| Model: | Electrical Pure |

|---|---|

| Brand: | Electrical Pure Iron Rods Bars Strips |

| Origin: | Made In Taiwan, China |

| Category: | Electronics & Electricity / Electronic Components / Other Electronic Components |

| Label: | DT4 DT4C Rods Bars , DT4 DT4C Strips Wire , YT01 Rod Bar Strip |

| Price: |

-

|

| Min. Order: | - |

Product Description

Electrical Pure Iron Rods Bars Strips

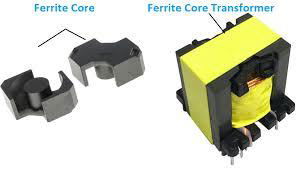

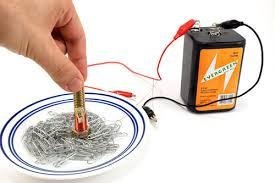

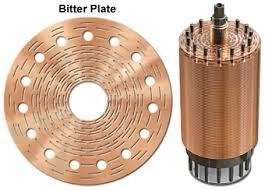

We are Stockholder, Distributors & Manufacture of Electrical Pure Iron, Soft Electrolytic Iron, Soft Electromagnetic Iron, Soft Magnetic Iron, Soft Electro Magnetic Iron, Soft Iron, Soft Magnet Iron, Soft Magnetic Steel, Electromagnetic Steel, Electrotechnical Quality Unalloyed Steel, Low-Carbon Magnetically Soft Steel, Soft Pure Low Carbon Iron in Grades DT4, DT4A, DT4E, DT4C, YT01, YT0, YT2, YT3, DT8, DT8A, DT8E, DT8C, DT9 in the form of Sheets, Plates, Strips, Bars, Rods, Round Bars, Tubes, Pipes, Hollow Tubes, Hollow Pipes, Hollow Bars, Drawn Bars, Cold Drawn Bars, Hot Rolled Bars, Forged Bars, Blocks, Disc, Circle, Shapes, Wires, Coils, Fittings, Forgings, Castings, Machined Parts, Flanges, Nuts, Bolts, Studs, Gaskets, Washers, Machined Components mainly used for Axial Flux Motors, Electric Motors, Generators, Transformers, Solenoid, Relay, Cores, Inductors, Linear Actuation, Rotational Actuation, Magnetic Coils, Sensor Sytems, Magnets, Yoke, Armature, Laminations, Flux Cencentrator, Magnetic Shields, Relay Components, Toroidal Core, Energy Meters, Automotive Shunt, DC Electromagnets

Electrical Pure Iron Grade DT4, DT4A, DT4E, DT4C Rods, Bars, Strips, Wires, Sheets, Plates

Electrical Pure Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rods, Bars, Strips, Wires, Sheets, Plates

Electrical Pure Iron Grade YT01, YT0, YT2, YT3 Rods, Bars, Strips, Wires, Sheets, Plates

Pure Iron Grade DT4, DT4A, DT4E, DT4C Rod, Bar, Strip, Wire, Sheet, Plate

Pure Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rod, Bar, Strip, Wire, Sheet, Plate

Pure Iron Grade YT01, YT0, YT2, YT3 Rod, Bar, Strip, Wire, Sheet, Plate

Soft Iron Grade DT4, DT4A, DT4E, DT4C Rods, Bars, Strips, Wires, Sheets, Plates

Soft Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rods, Bars, Strips, Wires, Sheets, Plates

Soft Iron Grade YT01, YT0, YT2, YT3 Rods, Bars, Strips, Wires, Sheets, Plates

Soft Magnetic Iron Grade DT4, DT4A, DT4E, DT4C Rod, Bar, Strip, Wire, Sheet, Plate

Soft Magnetic Grade DT8, DT8A, DT8E, DT8C, DT9 Rod, Bar, Strip, Wire, Sheet, Plate

Soft Magnetic Iron Grade YT01, YT0, YT2, YT3 Rod, Bar, Strip, Wire, Sheet, Plate

Low Carbon Pure Iron Grade DT4, DT4A, DT4E, DT4C Rods, Bars, Strips, Wires, Sheets, Plates

Low Carbon Pure Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rods, Bars, Strips, Wires, Sheets, Plates

Low Carbon Pure Iron Grade YT01, YT0, YT2, YT3 Rods, Bars, Strips, Wires, Sheets, Plates

Low-Carbon Soft-Iron Grade DT4, DT4A, DT4E, DT4C Rod, Bar, Strip, Wire, Sheet, Plate

Low-Carbon Soft-Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rod, Bar, Strip, Wire, Sheet, Plate

