Description:

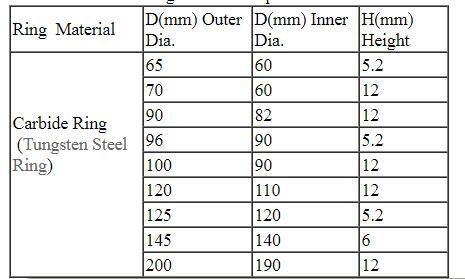

Carbide Rings For Ink Cups

Pad Printing Ceramic Rings and Carbide Rings for inkcup

There has been much debate as to which doctor ring material is best for doctoring printing plates. The market for pad printing supplies originally started with carbide steel doctor rings and many were successfully implemented, however, since the ceramic ring was brought to the market it has been extremely successful as well. We would guess that now the pad printing marketplace is evenly divided between the carbide ring and the new generation ceramic doctor ring. Today, both carbide rings and ceramic rings work extremely well. It is our opinion however, that the ceramic doctor ring offers some advantages.

1. One of the primary advantages of the ceramic ring has a "self-lubricating" qualities that make I work equally well on thin steel and thick steel and the softer polymer printing plates. The carbide doctor rings are generally fairly sharp and abrasive and will wear a polymer plate material quickly.

2. Another advantage of the ceramic ring is that it is generally thicker, more robust and resistant to damage by during handling. Most ceramic rings taper from the inside and outside diameter to a "point" roughly. 006" leaving plenty of material near the tip. Carbide rings, however, taper from the outside diameter only to a "point" with a cross section of. 003" leaving only a minimum amount of material near the tip resulting in more damage during operator handling. The combination of the ring profile and the brittle nature of carbide make damage to rings fairly frequent during ordinary use.

In general, the quality of pad printing supplies has become very high, so any type of sealed inkcup or ring material allows making excellent imprints.