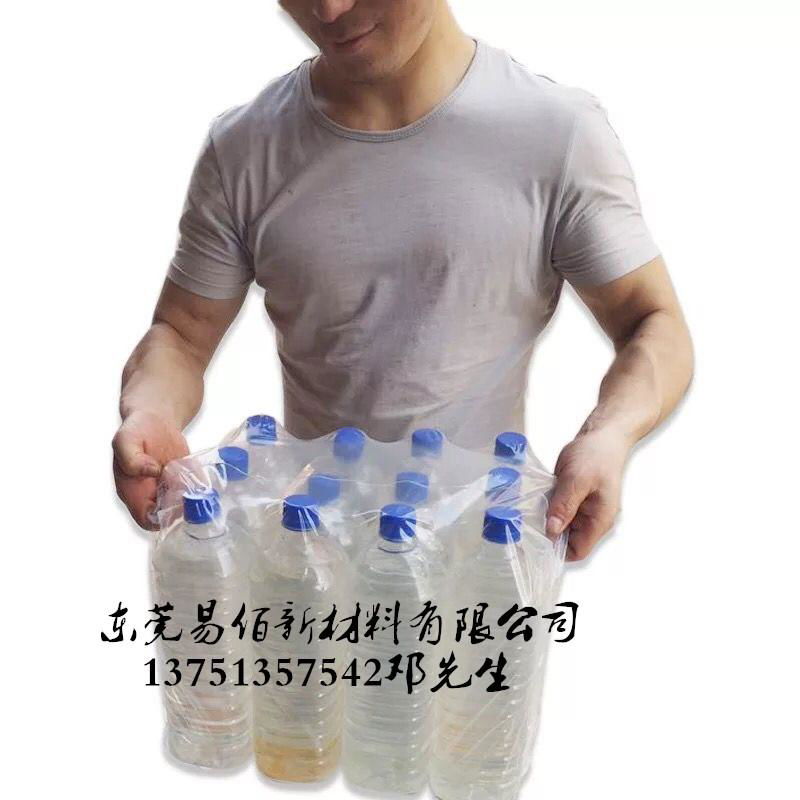

~Our factory specializes in the production of PVC.PE.POF heat shrinkable film, which can be made into shrinkage bags, single rolls, folding rolls, arcs, barrels and so on. PE heat shrinkable film is widely used in wine, cans, mineral water, beverages, cloth and other products of the whole assembly packaging, the product has good flexibility, impact resistance, tear resistance, not easy to damage, not afraid of moisture, shrinkage rate is large; The film has the characteristics of high transparency, good gloss and high shrinkage. POF has the characteristics of high gloss, good toughness, high tear strength, uniform thermal shrinkage and suitable for automatic high-speed packaging. It is a replacement product of traditional PVC thermal shrinkage film. POF is the meaning of thermal shrinkage film. POF is called multi-layer co-extrusion polyolefin thermal shrinkage film. It is made of linear low density polyethylene (LLDPE) as the intermediate layer, and polypropylene (pp) as the inner and outer layer through three extruders, and then processed by die forming, bubble blowing and other special processes. Unit of test method for properties and properties of POF shrinkshrinkshrinkfilm film film film film properties unit of test methods Represent numerical thickness Micron/15 19 25 density g/cm3/0.920 0 0.920 0 0 0.920 0 0 0.920 tensile properties/MD/MD/TD MD/TD MD/TD MD/TD toughness N/mm2 ASTM-D882A 340/450 350/350/450 360/450 360/450 tensile strength N/mm2 ASTM-D882 ASTM-D882 ASTM-D882 110/110/110/110/100% tensile limit 110 tensile strength 110 TM-110-110-110-110/110-110/110-110-110-110-110-110-110-110-110-110-105/105 Sealing Strength g/mm3 N/mm2 Internal 870 57 1025553 12504949tear strength 1025553 12505531250049tear strength g/mm3 ASTM-D1938 5.5 9.5 9 9.5 14.5 friction coefficient admin. ASTM-D1894 0.26 0.25 0.25 0.24 shrinkage rate (temperature: 125oc-140oc) 0.26 0.25 0.24 shrinkshrinkage rate (temperature: 125oc-140oc)% ASTM-D2732 MD/TD 65/MD/TD/62/62 MD/TD/TD 60/60/60 optical properties fog% ASTM-D2732 optical properties fog% ASTM-D1003 2.5 3.5 3.3 photocphotocphotocphotocphotocphotocphotocphotocphotocphotocata D245TM 257 ASTM-D4587 87 87 POF and PVC heat shrinkable film per unit area weight are acceptable for comparison of varieties and specifications Permissible thickness, density, specific gravity per square meter, weight per kilogram of area packed with small volume items: electronic, disk, food, frozen food, pharmaceuticals, etc. POF film 15 micron 0.92 13.8 g 72.48 PVC film 25 micron 1.4 35g 28.57 package of medium volume items: AD milk, books, stationery, textiles, alcoholic products POF film 20 micron 0.92 18.4 g 51.35 g 51.35 g PVC film 30 micron 1.4 42g 23.81 package or collective package items The POF film with superior physical properties of 15 micron can completely replace 20-25 micron PVC film with 20-25 micron and 20 micron PVC film with 25-30 micron. The POF film with superior physical properties can completely replace 25-30 micron PVC film with 25 micron PVC film. The POF, PE and PVC properties of 35-50 micron PVC film can completely replace 35-50 micron PVC film with low density of PVC film. Its thickness is 0.92g/cm3, its thickness is thin, its cost is low (density is 0.93g/cm3), its thickness is large, its cost is high (density is 1.4g/cm3), its thickness is large, its cost is high, its physical properties are thin and tough, its thickness is uniform, its quality is smooth, its transparency is good, its luster is high, its thickness is different, its texture is rough and hard, its transparency is poor, its luster is low, its thickness is brittle, its thickness is uneven, its texture is rough and hard, and transparent. Commodity value 1, low temperature resistance, no hardening and brittleness at - 400C, low temperature resistance, not easy to aging. 2. Good heat-sealing performance, high transparency and luster, soft feel, can improve product packaging grade 1. Low temperature resistance, cold in winter will harden but not easy to embrittle, but to increase the thickness is not easy to crack. 2. Poor transparency, rough surface, slightly worse visual effect than POF after packaging 1. Poor cold resistance, brittle hardening in cold or winter, easy to crack. 2. Transparency and glossiness are generally safe. The four corners are soft after contraction, and will not cut the skin. The four corners after contraction and packaging are hard and have poor hand feeling, but they are not easy to cause damage. Shrinkage packaging is hard and sharp, so it is easy to scratch hands. Environmental protection is non-toxic, degradable, and does not produce toxic gases during heat seal processing, environmental protection is non-toxic, does not produce toxic gases during heat seal processing, and produces odor and toxic gases during heat seal processing. Specification: 0.15mm-0.3mm according to customer requirements