Low-Carbon Soft-Iron Grade YT01, YT0, YT2, YT3 Rod, Bar, Strip, Wire, Sheet, Plate

Electromagnetic Iron Grade DT4, DT4A, DT4E, DT4C Rods, Bars, Strips, Wires, Sheets, Plates

Electromagnetic Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rods, Bars, Strips, Wires, Sheets, Plates

Electromagnetic Iron Grade YT01, YT0, YT2, YT3 Rods, Bars, Strips, Wires, Sheets, Plates

Electro-magnetic Iron Grade DT4, DT4A, DT4E, DT4C Rod, Bar, Strip, Wire, Sheet, Plate

Electro-magnetic Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rod, Bar, Strip, Wire, Sheet, Plate

Electro-magnetic Iron Grade YT01, YT0, YT2, YT3 Rod, Bar, Strip, Wire, Sheet, Plate

Electromagnetic Steel Grade DT4, DT4A, DT4E, DT4C Rods, Bars, Strips, Wires, Sheets, Plates

Electromagnetic Steel Grade DT8, DT8A, DT8E, DT8C, DT9 Rods, Bars, Strips, Wires, Sheets, Plates

Electromagnetic Steel Grade YT01, YT0, YT2, YT3 Rods, Bars, Strips, Wires, Sheets, Plates

Electro-magnetic Steel Grade DT4, DT4A, DT4E, DT4C Rod, Bar, Strip, Wire, Sheet, Plate

Electro-magnetic Steel Grade DT8, DT8A, DT8E, DT8C, DT9 Rod, Bar, Strip, Wire, Sheet, Plate

Electro-magnetic Steel Grade YT01, YT0, YT2, YT3 Rod, Bar, Strip, Wire, Sheet, Plate

Soft Pure Low Carbon Iron Grade DT4, DT4A, DT4E, DT4C Rods, Bars, Strips, Wires, Sheets, Plates

Soft Pure Low Carbon Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rods, Bars, Strips, Wires, Sheets, Plates

Soft Pure Low Carbon Iron Grade YT01, YT0, YT2, YT3 Rods, Bars, Strips, Wires, Sheets, Plates

Soft Pure Low-Carbon Iron Grade DT4, DT4A, DT4E, DT4C Rod, Bar, Strip, Wire, Sheet, Plate

Soft Pure Low-Carbon Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rod, Bar, Strip, Wire, Sheet, Plate

Soft Pure Low-Carbon Iron Grade YT01, YT0, YT2, YT3 Rod, Bar, Strip, Wire, Sheet, Plate

Manufacture of Electrical Pure Iron Grade DT4, DT4A, DT4E, DT4C Rods, Bars, Strips, Wires, Sheets, Plates

Manufacture of Electrical Pure Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rods, Bars, Strips, Wires, Sheets, Plates

Manufacture of Electrical Pure Iron Grade YT01, YT0, YT2, YT3 Rods, Bars, Strips, Wires, Sheets, Plates

Manufacture of Pure Iron Grade DT4, DT4A, DT4E, DT4C Rod, Bar, Strip, Wire, Sheet, Plate

Manufacture of Pure Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rod, Bar, Strip, Wire, Sheet, Plate

Manufacture of Pure Iron Grade YT01, YT0, YT2, YT3 Rod, Bar, Strip, Wire, Sheet, Plate

Manufacture of Soft Iron Grade DT4, DT4A, DT4E, DT4C Rods, Bars, Strips, Wires, Sheets, Plates

Manufacture of Soft Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rods, Bars, Strips, Wires, Sheets, Plates

Manufacture of Soft Iron Grade YT01, YT0, YT2, YT3 Rods, Bars, Strips, Wires, Sheets, Plates

Manufacture of Soft Magnetic Iron Grade DT4, DT4A, DT4E, DT4C Rod, Bar, Strip, Wire, Sheet, Plate

Manufacture of Soft Magnetic Grade DT8, DT8A, DT8E, DT8C, DT9 Rod, Bar, Strip, Wire, Sheet, Plate

Manufacture of Soft Magnetic Iron Grade YT01, YT0, YT2, YT3 Rod, Bar, Strip, Wire, Sheet, Plate

Manufacture of Low Carbon Pure Iron Grade DT4, DT4A, DT4E, DT4C Rods, Bars, Strips, Wires, Sheets, Plates

Manufacture of Low Carbon Pure Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rods, Bars, Strips, Wires, Sheets, Plates

Manufacture of Low Carbon Pure Iron Grade YT01, YT0, YT2, YT3 Rods, Bars, Strips, Wires, Sheets, Plates

