| Model: | S-185S |

|---|---|

| Brand: | KC |

| Origin: | Made In China |

| Category: | Industrial Supplies / Plate Making & Printing Machine |

| Label: | screen printer , silk printer , screen machine |

| Price: |

US $2857

/ pic

|

| Min. Order: | 1 pic |

Product Description

For the printing of cylinders, elliptical cylinders, cones, especially hollow plastic containers, the most preferred choice is the curved surface screen printing machine. The curved surface screen printing machine transfers the left and right movement of the flat screen to the curved surface product through gear transmission or friction transmission. For the printing machinery on the linear contact surface, the continuous rotation of the product, and the part in contact with the surface will continuously receive the ink transfer on the screen to achieve printing.

The significant difference between the curved surface screen printing machine and the flat screen printing machine is that its fixture actually completes the rotation of the product, and the rotation process is in linear contact with the movement of the screen, and no slippage can occur. Therefore, the main elements of the curved screen printing machine are: screen printing screen, screen printing ink, screen printing squeegee, and the squeegee on the curved screen printing machine is usually a squeegee with a triangular cross-section. The screen printing jig has various forms, and its main feature is to ensure the precise and stable rotation of the product.

The curved screen printing machine can print tiny cylinders such as straws and pen refills with a diameter of 1mm, and can also print plastic barrels, oil barrels, and water heater shells with a diameter of more than 500mm. Screens and fixtures will do.

|

S-185S Multi-function cylinder screen printing machine//Structure |

|

|

Working table |

Cylinder workbench/The elliptical cylinder workbench/Flat workbench |

|

Actions |

Up-down of working table |

|

To be printed |

|

|

Squeegee stroke |

Adjust the Limited switch |

|

Squeegee and screen plate control |

High precision guide shaft |

|

S-185S Multi-function screen printing machine//Usage and characters |

|

|

Guide |

|

|

Application |

Plastics soft tubes, Bottles, containers, Bucket, Cosmetic case, any Cylinder-object, Oval-object. |

|

S-185S Multi-function screen printing Machine //Parameters |

|

|

Technical parameters |

|

|

Works supply |

|

|

Package parameters |

|

|

H.S.CODE |

8443198000 |

|

Certificate |

CE |

|

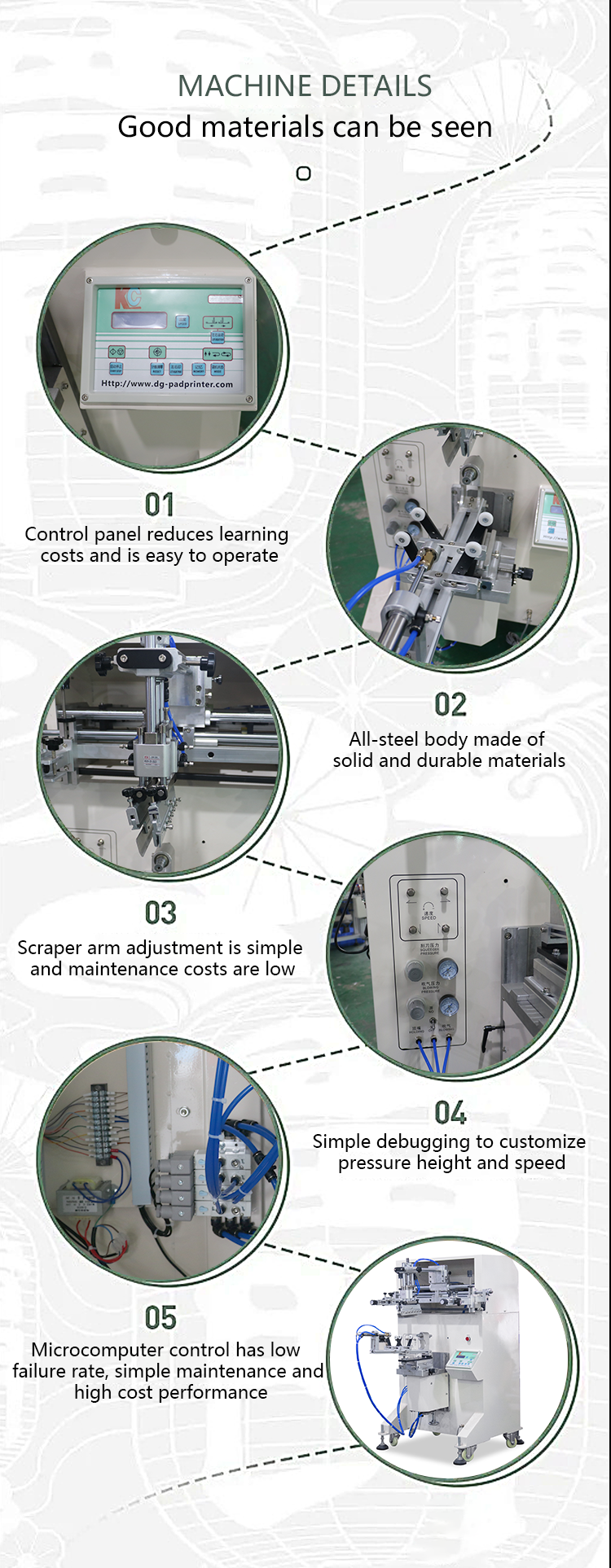

S-185S Multi-function screen printing Machine//Advantage |

|

|

Function |

|

| Application: | For the printing of cylinders, elliptical cylinders, cones, especially hollow plastic containers, the most preferred choice is the curved surface screen printing machine. The curved surface screen printing machine transfers the left and right movement of the flat screen to the curved surface product through gear transmission or friction transmission. For the printing machinery on the linear contact surface, the continuous rotation of the product, and the part in contact with the surface will continuously receive the ink transfer on the screen to achieve printing. The significant difference between the curved surface screen printing machine and the flat screen printing machine is that its fixture actually completes the rotation of the product, and the rotation process is in linear contact with the movement of the screen, and no slippage can occur. Therefore, the main elements of the curved screen printing machine are: screen printing screen, screen printing ink, screen printing squeegee, and the squeegee on the curved screen printing machine is usually a squeegee with a triangular cross-section. The screen printing jig has various forms, and its main feature is to ensure the precise and stable rotation of the product. The curved screen printing machine can print tiny cylinders such as straws and pen refills with a diameter of 1mm, and can also print plastic barrels, oil barrels, and water heater shells with a diameter of more than 500mm. Screens and fixtures will do. |

|---|---|

Member Information

| Dongguan KC Printing Machine Limited | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13592766499 |

| Contact: | Kelven Bai (General manager) |

| Last Online: | 14 Oct, 2024 |

Related Products of this Company

-

Laser phototype-setting machine410FL

US $4846

-

Shopping bags Hydraulic hot stamping

US $12776

-

Automatic Oval bottle cap Golden-line

US $22264

-

High accurate servo shuttle 4-color pad

US $8800

-

Hot selling UV spot vacuum table screen

US $3800

-

Crash can Precision screen printer

US $5500

-

High quality paint bucket heat transfer

US $11000

-

Tabeltop screen printer with robot

US $4700

-

Automatically ribbon Three colors screen

US $35626

-

Flat tabletop screen printer with vacuum

US $1176