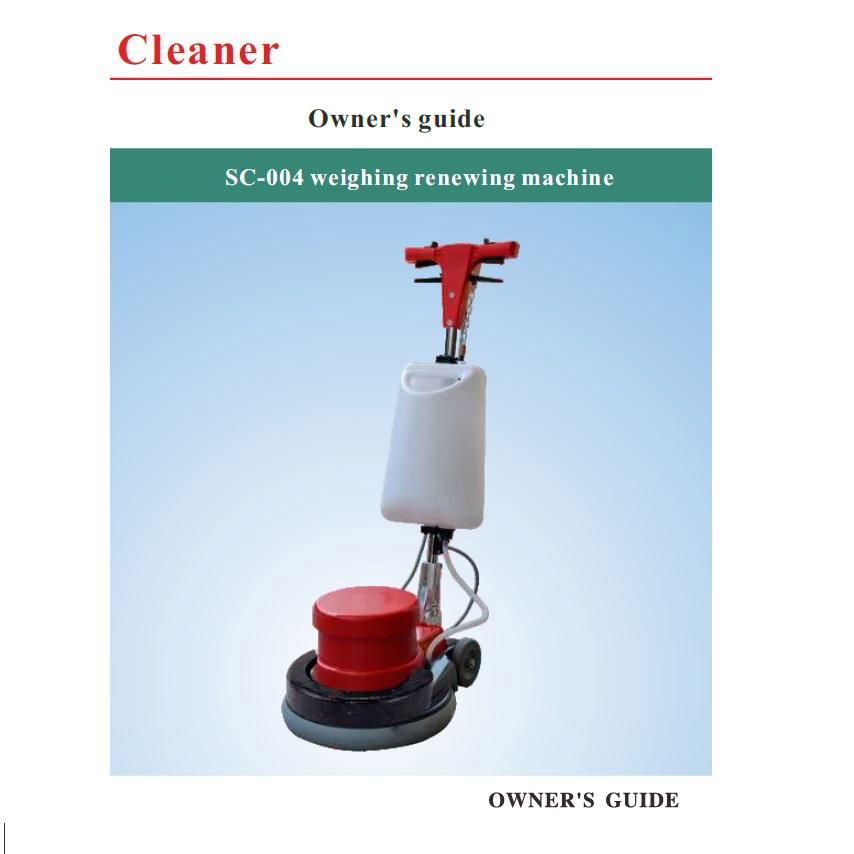

Floor Renewing Machine SC-004

Features:

The AC monopole asynchronous motor is made from import cold rolled silicon-steel

sheets of high quality, so it has high power, low loss and heat.

The reducer with

planetary gears is made from cast irons of high quality so as to reduce noise and the

gears which are helical are made from POM with high quality.

The motor cover and

machine body is made from aluminum alloy of high quality so as to ensure sufficient

structure strength and beautiful appearance.

Technical Data:

| Item |

SC-004 |

| Voltage/Frequency: |

220V-240V/50Hz |

| Power: |

1500W |

| Brush rotation speed; |

154rpm/min |

| Noise: |

≤54dB |

| Base plate diameter: |

17" |

| Main cable length: |

12m |

| Weight of the main body: |

34.2kg |

| Gross weight: |

73.66kg |

| Weighting iron weight: |

1X14.5kg |

| Handle packing size: |

375X126X1133mm |

| Main body packing size: |

560X450X350mm |

| Accessories: |

Main body, handle, water tank, pad holder, hard brush, soft brush, weighting irons, driving disk |

How to operation a floor renewing machine?

The handles are equipped with a mains switch and a protective device for the switch.

Adjust angles of the weighing renewing machine when it is unused. The angle adjusting handle can be raised, which is convenient for placing and saving space. Meanwhile, fixed sharp teeth of the operating handle are loosened. It is allowable to rotate the operating handle along the aluminum seat to a position vertical to the ground. Then loose the angle adjusting handle and the operating handle can be fixed to the vertical position. At the moment, safety device in the handle will clip in the safety groove of the main switch automatically. Even the fused switch is pushed to the center; it is still not powered on. Thus, it can prevent mal-operation and it can insure the operator's safety.

In normal usage, the angle adjusting handle should be raised up and it should be rotated to an angle accustomed by the operator (almost a 45°angle with the Ground). Then loose the angle adjusting handle and the operating angle is fixed.

When start cleaning, one of the two thumb fused switches are pushed to the center the

same moment at which the power switch is pressed down, so the motor is started to drive

the cleaning brush for working.

FAQ

Could we got samples before order?

Sure, we glad to got a sample or small trial order at first, from the samples you can know the quality and packing, test the function.

Do you have a minimum order quantity?

Yes, we require a MOQ for customized. Customer Logo and packing: floor machine series are about 10units, plastic cleaning tools more than 20units, chemical items about 300kg.

What is the average lead time?

For samples, the lead time is 1-3 days. For mass production, the lead time is 7-15 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal for SAMPLES.

For the mass, 30% deposit in advance, 70% balance against the copy of B/L, or against the Loading container.

What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone's satisfaction

How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

How to contact us?

Any questions please call or email Nicole as;