Manufacture of Low-Carbon Soft-Iron Grade DT4, DT4A, DT4E, DT4C Rod, Bar, Strip, Wire, Sheet, Plate

Manufacture of Low-Carbon Soft-Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rod, Bar, Strip, Wire, Sheet, Plate

Manufacture of Low-Carbon Soft-Iron Grade YT01, YT0, YT2, YT3 Rod, Bar, Strip, Wire, Sheet, Plate

Manufacture of Electromagnetic Iron Grade DT4, DT4A, DT4E, DT4C Rods, Bars, Strips, Wires, Sheets, Plates

Manufacture of Electromagnetic Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rods, Bars, Strips, Wires, Sheets, Plates

Manufacture of Electromagnetic Iron Grade YT01, YT0, YT2, YT3 Rods, Bars, Strips, Wires, Sheets, Plates

Manufacture of Electro-magnetic Iron Grade DT4, DT4A, DT4E, DT4C Rod, Bar, Strip, Wire, Sheet, Plate

Manufacture of Electro-magnetic Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rod, Bar, Strip, Wire, Sheet, Plate

Manufacture of Electro-magnetic Iron Grade YT01, YT0, YT2, YT3 Rod, Bar, Strip, Wire, Sheet, Plate

Manufacture of Electromagnetic Steel Grade DT4, DT4A, DT4E, DT4C Rods, Bars, Strips, Wires, Sheets, Plates

Manufacture of Electromagnetic Steel Grade DT8, DT8A, DT8E, DT8C, DT9 Rods, Bars, Strips, Wires, Sheets, Plates

Manufacture of Electromagnetic Steel Grade YT01, YT0, YT2, YT3 Rods, Bars, Strips, Wires, Sheets, Plates

Manufacture of Electro-magnetic Steel Grade DT4, DT4A, DT4E, DT4C Rod, Bar, Strip, Wire, Sheet, Plate

Manufacture of Electro-magnetic Steel Grade DT8, DT8A, DT8E, DT8C, DT9 Rod, Bar, Strip, Wire, Sheet, Plate

Manufacture of Electro-magnetic Steel Grade YT01, YT0, YT2, YT3 Rod, Bar, Strip, Wire, Sheet, Plate

Manufacture of Soft Pure Low Carbon Iron Grade DT4, DT4A, DT4E, DT4C Rods, Bars, Strips, Wires, Sheets, Plates

Manufacture of Soft Pure Low Carbon Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rods, Bars, Strips, Wires, Sheets, Plates

Manufacture of Soft Pure Low Carbon Iron Grade YT01, YT0, YT2, YT3 Rods, Bars, Strips, Wires, Sheets, Plates

Manufacture of Soft Pure Low-Carbon Iron Grade DT4, DT4A, DT4E, DT4C Rod, Bar, Strip, Wire, Sheet, Plate

Manufacture of Soft Pure Low-Carbon Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rod, Bar, Strip, Wire, Sheet, Plate

Manufacture of Soft Pure Low-Carbon Iron Grade YT01, YT0, YT2, YT3 Rod, Bar, Strip, Wire, Sheet, Plate

Stockholder of Electrical Pure Iron Grade DT4, DT4A, DT4E, DT4C Rods, Bars, Strips, Wires, Sheets, Plates

Stockholder of Electrical Pure Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rods, Bars, Strips, Wires, Sheets, Plates

Stockholder of Electrical Pure Iron Grade YT01, YT0, YT2, YT3 Rods, Bars, Strips, Wires, Sheets, Plates

Stockholder of Pure Iron Grade DT4, DT4A, DT4E, DT4C Rod, Bar, Strip, Wire, Sheet, Plate

Stockholder of Pure Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rod, Bar, Strip, Wire, Sheet, Plate

Stockholder of Pure Iron Grade YT01, YT0, YT2, YT3 Rod, Bar, Strip, Wire, Sheet, Plate

Stockholder of Soft Iron Grade DT4, DT4A, DT4E, DT4C Rods, Bars, Strips, Wires, Sheets, Plates

Stockholder of Soft Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rods, Bars, Strips, Wires, Sheets, Plates

Stockholder of Soft Iron Grade YT01, YT0, YT2, YT3 Rods, Bars, Strips, Wires, Sheets, Plates

Stockholder of Soft Magnetic Iron Grade DT4, DT4A, DT4E, DT4C Rod, Bar, Strip, Wire, Sheet, Plate

Stockholder of Soft Magnetic Grade DT8, DT8A, DT8E, DT8C, DT9 Rod, Bar, Strip, Wire, Sheet, Plate

