Product overview:

This machine is used for the automated production of multi-layer flat mask finished products. It can use 1 to 4 layers of PP spunbond non-woven activated carbon and filter material. The finished products are all automated in one line, plus two ear band spot welders, which can produce outer ear masks.

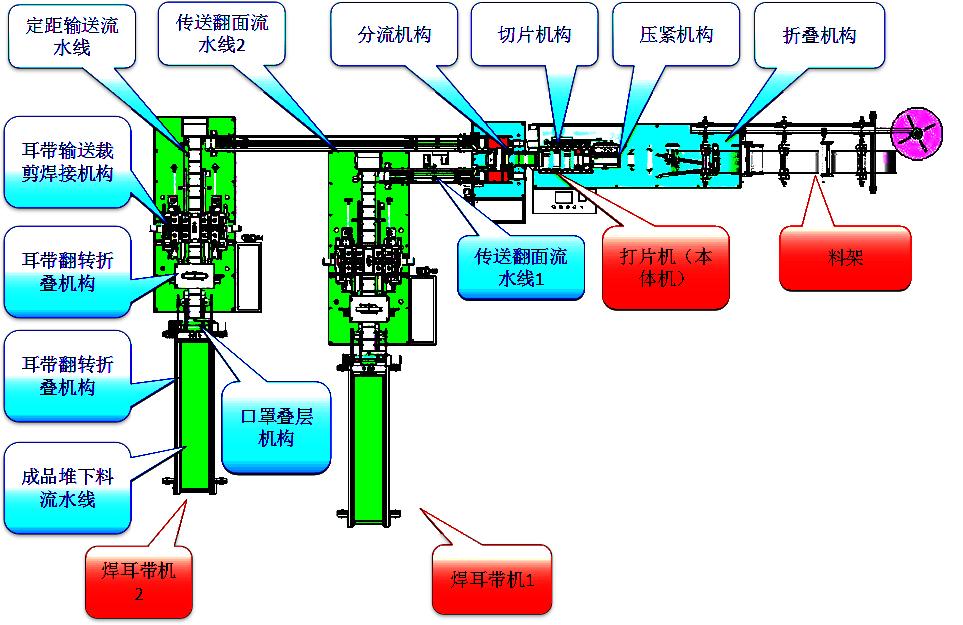

Plane mask one drag two external ear mask machine movement process:

The PP spunbond non-woven fabric incoming roll and nose line roll are manually loaded into the material rack. At first, several layers of non-woven fabric stack and nose line are inserted into the conveying mechanism by artificial heads. The non-woven fabric and the nose line are driven forward by the conveying mechanism, and are folded, compressed, cut and shunted to the two ear band welding machines on the way. Weld the earband through the earmuff welding machine

Features:

The main body adopts high-precision servo motor, which has fast speed, stable movement and high precision. Adjustable level of the picking mechanism. The position mechanism has high versatility and fast product change. The overall equipment adopts a high rigid structure to improve the overall stability of the equipment.

Equipment parameters:

Applicable range of equipment: Flat ear masks with outer ears and masks. Features: The main material transportation uses high-precision servo motors, which are fast, stable and accurate.

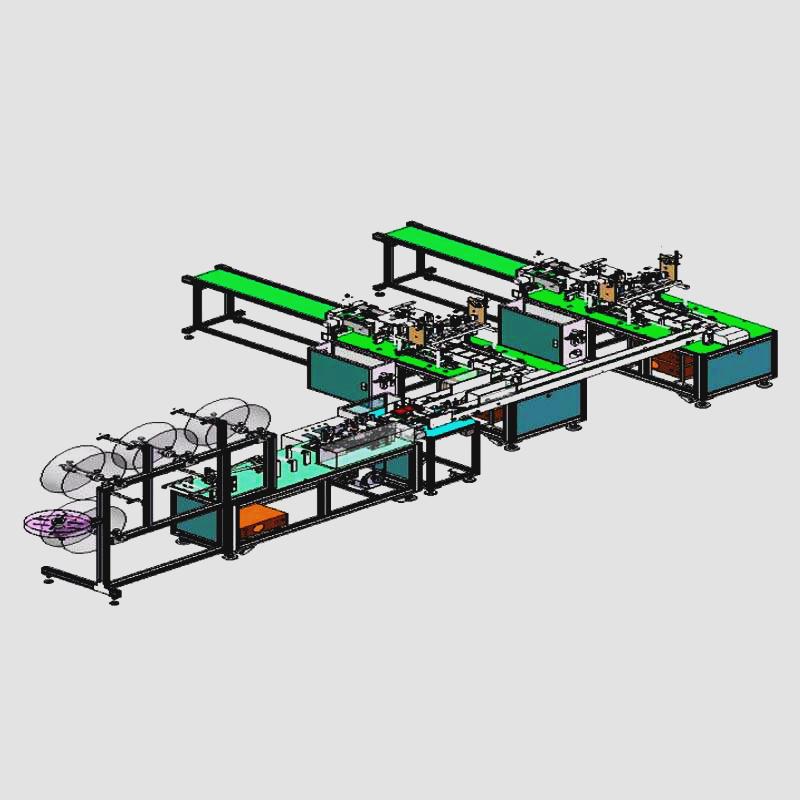

Dimensions Machine length: 6500mm Machine width: 3500 mm Machine height: 1950 mm Adjustable level of the picking mechanism

Operating height Floor to worktable height: 850mm (the height of the assembly line and the feet can be adjusted) The universal mechanism of the whole position is high, and the product is changed quickly

Power supply and power interface Single-phase AC220V / 50HZ / 6000W flat three-pin plug The overall equipment adopts a high rigid structure to improve the overall stability of the equipment.

Working pressure and interface 0.5 ~ 0.7Mpa, dry air source φ12mm quick plug Vacuum Equipped with vacuum pump, can be connected to customer vacuum source <-75KPa, 250L / min

Air consumption 250 L / min Environmental requirements Clean room Class 10 or less

Packing list of equipment:

1 set of universal jigs or 1 set of special jigs

Spare parts Magnetic switches, optical fibers, connectors, etc.

Deb ing Tool Toolbox

1 Allen key

1 set of adjustable wrenches

1 word Seiko transfer approved

1 (for adjusting the magnetic opening of the cylinder)

1 pair of sharp-nosed pliers

1 flat-bladed screwdriver

1 Phillips screwdriver

1 pair of scissors

1 (for cutting foam)