| Model: | DFC-600型 |

|---|---|

| Brand: | Jin Jing brand |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Stainless Steel |

| Label: | Riser heating agent , Riser insulation age , Heating agent for ca |

| Price: |

-

|

| Min. Order: | 1 pc |

Product Description

Basic description of heating agent for dfc-600 smokeless riser

Basic description of heating agent for dfc-600 smokeless riser

1、 Dfc-600 smokeless riser heating agent product features:

1、 Dfc-600 smokeless riser heating agent product features:

Model: dfc-600 smokeless and carbon free

Model: dfc-600 smokeless and carbon free

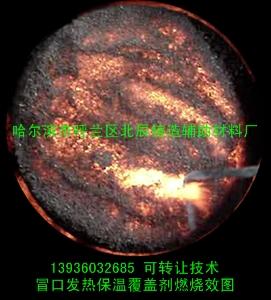

1. It is applicable to the products with heat insulation covering of exposed riser and common riser of sand mold of castings such as alloy steel, high manganese steel, stainless steel, heat-resistant steel, cast steel and cast iron. The product is characterized by long heating time and 30 min heating time. The product immediately burns on the riser, prolongs the setting time of the riser by 4-5 times, and the heating time is about 30min. The surface of the riser shrinks in the shape of (saucer) or (Pan), and does not affect the quality of the original metal.

1. It is applicable to the products with heat insulation covering of exposed riser and common riser of sand mold of castings such as alloy steel, high manganese steel, stainless steel, heat-resistant steel, cast steel and cast iron. The product is characterized by long heating time and 30 min heating time. The product immediately burns on the rise r, prolongs the setting time of the riser by 4-5 times, and the heating time is about 30min. The surface of the riser shrinks in the shape of (saucer) or (Pan), and does not affect the quality of the original metal.

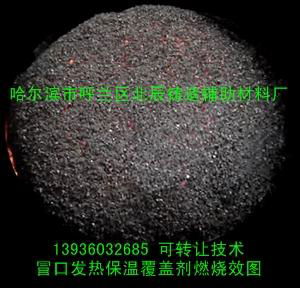

2. When the product does not use the insulating riser sleeve, the riser surface shrinks in the shape of (saucer) or (Pan).

2. When the product does not use the insulating riser sleeve, the riser surface shrinks in the shape of (saucer) or (Pan).

3. Obviously prolonging the time of crusting at the top of riser, making the steel water in riser under the action of atmospheric pressure for a long time, greatly improving the feeding efficiency of riser, benefiting the gas precipitation and the floating of inclusions in the casting, obtaining sound casting and reducing waste products

3. Obviously prolonging the time of crusting at the top of riser, making the steel water in riser under the action of atmospheric pressure for a long time, greatly improving the feeding efficiency of riser, benefiting the gas precipitation and the floating of inclusions in the casting, obtaining sound casting and reducing waste products

2、 Application scope of dfc-600 smokeless riser warming agent:

2、 Application scope of dfc-600 smokeless riser warming agent:

It is suitable for the products with heat insulation covering of open riser and sand mold common riser of castings such as alloy steel, high manganese steel, stainless steel, heat-resistant steel, cast steel, cast iron, etc.

It is suitable for the products with heat insulation covering of open riser and sand mold common riser of castings such as alloy steel, high manganese steel, stainless steel, heat-resistant steel, cast steel, cast iron, etc.

3、 Product performance of dfc-600 smokeless riser heating agent

3、 Product performance of dfc-600 smokeless riser heating agent

This product is suitable for alloy steel, high manganese steel, stainless steel, heat-resistant steel, cast steel, cast iron, etc. In view of the strict environmental protection requirements of manufacturers, the latest product smokeless riser heating agent is developed. In order to avoid the serious carbon increase of the above steel grades, the factory and {Harbin University of technology} jointly developed the heating agent of alloy steel riser, which is also the most ideal product for riser feeding of alloy steel and other steel grades.

This product is suitable for alloy steel, high manganese steel, stainless steel, heat-resistant steel, cast steel, cast iron, etc. In view of the strict environmental protection requirements of manufacturers, the latest product smokeless riser heating agent is developed. In order to avoid the serious carbon increase of the above steel grades, the factory and {Harbin University of technology} jointly developed the heating agent of alloy steel riser, which is also the most ideal product for riser feeding of alloy steel and other steel grades.

4、 Dfc-600 smokeless riser heating agent packaging

4、 Dfc-600 smokeless riser heating agent packaging

Kraft paper with packaging, inner sealed plastic bags. Net weight of each bag 33.4kg 30 bags per ton

Kraft paper with packaging, inner sealed plastic bags. Net weight of each bag 33.4kg 30 bags per ton

5、 Parameters and specifications of dfc-600 smokeless riser heating agent

5、 Parameters and specifications of dfc-600 smokeless riser heating agent

Project: fixed carbon ash volatile water particle size (mesh pH value unit weight

Project: fixed carbon ash volatile water particle size (mesh pH value unit weight

Product ≤ 1 2 10 ≤ 3 ≥ 60 6 0.95-1.05

Product ≤ 1 2 10 ≤ 3 ≥ 60 6 0.95-1.05

/cm

/cm

Low carbon riser heating up covering agent

Low carbon riser heating up covering agent

6、 After sales service of dfc-600 smokeless riser heating agent

6、 After sales service of dfc-600 smokeless riser heating agent

Contact person supporting national delivery: Liu Hailin

Contact person supporting national delivery: Liu Hailin

7、 Working principle of heating agent for dfc-600 smokeless riser

7、 Working principle of heating agent for dfc-600 smokeless riser

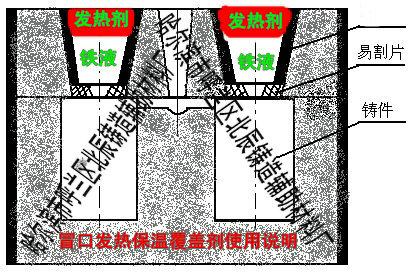

It is suitable for steel casting with riser diameter of 45-1000mm, as well as for covering, heating and heat preservation of molten metal in large ladle and induction furnace.

It is suitable for steel casting with riser diameter of 45-1000mm, as well as for covering, heating and heat preservation of molten metal in large ladle and induction furnace.

After pouring, it shall be placed on the top of riser (i.e. 2 / 3 of riser height), and the thickness is generally 10-15% of riser diameter. Store the product in a dry and ventilated place, pay attention to fire prevention and moisture-proof

After pouring, it shall be placed on the top of riser (i.e. 2 / 3 of riser height), and the thickness is generally 10-15% of riser diameter. Store the product in a dry and ventilated place, pay attention to fire prevention and moisture-proof

Harbin Hulan District Beichen foundry auxiliary material factory

Harbin Hulan District Beichen foundry auxiliary material factory

Address: Jiefang street, Kangjin Town, Hulan District, Harbin

Address: Jiefang street, Kangjin Town, Hulan District, Harbin

| Payment Terms: | Bank remittance to delivery |

|---|---|

Member Information

| Harbin Hulan District Beichen foundry auxiliary material factory | |

|---|---|

| Country/Region: | Hei Long jiang - China |

| Business Nature: | Manufacturer |

| Phone: | 13936032685 |

| Contact: | Hai Lin Liu (manager) |

| Last Online: | 30 Sep, 2022 |