Stockholder of Soft Magnetic Iron Grade YT01, YT0, YT2, YT3 Rod, Bar, Strip, Wire, Sheet, Plate

Stockholder of Low Carbon Pure Iron Grade DT4, DT4A, DT4E, DT4C Rods, Bars, Strips, Wires, Sheets, Plates

Stockholder of Low Carbon Pure Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rods, Bars, Strips, Wires, Sheets, Plates

Stockholder of Low Carbon Pure Iron Grade YT01, YT0, YT2, YT3 Rods, Bars, Strips, Wires, Sheets, Plates

Stockholder of Low-Carbon Soft-Iron Grade DT4, DT4A, DT4E, DT4C Rod, Bar, Strip, Wire, Sheet, Plate

Stockholder of Low-Carbon Soft-Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rod, Bar, Strip, Wire, Sheet, Plate

Stockholder of Low-Carbon Soft-Iron Grade YT01, YT0, YT2, YT3 Rod, Bar, Strip, Wire, Sheet, Plate

Stockholder of Electromagnetic Iron Grade DT4, DT4A, DT4E, DT4C Rods, Bars, Strips, Wires, Sheets, Plates

Stockholder of Electromagnetic Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rods, Bars, Strips, Wires, Sheets, Plates

Stockholder of Electromagnetic Iron Grade YT01, YT0, YT2, YT3 Rods, Bars, Strips, Wires, Sheets, Plates

Stockholder of Electro-magnetic Iron Grade DT4, DT4A, DT4E, DT4C Rod, Bar, Strip, Wire, Sheet, Plate

Stockholder of Electro-magnetic Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rod, Bar, Strip, Wire, Sheet, Plate

Stockholder of Electro-magnetic Iron Grade YT01, YT0, YT2, YT3 Rod, Bar, Strip, Wire, Sheet, Plate

Stockholder of Electromagnetic Steel Grade DT4, DT4A, DT4E, DT4C Rods, Bars, Strips, Wires, Sheets, Plates

Stockholder of Electromagnetic Steel Grade DT8, DT8A, DT8E, DT8C, DT9 Rods, Bars, Strips, Wires, Sheets, Plates

Stockholder of Electromagnetic Steel Grade YT01, YT0, YT2, YT3 Rods, Bars, Strips, Wires, Sheets, Plates

Stockholder of Electro-magnetic Steel Grade DT4, DT4A, DT4E, DT4C Rod, Bar, Strip, Wire, Sheet, Plate

Stockholder of Electro-magnetic Steel Grade DT8, DT8A, DT8E, DT8C, DT9 Rod, Bar, Strip, Wire, Sheet, Plate

Stockholder of Electro-magnetic Steel Grade YT01, YT0, YT2, YT3 Rod, Bar, Strip, Wire, Sheet, Plate

Stockholder of Soft Pure Low Carbon Iron Grade DT4, DT4A, DT4E, DT4C Rods, Bars, Strips, Wires, Sheets, Plates

Stockholder of Soft Pure Low Carbon Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rods, Bars, Strips, Wires, Sheets, Plates

Stockholder of Soft Pure Low Carbon Iron Grade YT01, YT0, YT2, YT3 Rods, Bars, Strips, Wires, Sheets, Plates

Stockholder of Soft Pure Low-Carbon Iron Grade DT4, DT4A, DT4E, DT4C Rod, Bar, Strip, Wire, Sheet, Plate

Stockholder of Soft Pure Low-Carbon Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rod, Bar, Strip, Wire, Sheet, Plate

Stockholder of Soft Pure Low-Carbon Iron Grade YT01, YT0, YT2, YT3 Rod, Bar, Strip, Wire, Sheet, Plate

Distributors of Electrical Pure Iron Grade DT4, DT4A, DT4E, DT4C Rods, Bars, Strips, Wires, Sheets, Plates

Distributors of Electrical Pure Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rods, Bars, Strips, Wires, Sheets, Plates

Distributors of Electrical Pure Iron Grade YT01, YT0, YT2, YT3 Rods, Bars, Strips, Wires, Sheets, Plates

Distributors of Pure Iron Grade DT4, DT4A, DT4E, DT4C Rod, Bar, Strip, Wire, Sheet, Plate

Distributors of Pure Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rod, Bar, Strip, Wire, Sheet, Plate

Distributors of Pure Iron Grade YT01, YT0, YT2, YT3 Rod, Bar, Strip, Wire, Sheet, Plate

Distributors of Soft Iron Grade DT4, DT4A, DT4E, DT4C Rods, Bars, Strips, Wires, Sheets, Plates

Distributors of Soft Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rods, Bars, Strips, Wires, Sheets, Plates

