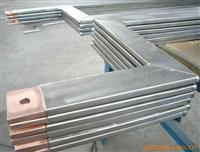

Titanium clad Copper bar(Ti/Cu clad bar), is a major component of a metal anode. It combines copper’s superior conductivity with titanium’s outstanding anticorrosion. It can be applied in Electrolysis, Plating, Hydrometallurgy and Anode Electrobath with a corrosive environment. An excellent choice for electrode! The composite strength of our products can be up to 135Mpa, tensile strength up to 180-260Mpa, which leads to better conductivity. A micro resistance of 7.77X10-6Ω can minimize pollution from electrolyte and plating solution. An energy-saving and environment protective material! We can according to your order, produce clad bars of different shapes(round, barrel, square, flat), and bend, group-weld it as you wish.

FBD supplies the metallurgical bonding clad materials:

Titanium clad Copper and Zirconium clad Copper. The clad materials have both anti-corrosion and high current transfer capabilities. FBD utilizes TiCladCu and ZrCladCu to be the immersion bus bars, which definitely improves the defectives of the conventional bus bar and save 10%~30% energy in plating system.

|

|

Current-transfer under solution result in low potential and high efficiency.

|

|

Non-copper oxide, free maintenance.

|

|

Good for long-term operation. Current supply is stable.

|

|

Non fall-off of deposited impurities and copper oxide cause the easy management solution.

|

|

High current transfer doesn’t cause heat generation to reduce loading of ventilation and cooling systems.

|

|

Open space makes the loading of anode easier and safer.

|

|

|

Current-transfer in the air result in high resistance and potential.

|

|

To clean copper oxide is necessary.

|

|

To clean oxide will shorten copper size to decrease current supply.

|

|

The solution will contaminated by the fall-off of deposited impurities and copper oxide

|

|

High electrical resistance causes heat generation to make loading of ventilation and cooling systems heavier.

|

|

The conventional bus bar interrupts the loading of anode.

|

|