◇ Automatic knife depth adapting system can help easily find the best knife depth value as it changes to new or different knife.

◇ It can continue to cut 1 to 10m paper . During the process of cutting, it can suck the paper automatically.

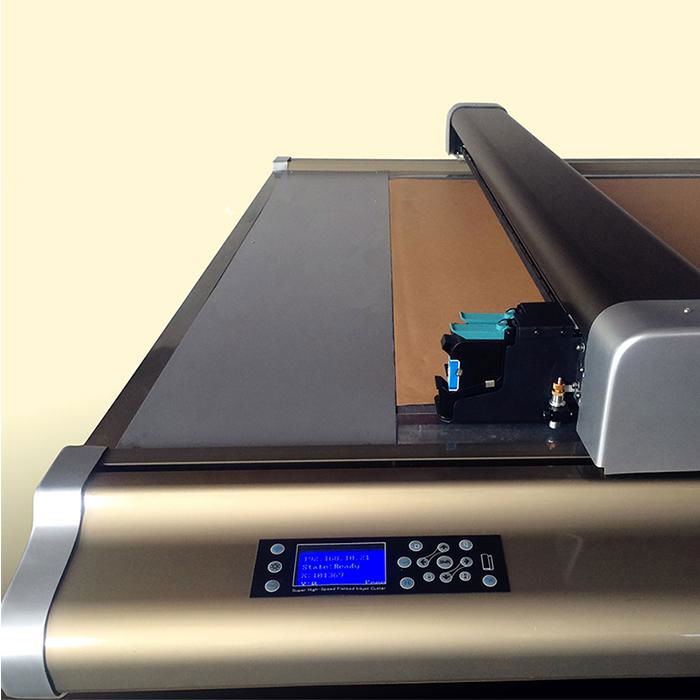

◇ Intelligent controller supports the long distance data transmission. It is quiet when the machine is working

◇ Automatic feeding paper system ensures accuracy feeding . The operation is easy. The independent feeding rack can bear 50kg paper.

◇ Standard equipped adsorption platform and low noise air pump.

◇ Cutting Accuracy:0.1mm allowance.

◇ Max. Cut thickness: 2mm for Paper Board, 1mm for the PVC etc.

◇ Cut Curve :Auto smooth and optimized technology for the curve, it can cut more accuracy.

◇ Files formats :HPG, HP-GL and GP-GL, Directly driver by Autocad etc.

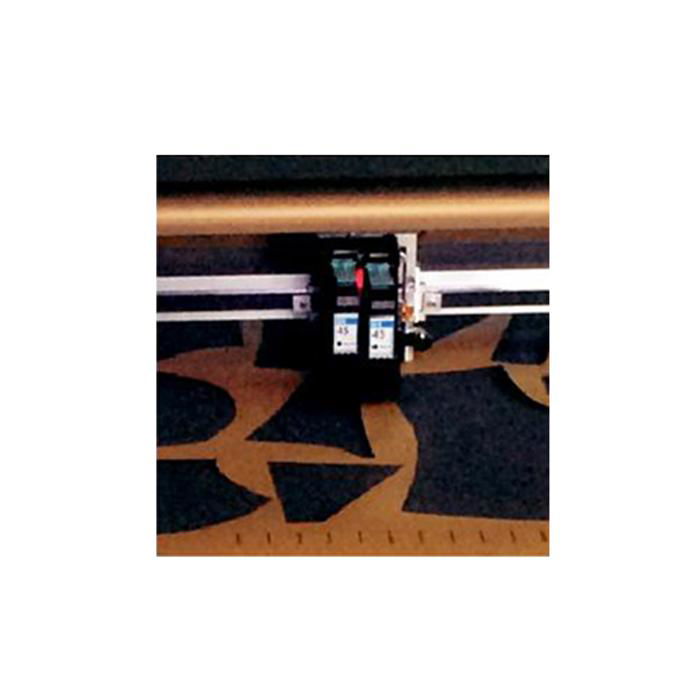

◇ Inkjet/Cut Heads :Double heads design: Two HP45 cartridges and 2nd Cut-head to cut.

◇ Inkjet/Blade Type: Knife type: Normal knife to cut 1mm paper board: the Hp45 Cartridges to be working by free maintenance

◇ Cut Materials:60gram to 800gram weight paper board, and normal 0.1-0.2mm plastic board,man-made leather for home furniture etc. industry.

◇ Materials sorption: Low-noise Vacuum System With Powerful Air Pumps as standard

◇ Power: Cutter: 800W, AC 220±10%,50HZ; Air Pump:1500W, AC 220±10%,50HZ;

◇ Port : Super LAN Port

◇ Main Shaft:Control by Advanced Servo control system, Servo motor as Optional.