Distributors of Soft Iron Grade YT01, YT0, YT2, YT3 Rods, Bars, Strips, Wires, Sheets, Plates

Distributors of Soft Magnetic Iron Grade DT4, DT4A, DT4E, DT4C Rod, Bar, Strip, Wire, Sheet, Plate

Distributors of Soft Magnetic Grade DT8, DT8A, DT8E, DT8C, DT9 Rod, Bar, Strip, Wire, Sheet, Plate

Distributors of Soft Magnetic Iron Grade YT01, YT0, YT2, YT3 Rod, Bar, Strip, Wire, Sheet, Plate

Distributors of Low Carbon Pure Iron Grade DT4, DT4A, DT4E, DT4C Rods, Bars, Strips, Wires, Sheets, Plates

Distributors of Low Carbon Pure Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rods, Bars, Strips, Wires, Sheets, Plates

Distributors of Low Carbon Pure Iron Grade YT01, YT0, YT2, YT3 Rods, Bars, Strips, Wires, Sheets, Plates

Distributors of Low-Carbon Soft-Iron Grade DT4, DT4A, DT4E, DT4C Rod, Bar, Strip, Wire, Sheet, Plate

Distributors of Low-Carbon Soft-Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rod, Bar, Strip, Wire, Sheet, Plate

Distributors of Low-Carbon Soft-Iron Grade YT01, YT0, YT2, YT3 Rod, Bar, Strip, Wire, Sheet, Plate

Distributors of Electromagnetic Iron Grade DT4, DT4A, DT4E, DT4C Rods, Bars, Strips, Wires, Sheets, Plates

Distributors of Electromagnetic Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rods, Bars, Strips, Wires, Sheets, Plates

Distributors of Electromagnetic Iron Grade YT01, YT0, YT2, YT3 Rods, Bars, Strips, Wires, Sheets, Plates

Distributors of Electro-magnetic Iron Grade DT4, DT4A, DT4E, DT4C Rod, Bar, Strip, Wire, Sheet, Plate

Distributors of Electro-magnetic Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rod, Bar, Strip, Wire, Sheet, Plate

Distributors of Electro-magnetic Iron Grade YT01, YT0, YT2, YT3 Rod, Bar, Strip, Wire, Sheet, Plate

Distributors of Electromagnetic Steel Grade DT4, DT4A, DT4E, DT4C Rods, Bars, Strips, Wires, Sheets, Plates

Distributors of Electromagnetic Steel Grade DT8, DT8A, DT8E, DT8C, DT9 Rods, Bars, Strips, Wires, Sheets, Plates

Distributors of Electromagnetic Steel Grade YT01, YT0, YT2, YT3 Rods, Bars, Strips, Wires, Sheets, Plates

Distributors of Electro-magnetic Steel Grade DT4, DT4A, DT4E, DT4C Rod, Bar, Strip, Wire, Sheet, Plate

Distributors of Electro-magnetic Steel Grade DT8, DT8A, DT8E, DT8C, DT9 Rod, Bar, Strip, Wire, Sheet, Plate

Distributors of Electro-magnetic Steel Grade YT01, YT0, YT2, YT3 Rod, Bar, Strip, Wire, Sheet, Plate

Distributors of Soft Pure Low Carbon Iron Grade DT4, DT4A, DT4E, DT4C Rods, Bars, Strips, Wires, Sheets, Plates

Distributors of Soft Pure Low Carbon Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rods, Bars, Strips, Wires, Sheets, Plates

Distributors of Soft Pure Low Carbon Iron Grade YT01, YT0, YT2, YT3 Rods, Bars, Strips, Wires, Sheets, Plates

Distributors of Soft Pure Low-Carbon Iron Grade DT4, DT4A, DT4E, DT4C Rod, Bar, Strip, Wire, Sheet, Plate

Distributors of Soft Pure Low-Carbon Iron Grade DT8, DT8A, DT8E, DT8C, DT9 Rod, Bar, Strip, Wire, Sheet, Plate

Distributors of Soft Pure Low-Carbon Iron Grade YT01, YT0, YT2, YT3 Rod, Bar, Strip, Wire, Sheet, Plate

Electromagnetic pure iron is a type of high quality steel containing over 99.5% of iron with quite low

content of remained elements and featuring with soft texture, strong toughness, easy process and

high electromagnetic performance. Based on its magnetic property, the electromagnetic pure iron

can be classified into three grades: DT4A, DT4E and DT4C. Based on various applications, the

electromagnetic pure iron can be classified into iron core purpose, soft magnetic purpose,

electronic lock purpose, space instruments and military purpose, electron tube purpose and

easy turning electrical purpose.

