| Model: | FLDCD006 |

|---|---|

| Brand: | FLD Filter |

| Origin: | Made In China |

| Category: | Industrial Supplies / Rubber & Plastics Machine |

| Label: | polymer filter , leaf filter disc , porous filter |

| Price: |

US $420

/ pc

|

| Min. Order: | 3 pc |

Product Description

Description

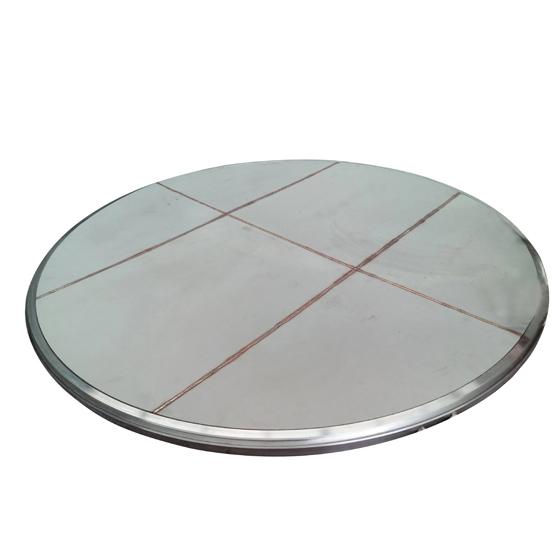

FLD filter produce polymer leaf filter disc for any sizes with any raw material. The pressure leaf filter elements consist of 5 layers or 3 layers or sintered stainless steel mesh, riveted or bolted depending on the requirements. Including 2 layers fine filter mesh, 2 layers supporting mesh and 1 layer for drain. They are held together by a tubular frame and there is mounted one or more pipes to let the filter liquid flow out.

The polymer filter disc is mainly used for vertical pressure leaf filter to handling the solid or liquid separation.

The vertical pressure leaf filter is mainly used for purification of edible and technical plant oil on different stages, primary purification, winterization, bleaching, hydrogenation, etc.

The filter elements enveloped with filter cloths are also available, with the professional experience in manufacturing the filter elements and excellent workman ship for many years.

The pressure leaf filter element does not consume the filter cloth, filter paper or filter cartridge, so the filter elements are widely used for many industries.

Features and Benefits

1.) High filtering efficiency;

2.) Complete enclosed filtration, no leakage, no environmental pollution;

3.) Easy cleaning;

4.) Low equipment cost and running cost, it is convenient to maintain equipment;

5.) The filter precision can reach the PPM level;

6.) Large filtration area;

7.) Excellent anti-acid, anti-alkahi, resist-temperature, resist-wearing; resist-recycling;

8.) Robust design;

9.) Bolted construction can be easily repaired onsite;

10.) Long service time;

Material: Filter Media Woven mesh or perforated mesh made of stainless steel 304, 304L, 316, 316L, 317L, 904L, & Monel Hastelloy etc.

Layers:

3 or 5 layers, or sintered.

Applicant:

1.) Edible oil industry;

2.) Beverage industry;

3.) Chemical industry;

4.) Pharmacy industry;

5.) Petrochemical industry;

7.) Vital oil distillation;

8.) Lube kind of oil re-refining;

Maintenance

1.) The sintered replacement basket filter and strainer is the filter core. The wire mesh belongs to the wear parts. It needs a special protection.

2.) After the filter has worked for some time, the impurities are removed in the filter core in time.

3.) When cleaning the impurities, the wire mesh should be care to ensure that the core is not deformed or damaged.

4.) Once the wire mesh is deformed or damaged, it should be replaced immediately.

The following parameter will be confirmed before order:

1.) Size;

2.) Work pressure;

3.) Operation pressure;

4.) Material;

5.) Flange standard;

6.) Dielectric;

Description

FLD filter produce polymer leaf filter disc for any sizes with any raw material. The pressure leaf filter elements consist of 5 layers or 3 layers or sintered stainless steel mesh, riveted or bolted depending on the requirements. Including 2 layers fine filter mesh, 2 layers supporting mesh and 1 layer for drain. They are held together by a tubular frame and there is mounted one or more pipes to let the filter liquid flow out.

The polymer filter disc is mainly used for vertical pressure leaf filter to handling the solid or liquid separation.

The vertical pressure leaf filter is mainly used for purification of edible and technical plant oil on different stages, primary purification, winterization, bleaching, hydrogenation, etc.

The filter elements enveloped with filter cloths are also available, with the professional experience in manufacturing the filter elements and excellent workman ship for many years.

The pressure leaf filter element does not consume the filter cloth, filter paper or filter cartridge, so the filter elements are widely used for many industries.

Features and Benefits

1.) High filtering efficiency;

2.) Complete enclosed filtration, no leakage, no environmental pollution;

3.) Easy cleaning;

4.) Low equipment cost and running cost, it is convenient to maintain equipment;

5.) The filter precision can reach the PPM level;

6.) Large filtration area;

7.) Excellent anti-acid, anti-alkahi, resist-temperature, resist-wearing; resist-recycling;

8.) Robust design;

9.) Bolted construction can be easily repaired onsite;

10.) Long service time;

Material: Filter Media Woven mesh or perforated mesh made of stainless steel 304, 304L, 316, 316L, 317L, 904L, & Monel Hastelloy etc.

Layers:

3 or 5 layers, or sintered.

Applicant:

1.) Edible oil industry;

2.) Beverage industry;

3.) Chemical industry;

4.) Pharmacy industry;

5.) Petrochemical industry;

7.) Vital oil distillation;

8.) Lube kind of oil re-refining;

Maintenance

1.) The sintered replacement basket filter and strainer is the filter core. The wire mesh belongs to the wear parts. It needs a special protection.

2.) After the filter has worked for some time, the impurities are removed in the filter core in time.

3.) When cleaning the impurities, the wire mesh should be care to ensure that the core is not deformed or damaged.

4.) Once the wire mesh is deformed or damaged, it should be replaced immediately.

The following parameter will be confirmed before order:

1.) Size;

2.) Work pressure;

3.) Operation pressure;

4.) Material;

5.) Flange standard;

6.) Dielectric;

| Payment Terms: | TT/LC/DP |

|---|---|

Member Information

| Country/Region: | Shan Dong - China |

|---|---|

| Business Nature: | Manufacturer |

| Phone: | 8613791313383 |

| Contact: | |

| Last Online: | 08 Nov, 2019 |

Related Products of this Company

-

Sintered Pleated Porous Metal Polymer

US $0.45

-

SS Metallic Extruder Screen Pack Disc

US $0.35

-

Buy Polymer Multi-layer Filter Disc &

US $0.5

-

Deals Plastic Exturder Screen Trim

US $0.5