| Model: | DFC-600型 |

|---|---|

| Brand: | Jin Jing brand |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Piping Tubing |

| Label: | Casting riser , Steel ingot , Riser |

| Price: |

-

|

| Min. Order: | 1 pc |

Product Description

Dfc-600 covering agent for heating and heat preservation of ingot and cast steel

Dfc-600 covering agent for heating and heat preservation of ingot and cast steel

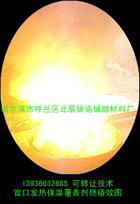

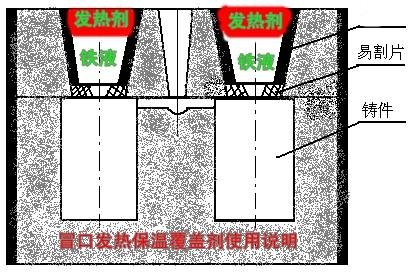

The new products developed jointly by our company and relevant scientific research institutions are suitable for open riser and sand mold common riser of steel ingot, cast steel and other castings, and also suitable for heating and heat preservation of medium-sized subcontracting metal liquid. Dfc-600 series products of ingot riser heat preservation and heat covering agent are applied to the surface of open riser, which can effectively insulate metal liquid from heat radiation, heat convection and reduce heat conduction through the riser surface 。 The product can obviously improve the shrinkage shape of the riser, make the surface of the riser shrink in the shape of (saucer) or (Pan), effectively prevent the formation of the tapered shrinkage surface and the central shrinkage pipe, increase the safe distance of the riser, and can be used in various ingots, steel castings and iron castings for heating and heat preservation, prevent the formation of the shrinkage hole of the casting, and prevent the temperature drop of the molten metal in the middle subcontracting. The yield of ingot, cast steel and cast iron can be increased by 25-35%, and generally the most conservative can be increased by 20%.

The new products developed jointly by our company and relevant scientific research institutions are suitable for open riser and sand mold common riser of steel ingot, cast steel and other castings, and also suitable for heating and heat preservation of medium-sized subcontracting metal liquid. Dfc-600 series products of ingot riser heat preservati on and heat covering agent are applied to the surface of open riser, which can effectively insulate metal liquid from heat radiation, heat convection and reduce heat conduction through the riser surface 。 The product can obviously improve the shrinkage shape of the riser, make the surface of the riser shrink in the shape of (saucer) or (Pan), effectively prevent the formation of the tapered shrinkage surface and the central shrinkage pipe, increase the safe distance of the riser, and can be used in various ingots, steel castings and iron castings f or heating and heat preservation, prevent the formation of the shrinkage hole of the casting, and prevent the temperature drop of the molten metal in the middle subcontracting. The yield of ingot, cast steel and cast iron can be increased by 25-35%, and generally the most conservative can be increased by 20%.

1、 Product performance:

1、 Product performance:

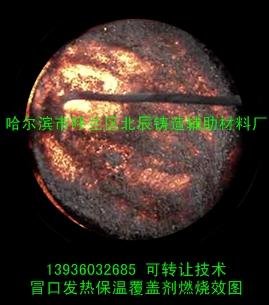

The riser heating and heat preservation covering agent is a black and gray powder reduction reaction with fast temperature rise, large heat value, smokeless, non-toxic, tasteless, dust-free and

The riser heating and heat preservation covering agent is a black and gray powder reduction reaction with fast temperature rise, large heat value, smokeless, non-toxic, tasteless, dust-free and

Harmful gas pollution, green environmental protection.

Harmful gas pollution, green environmental protection.

2、 Product use:

2、 Product use:

It is suitable for the heat insulation cover of open riser of ingot, cast steel and cast iron and common riser of sand mold, and it is also suitable for the heat insulation of molten metal in the middle subcontracting. Covering the riser, the product immediately burns and heats up, prolongs the setting time of the riser by 4-5 times, keeps the temperature for about 30 hours, and does not affect the quality of the original metal.

It is suitable for the heat insulation cover of open riser of ingot, cast steel and cast iron and common riser of sand mold, and it is also suitable for the heat insulation of molten metal in the middle subcontracting. Covering the riser, the product immediately burns and heats up, prolongs the setting time of the riser by 4-5 times, keeps the tem perature for about 30 hours, and does not affect the quality of the original metal.

3、 Product features:

3、 Product features:

1. The riser surface of this product shrinks in the shape of (saucer) or (Pan) without insulating riser sleeve

1. The riser surface of this product shrinks in the shape of (saucer) or (Pan) without insulating riser sleeve

2. The time of crusting at the top of the riser is obviously prolonged, which makes the steel water in the riser under the action of atmospheric pressure for a long time, and greatly improves the riser

2. The time of crusting at the top of the riser is obviously prolonged, which makes the steel water in the riser under the action of atmospheric pressure for a long time, and greatly improves the riser

The feeding efficiency is favorable for gas precipitation and inclusion floatation in the casting, so as to obtain sound casting and reduce scrap rate. Using this product, the riser weight can be reduced by more than 50%, and the technological yield of cast iron and cast steel can be increased by more than 15%.

The feeding efficiency is favorable for gas precipitation and inclusion floatation in the casting, so as to obtain sound casting and reduce scrap rate. Using this product, the riser weight can be reduced by more than 50%, and the technological yield of cast iron and cast steel can be increased by more than 15%.

3. The use of heat preservation covering agent in the middle subcontracting can prevent the slow cooling of the liquid metal in the middle subcontracting.

3. The use of heat preservation covering agent in the middle subcontracting can prevent the slow cooling of the liquid metal in the middle subcontracting.

4、 Scope of use:

4、 Scope of use:

It is suitable for the casting of steel ingot with riser diameter of 45-1000mm, cast iron riser casting, as well as the covering and heat preservation of molten metal in large ladle and induction furnace.

It is suitable for the casting of steel ingot with riser diameter of 45-1000mm, cast iron riser casting, as well as the covering and heat preservation of molten metal in large ladle and induction furnace.

5、 Performance and standard of ingot riser insulation coating agent:

5、 Performance and standard of ingot riser insulation coating agent:

1. Standard: in accordance with the factory standard:

1. Standard: in accordance with the factory standard:

2. Chemical composition list

2. Chemical composition list

Specific gravity of AI Fe2O3 AI2O3 Na2O Cao moisture content

Specific gravity of AI Fe2O3 AI2O3 Na2O Cao moisture content

15--30 3--10 30--50 ≦1-3 ≦2 ≦3 0.8-1.1 m ³

15--30 3--10 30--50 ≦1-3 ≦2 ≦3 0.8-1.1 m ³

| Payment Terms: | Bank remittance to delivery |

|---|---|

Member Information

| Harbin Hulan District Beichen foundry auxiliary material factory | |

|---|---|

| Country/Region: | Hei Long jiang - China |

| Business Nature: | Manufacturer |

| Phone: | 13936032685 |

| Contact: | Hai Lin Liu (manager) |

| Last Online: | 30 Sep, 2022 |