Electromagnetic pure iron was applied to not only the cutting-edge engineering of national defense

work, but also industrial fields such as relays, instruments and direct current motors. wire and rod

products were mainly used to the civil industry, take the absolute advantage at middle and high-end

and keep growing stably. In recent years, depending on the customer's requirements, newly

developed ultra-low coercive force electromagnetic pure iron featuring more stable magnetism,

better processing property and lower cost which has been widely used to work and life necessities

in the fields of medical imaging, superconducting power generation and strong/weak magnetic field

shielding of the communication devices.

High-purity iron with purity of 99.987 wt.% was prepared employing a process of direct reduction–melting

separation–slag refining. The iron ore after pelletizing and roasting was reduced by hydrogen to obtain

direct reduced iron (DRI). Carbon and sulfur were removed in this step and other impurities such as

silicon, manganese, titanium and aluminum were excluded from metallic iron. Dephosphorization was

implemented simultaneously during the melting separation step by making use of the ferrous oxide (FeO)

contained in DRI. The problem of deoxidization for pure iron was solved, and the oxygen content of pure

iron was reduced to 10 ppm by refining with a high basicity slag. Compared with electrolytic iron, the pure

iron prepared by this method has tremendous advantages in cost and scale and has more outstanding

quality than technically pure iron, making it possible to produce high-purity iron in a short-flow, large-scale,

low-cost and environmentally friendly way.

We can produce the special type which you ask Applications High purity iron is used largely as the basic

material for (re-)melting of low-carbon, Stainless and acid-resistant steels, materials with a high nickel content,

magnetic alloys as well as stainless and heat resistant steel castings in induction and vacuum furnaces. High

purity iron is also used in many applications of aviation construction, nuclear Technology, the production of

magnets (pole cores, yokes and armatures), in automotive construction, as magnetic shielding, as welding

rods and fuse wire, as gasket in the chemical and petrochemical industry, power station construction, as

anti-corrosion anode and as galvanizing tank including equipment. Mechanical properties Brinell hardness (hb)

High purity iron Max. Typical Cold-rolled strip / sheet 105 90 Hot-rolled strip / plate 105 90 Quarto plate 100 90

Round bar 110 95 Electrical and magnetic properties Characteristics typical values Initial permeability 300 – 500

Permeability 3500 - 6000 Coercive force 60 – 120 a/m Saturation induction 2.15 t Density at 20 °c 7.86 kg/dm³

Melting point 1536 °c Linear expansion coefficient Temperature range 0 – 100 °c 12x10-6 1/°c Modulus of

elasticity 207 kn/mm²

Pure iron, which refers to iron with very few impurities, has excellent properties such as low coercivity,

high ductility, soft texture as well as good performance in thermal conductivity and electrical conductivity.

High-purity iron is widely used in aerospace, radio engineering, the atomic industry and other fields.

It is an important raw material for the production of precision alloys, superalloys, advanced heat-resistant

alloys, amorphous alloys, soft magnetic materials, permanent magnet alloys and other materials. In recent

years, pure iron has been paid more and more attention due to its extensive use and high added-value.

Pure iron is generally categorized as electrolytic iron and technically pure iron. Electrolytic iron can be

prepared by electrolytic refining of high purity ferrous salt solution obtained by ion exchange or solvent

extraction. The purity of a conventional electrolytic iron is about 99.9 wt.%, containing gaseous impurities

such as carbon, nitrogen, oxygen, hydrogen, sulfur and chlorine of more than 500 mass ppm in total.

To obtain higher-purity products, zone refining, electromagnetic levitation melting and vacuum induction

melting are used to further purify electrolytic iron. Since a single purification method cannot meet the

requirements of preparing ultra-high-purity iron, it is necessary to combine various purification methods.

The common process is ion exchange + solvent extraction → electrolytic refining → cold-crucible

melting → zone refining. Many efforts have been devoted to the preparation of high-purity iron.

succeeded in making ultra-high-purity iron of 99.999 wt.% from pure iron by electron beam zone refining

in an atmosphere of ultra-high vacuum. et al. [3–5] made a 7.5 kg ultra-high-purity iron ingot by

careful refining of high purity electrolytic iron. The purity of the purified iron was determined to be

99.9988 wt.% by chemical analysis of 33 elements. et al. [6] developed a process consisting of anion

exchange in a HCl solution, hydrogen reduction and plasma arc melting for the production of semiconductor

grade high-purity Fe with 99.998 wt.% purity. After improving the refining efficiency, the purity of Fe

achieved 99.9993 wt.%

At present, the pure iron that has been produced and applied industrially is called technically pure iron,

with purity ranging from 99.6% to 99.8%. As a raw material for smelting various special alloys such as

superalloys, heat-resistant alloys, precision alloys and maraging steel, technically pure iron has been

widely used in metallurgical industry. Technically pure iron is produced by pyrometallurgy. Firstly, iron

ore is reduced to pig iron in a blast furnace, then excessive carbon is removed by the basic oxygen

furnace (BOF) or electric arc furnace (EAF), and impurities are further eliminated via a secondary refining

route, through which the required purity level is achieved.

