| Model: | 5LL400-5LL2000 |

|---|---|

| Brand: | - |

| Origin: | Made In China |

| Category: | Industrial Supplies / Mining Machine |

| Label: | spiral gravity chute , spiral separator , wash plant chrome |

| Price: |

US $1000

/ set

|

| Min. Order: | 1 set |

Product Description

Gravity spiral chute is also called spiral concentrator or gravity separator, it's a kind of gravity concentrator which can separate mineral particles according to density, granularity and shape by the interaction of centrifugal force, friction force of chute surface, water flow pressure and gravity of minerals. Spirals are made of high-density fiberglass, high quality emery and unsaturated resin. It has the advantages of simple and reasonable structure, no moving parts, light weight, small floor area, low price but high separation effect. It is the best roughing gravity equipment, which has been widely used in ferrous and nonferrous metal mines. The spiral chute is suitable for separation of 0.3-0.02mm fine materials such as iron ore, ilmenite ore, chromite ore, pyrite ore, zircon ore, rutile ore, monazite ore, tungsten ore, tin ore, tantalum ore, niobium ore and other materials with enough specific gravity difference.

The gravity spiral chute of larger diameter and pitch should be used for the coarse grain material with a little part of -0.074mm, the spiral chute of smaller and pitch should be used for fine grain material with 60-70% of -0.074mm. The spiral chute is usually used in combination of multiple units, such as 4 units for a group, 8 units for a group or 12 units for a group, etc. Multiple units can be combined into a large cluster, which can theoretically form an infinite capacity spiral concentrator processing plant.

Advantages and features

1. Low price, long service life, low operating cost, low investment and quick revenue;

2. Light weight, easy installation, small floor area, save foundation construction investment;

3. Moisture-proof, rust-proof, wear-resistant and corrosion resistant;

4. Water and power saving, simple operation, no moving parts, no maintenance;

5. The separating process is stable and easy to control;

6. Strong adaptability of feeding amount, concentration, particle size and grade. High enrichment ratio and high recovery rate;

7. The special friction force formed on the emery surface makes the separation effect better than other plastic surfaces.

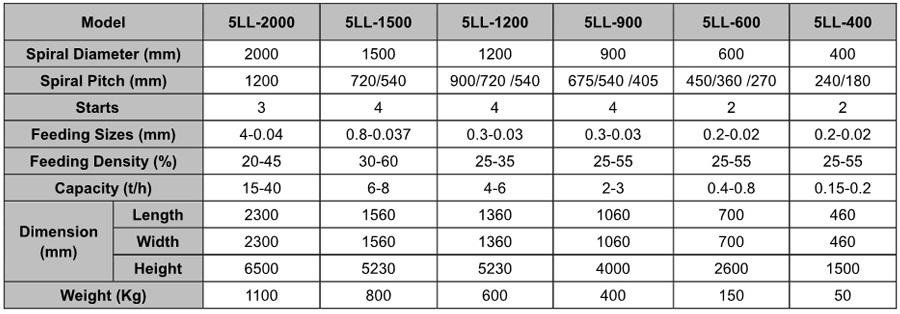

Main Technical Parameters

|

Model |

5LL-2000 |

5LL-1500 |

5LL-1200 |

5LL-900 |

5LL-600 |

5LL-400 |

|

|

Spiral Diameter (mm) |

2000 |

1500 |

1200 |

900 |

600 |

400 |

|

|

Spiral Pitch (mm) |

1200 |

720/540 |

900/720/540 |

675/540/405 |

450/360/270 |

240/180 |

|

|

Starts |

3 |

4 |

4 |

4 |

2 |

2 |

|

|

Feeding Sizes (mm) |

4-0.04 |

0.8-0.037 |

0.3-0.03 |

0.3-0.03 |

0.2-0.02 |

0.2-0.02 |

|

|

Feeding Density (%) |

20-45 |

30-60 |

25-35 |

25-55 |

25-55 |

25-55 |

|

|

Capacity (t/h) |

15-40 |

6-8 |

4-6 |

2-3 |

0.4-0.8 |

0.15-0.2 |

|

|

Dimension

|

Length |

2300 |

1560 |

1360 |

1060 |

700 |

460 |

|

Width |

2300 |

1560 |

1360 |

1060 |

700 |

460 |

|

|

Height |

6500 |

5230 |

5230 |

4000 |

2600 |

1500 |

|

|

Weight (Kg) |

1100 |

800 |

600 |

400 |

150 |

50 |

|

Member Information

| YEES Mining Equipment Co., Ltd. | |

|---|---|

| Country/Region: | Jiang Xi - China |

| Business Nature: | Manufacturer |

| Phone: | 15970053162 |

| Contact: | Grace Chen (Sales) |

| Last Online: | 05 Aug, 2020 |

Related Products of this Company

-

Jig Mining Machine Gold Jig Concentrator

-

Gold Shaker Table for Sale

US $1000

-

Linear Motion Vibrating Screen for Sale

-

Diamond Gold Mining Washing Plant

US $2000

-

Fine Gold Recovery Equipment Centrifugal

US $8000

-

Gold Ore Wash Trommel Screen

US $5000

-

Alluvial Gold Mining Equipment Mobile

US $10000

-

Wet Ball Mill Machine for Sale

US $5000

-

Alluvial Gold Mining Equipment Mobile

US $10000

-

Multi Deck Circular Motion Vibrating