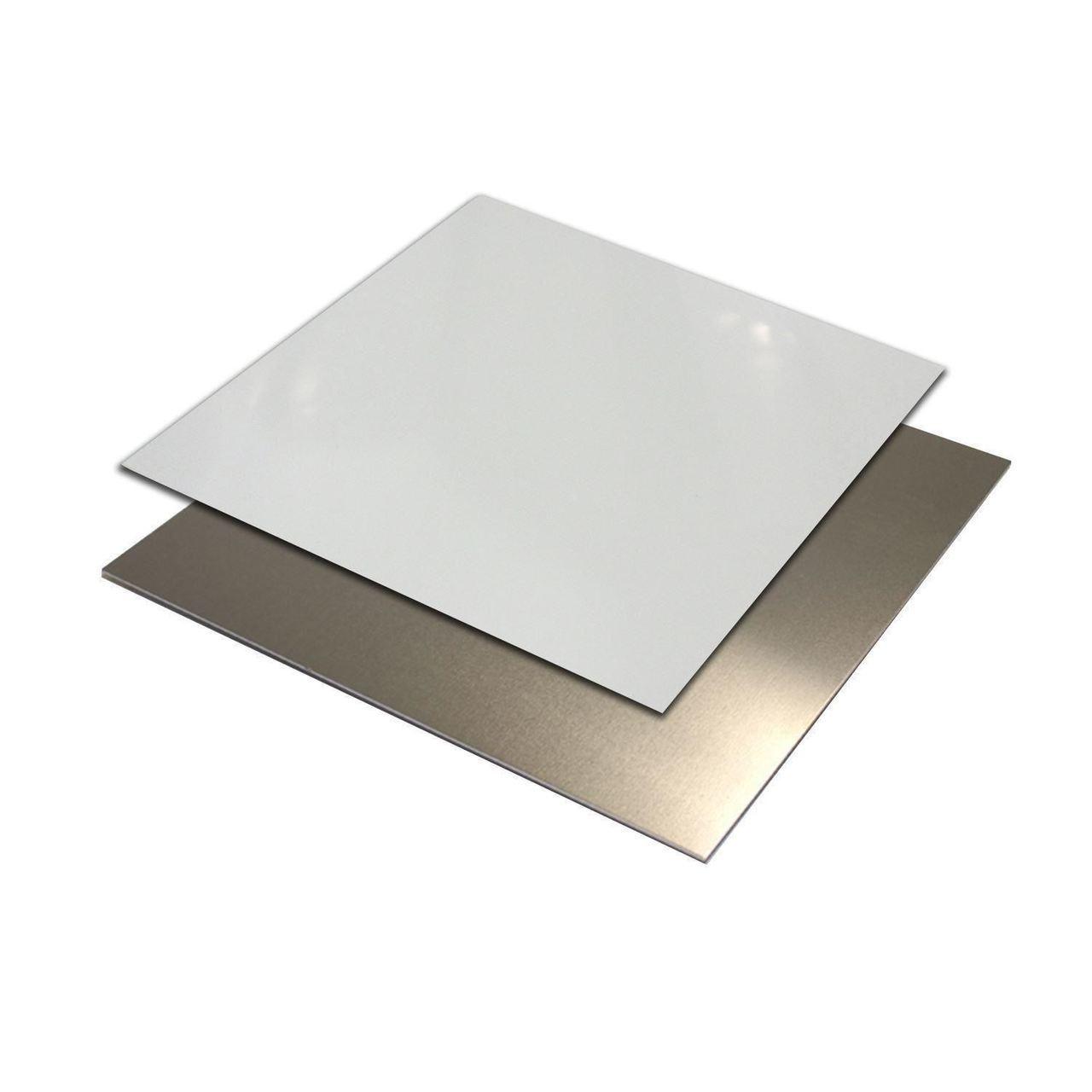

2. Surface finish

a. The material shall be free from pinholes and tearing;

b. The material shall be free waves and buckles;

c. The slit edges must be free from burrs and shall be straight and parallel.

3. Packing details

To be packed in wooden boxes with card board and cutting with paper core in-between the coil max package weight 1500 kgs.

a. The coil eye dia shall be around 250/300mm;

b. The coil outside dia shall be no more than1350mm;

c. Packing shall not leave any damages to the slit edges or shall not collapse in the inner;

d. Coil orientation in clockwise direction and eye to sky.

4. Marking

Each box to be legibly marked with the name of the manufacturer or supplier, the alloy designation of material,condition,dimensions and weight.

5. Application

Typically used in heat exchange field