During the past few years, the demands for high-quality materials have grown more and more. Some alloys

(e.g., heat-resistant alloys) use technically pure iron in smelting raw materials, but the impurities such as

oxygen, phosphorus and sulfur in technically pure iron are not invariably low. These impurities cannot be

eliminated readily during the alloy smelting process, leading to the situation that the alloy cannot achieve the

desired performance [8]. The quality improvement of technically pure iron produced by hot metal from a

blast furnace is hindered by impurity elements. Besides removing the impurities such as silicon, manganese

and phosphorus, oxygen is injected to remove excess carbon in hot metal. Blowing oxygen causes an

excess of oxygen to be brought into the hot metal, after which it is necessary to add aluminum or strictly

control the C–O reaction using a vacuum for further deoxidation. This lengthy and complicated process,

which revolves around decarbonization and deoxidation, violates the original intention of purification and

makes it difficult to produce pure iron with high cleanliness. On the other hand, the concentrations of gas

impurities (C+N+H+O+S) in common commercial electrolytic iron are generally high. Further refining would

increase the cost and make it difficult to achieve an efficient production. The high-purity iron or ultra-high-purity

iron with 99.99–99.999% purity is too expensive ($7000–200,000 US dollars/tonne) to be used on a large scale.

Research and development of high-purity iron is still in the small-scale laboratory stage, and the supply cannot

meet the demand. Therefore, the manufacture of pure iron has great market potential and profit margin.

How to use short-process, low-cost and environmentally friendly manufacturing technology to produce

high-quality pure iron is the future direction of research.

In this study, an approach of producing high-purity iron is proposed via a direct reduction of iron ore–melting

separation–refining process, by which high-purity iron with purity up to 99.987% can be produced on a large

scale with low cost. The process mainly includes three major steps: Step 1, the iron ore after pelletizing and

roasting is reduced by hydrogen, and direct reduced iron (DRI) that is carbon-free is obtained. Some impurities

such as carbon, sulfur, silicon, manganese, titanium and aluminum cannot be reduced or get into iron in this

step. Step 2, the direct reduced iron is separated into gangue (slag) and metal by melting. In this step, the

composition of slag is adjusted to dephosphorize, if necessary. Step 3, the high basicity slag is dosed to

refining for deoxidation. Similar to the process investigated in this study, researchers have studied the process

of smelting pure iron with DRI in an induction furnace, which has delivered good results. However, these results

still have the capacity to improve the impurities removal in pure iron, especially in solving the problem of

deoxidation of pure iron, so the purity has not reached a high grade. As a comparison, the chemical compositions

of pure iron in this work, typical technically pure iron and typical commercial electrolytic iron, are shown in Table 1.

The purity of pure iron produced by the process has exceeded that of commercial electrolytic iron and technically

pure iron. When the purity of pure iron reaches 3N level or above, it is very difficult to further improve the purity,

and the increase of cost and price brought by this is an exponential growth. The pure iron obtained by this method

has tremendous advantages in cost and scale compared with electrolytic iron and has more outstanding quality

than technically pure iron. This is because this process takes full advantage of the purity advantage of DRI and

solves the problem of deoxidization of pure iron in the context of large-scale production. This paper mainly

expounds upon the experimental process and related mechanism of producing high-purity iron by this method,

as well as the feasibility of industrialization.

Table 1. The chemical compositions of pure iron in this work, typical technically pure iron and typical commercial electrolytic iron (wt.%).

