| Model: | S-HR32UV3 |

|---|---|

| Brand: | LC |

| Origin: | Made In China |

| Category: | Industrial Supplies / Plate Making & Printing Machine |

| Label: | Auto cups printer , automation , cups screen printer |

| Price: |

US $110069

/ pc

|

| Min. Order: | 1 pc |

Product Description

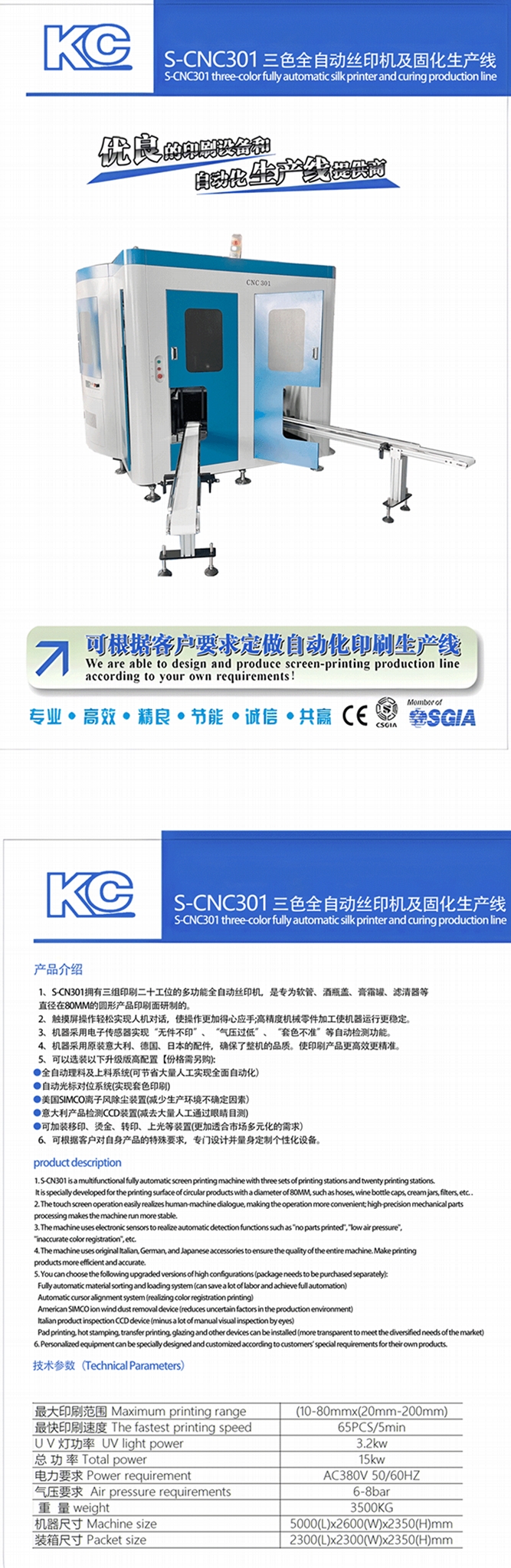

Creams, creams and other products in cosmetics that are between solid and liquid are usually stored in large-mouthed plastic boxes. This kind of cosmetic box is the first choice to use silk screen printing machine. Both the dragon screen printer and the rotary screen printer can print, but the rotary screen printer occupies a relatively small area, and it is easier to complete color registration, and it is used by more customers. At present, there are about 10 printing machinery manufacturers in China that produce such rotary screen printing machines. The precision of the turntable screen printing machine is related to the precision of the divider that controls the turntable, the processing precision of the rotating parts, and the precision of the servo system.

The rotary screen printing machine is composed of a feeding conveyor belt, a feeding device, a rotary table, a servo positioning system, a screen printing system, a UV curing system and a blanking system, which represents the highest level of current Chinese screen printing machine manufacturing technology.

|

S-HR32UV3 Full automatically Soft-tube screen printing machine/Structure |

|

|

Feeding device |

Conveyor, customized feeding system |

|

Direction identification |

Sensor, automatically identification |

|

Surface treatment |

Flame treatment, automatically lights |

|

Working table |

36-station stand rorating working table |

|

Actions |

Precision indexing disc Rotating transport |

|

Max Printing diameter |

70mm |

|

Max Printing Length |

200mm |

|

Rubber squeegee controlling |

High precision guide shaft |

|

Ink drying device |

UV Dying system |

|

Discharging |

Conveyor |

|

S-HR32UV3 Automatically Soft-tube screen printing machine//Usage and characters |

|

|

Guide |

|

|

Application fields |

|

|

S-HR32UV3 Full automatically screen printing Machine//Parameter |

|

|

Technical parameters |

|

|

Works supply |

|

|

Package list |

|

|

H.S.Code |

8443198000 |

|

Certificate |

CE |

|

S-HR32UV3 3-color full automatically screen printing machine//Advantage |

|

|

Function |

|

|

Main configuration |

|

| Summary: | Creams, creams and other products in cosmetics that are between solid and liquid are usually stored in large-mouthed plastic boxes. This kind of cosmetic box is the first choice to use silk screen printing machine. Both the dragon screen printer and the rotary screen printer can print, but the rotary screen printer occupies a relatively small area, and it is easier to complete color registration, and it is used by more customers. At present, there are about 10 printing machinery manufacturers in China that produce such rotary screen printing machines. The precision of the turntable screen printing machine is related to the precision of the divider that controls the turntable, the processing precision of the rotating parts, and the precision of the servo system. The rotary screen printing machine is composed of a feeding conveyor belt, a feeding device, a rotary table, a servo positioning system, a screen printing system, a UV curing system and a blanking system, which represents the highest level of current Chinese screen printing machine manufacturing technology. |

|---|---|

Member Information

| LC industrial company Limited | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13592766499 |

| Contact: | Mr kelven bai (Sales Manager) |

| Last Online: | 08 Nov, 2024 |

Related Products of this Company

-

pad printer with pad clead

US $2368

-

Plate drying closet

US $1750

-

Stand pad printer(PM1-250)

US $2617

-

Pneumatica Streching machine

US $2441

-

Flat/Cylinder Hot stamping machine

US $1617

-

Shuttle pad printer( PM2-250L)

US $3323

-

Screen printing machine( S-400E)

US $2573

-

Shuttle pad printer SP6-406

US $5265

-

Shuttle pad printer( SPM4-150L/2P)

US $5559

-

Tank Conveyor style pad printer SPM4-200

US $4800