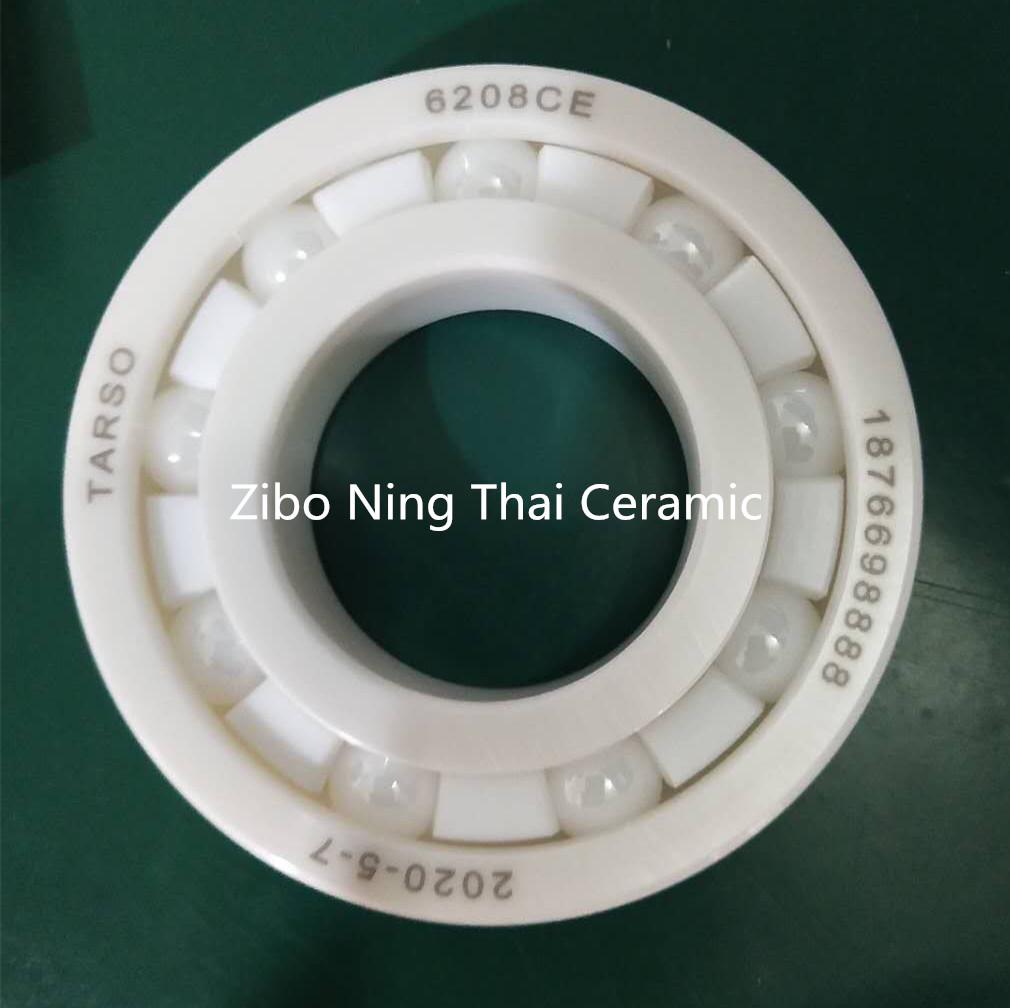

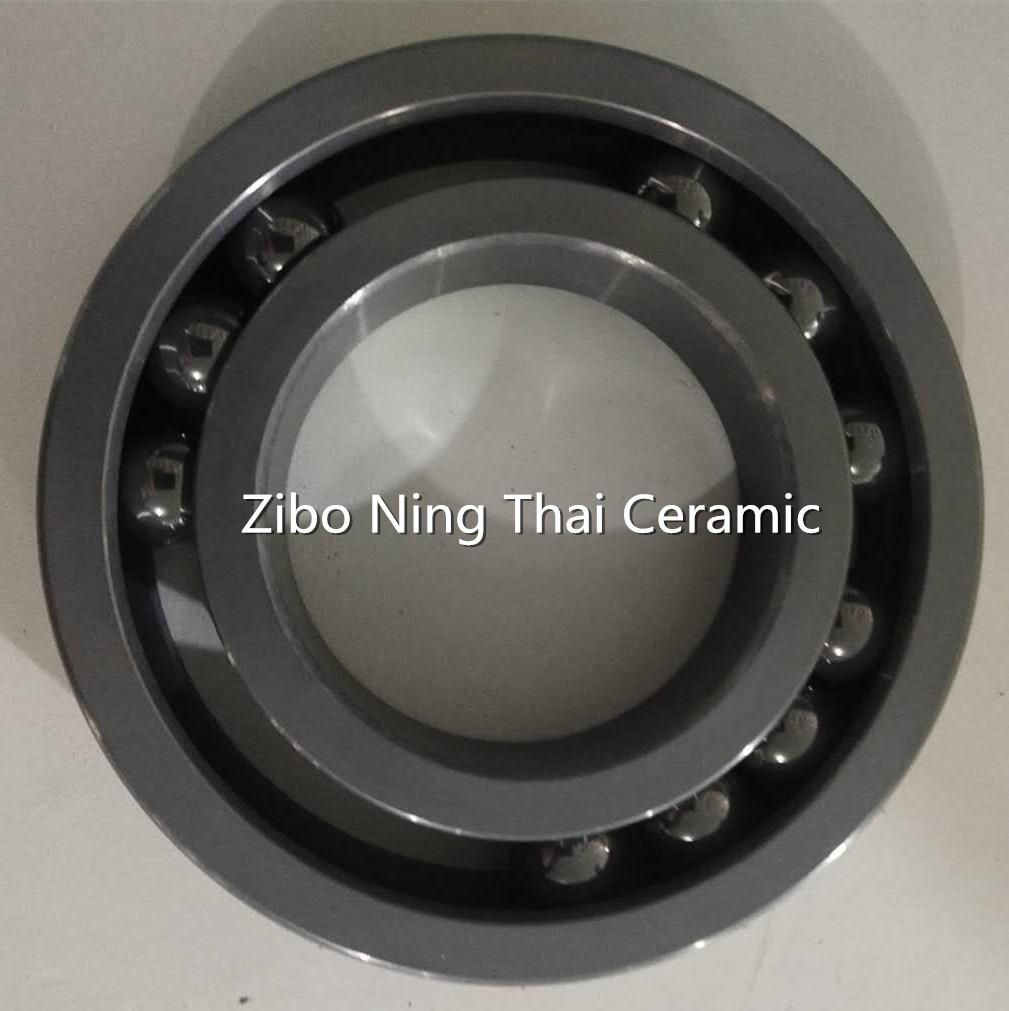

Ceramic bearing is the one of most important spare part in the machinery which has features with high and low temperature resistance, corrosion resistance, wear resistance, no magnetic, electric insulation, self-lubrication, high speed, long service life. It can be used in extreme harsh environment and special working conditions. At present, there are three kinds of material of Zirconia (ZrO2), Silicon nitride (Si3N4) and Silicon carbide (SiC). The bearing ring and rolling element are made of all-ceramic materials. With the PTFE, nylon 66, ultem, zirconium oxide, silicon carbide, stainless steel or special aviation aluminum manufacturing retainer, ceramic bearing application has expanded to high speed bearing, high temperature resistance bearing, corrosion resistant bearing , anti-magnetic bearing and electric insulation bearing which are widely used in industrial kiln, vacuum coating equipment, chemical equipment, semiconductor industry, LCD panel equipment, lithium battery material production equipment, biological pharmaceutical equipment, food machinery, etc.