Element Pure Iron in This Work Typical Technically Pure Iron Typical Commercial Electrolytic Iron

C 0.0024 0.0030 0.0057

Si 0.0011 0.0100 0.0030

Mn 0.0003 0.0400 0.0003

P 0.0018 0.0021 0.0005

S 0.0005 0.0016 0.0018

Cr 0.0009 0.0100 0.0003

Ni 0.0005 0.0100 0.0032

Al 0.0015 0.0150 0.0011

Ti 0.0003 0.0011 0.0009

Cu 0.0001 0.0100 0.0015

Mo 0.0007 0.0020 0.0004

V 0.0005 0.0020 0.0003

N 0.0015 0.0025 0.0038

H 0.0001 0.0001 0.0013

O 0.0010 0.0030 0.0574

Purity of Fe 99.9868 99.8876 99.9185

Inspection & Approval Certificates : C/W Certificate (Calibration Works Certificate) EN 10204 3.1 / DIN 50049 3.1 / ISO 10474 3.1 Mill Test Certificate, NACE MR-0103 / NACE MR-0175 / ISO 15156, CE Marked, European Pressure Equipment Directive PED-2014/68/EU, AD-2000-WO, ASME Boiler & Pressure Vessel Code Sec.II Part A Ed. 2015, API 6A (American Petroleum Institute), with 3.2 certificate duly Certified & Approved by LRS (Lloyd's Register), GL (Germanischer Lloyd), BV (Bureau Veritas), DNV (Det Norske Veritas), ABS (American Bureau of Shipping), DNV-GL, SGS, TUV, RINA, IRS, NORSOK Approved Standard M-630, M-650 Rev.3, ROHS Compliant

If you have any requirement of above items, please feel free to contact us

Regards,

CONTACT PERSON :

MUKESH SHAH

Director

Mobile No. 0091 - 9820292499

Email - marketing@rolexmetals.com

ROLEX METAL DISTRIBUTORS

( A METAL & STEEL Company )

57-A, KHATARGALLI,

THAKURDWAR,

MUMBAI - 400002, INDIA.

TEL.No. 0091-22-23858802

TEL.No. 0091-22-23823963

FAX No. 0091-22-23898724

Email - marketing@rolexmetals.com

Website – www.rolexmetals.com

CHAIRMAN – chairman@rolexmetals.com

MANAGING DIRECTOR – managingdirector@rolexmetals.com

TECHNICAL DIRECTOR – technicaldirector@rolexmetals.com

SALES DIRECTOR – salesdirector@rolexmetals.com

COMMERCIAL DIRECTOR – commercialdirector@rolexmetals.com

COMMERCIAL MANAGER – commercial@rolexmetals.com

GENERAL MANAGER – generalmanager@rolexmetals.com

SALES MANAGER – salesmanager@rolexmetals.com

PURCHASE MANAGER – purchasemanager@rolexmetals.com

TECHNICAL MANAGER – technical@rolexmetals.com

WORKS MANAGER – worksmanager@rolexmetals.com

STORES MANAGER – stores@rolexmetals.com

WAREHOUSE MANAGER – warehouse@rolexmetals.com

SALES DOMESTIC – salesdomestic@rolexmetals.com

SALES INTERNATIONAL – salesinternational@rolexmetals.com

SALES GENERAL – sales@rolexmetals.com

PURCHASE GENERAL – purchase@rolexmetals.com

FINANCE MANAGER – finance@rolexmetals.com

ACCOUNTS MANAGER – accounts@rolexmetals.com

GENERAL INFORMATION – info@rolexmetals.com

EXPORT MANAGER – export@rolexmetals.com

IMPORT MANAGER – import@rolexmetals.com

AIR EXPORT – airexport@rolexmetals.com

SEA EXPORT – seaexport@rolexmetals.com

CUSTOMS – customs@rolexmetals.com

AIR FREIGHT – airfreight@rolexmetals.com

SEA FREIGHT – seafreight@rolexmetals.com

DESPATCH – despatch@rolexmetals.com

INSPECTION – inspection@rolexmetals.com

LOGISTICS – logistics@rolexmetals.com

TRANSPORT – transport@rolexmetals.com

KALAMBOLI WAREHOUSE – kalamboli@rolexmetals.com

TALOJA WAREHOUSE – taloja@rolexmetals.com

KHOPOLI WAREHOUSE – khopoli@rolexmetals.com

NHAVA SHEVA WAREHOUSE – nhavasheva@rolexmetals.com

KANDLA WAREHOUSE – kandla@rolexmetals.com

MUMBAI WAREHOUSE – mumbai@rolexmetals.com

STOCKYARD – stockyard@rolexmetals.com

SERVICE – service@rolexmetals.com

SUPPORT – support@rolexmetals.com

RECRUITMENT – career@rolexmetals.com

WEBMASTER – webmaster@rolexmetals.com

CUSTOMER CARE – customercare@rolexmetals.com

Member Information

| ROLEX MATERIALS CORPORATION | |

|---|---|

| Country/Region: | India |

| Business Nature: | Trading Company |

| Phone: | 0091-9820292499 |

| Contact: | MUKESH SHAH (DIRECTOR) |

| Last Online: | 25 Oct, 2023 |