| Model: | SF250B |

|---|---|

| Brand: | KC |

| Origin: | Made In China |

| Category: | Industrial Supplies / Plate Making & Printing Machine |

| Label: | Flame treater , Flame machine , Treatment machine |

| Price: |

US $2838

/ pic

|

| Min. Order: | 1 pic |

Product Description

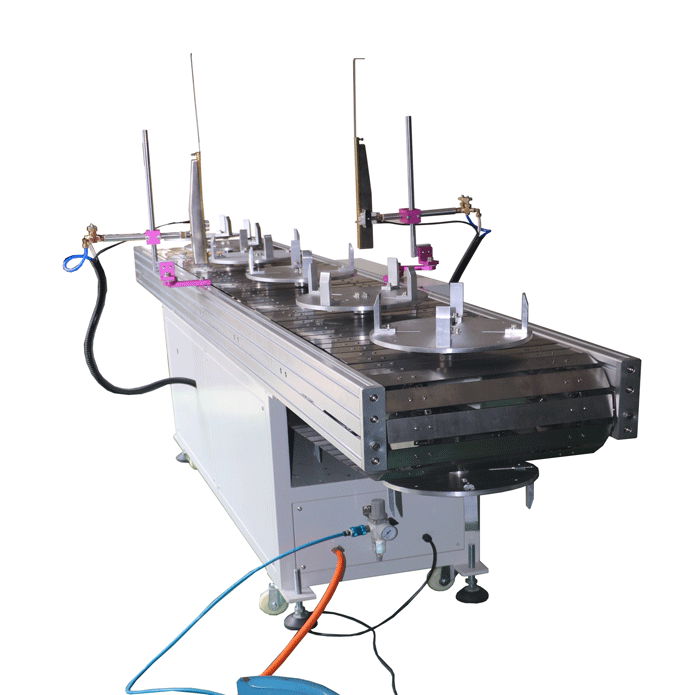

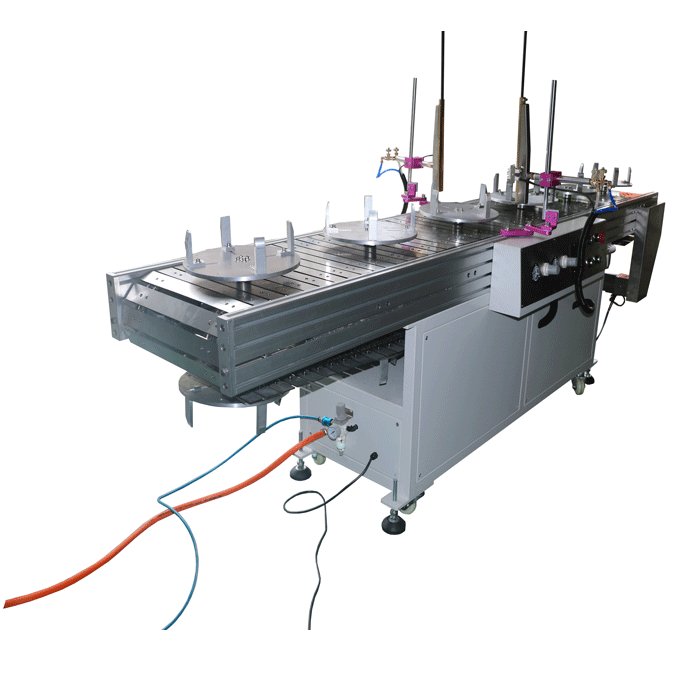

The printing of polyolefin materials often encounters the problem of ink shedding. The main reason is that it is composed of non-polar molecules. The printer will first choose a special polyolefin ink. If the adhesion of the ink does not meet the requirements, then Consider pre-treating the product surface, and flame treatment is a common and effective method.

The most suitable products for flame treatment are some cylindrical plastic bottles, and the effect is satisfactory no matter whether solvent-based ink or UV ink is used. The flame treatment machine for plastic bottles is composed of a flame generating device and a conveyor belt. The conveyor belt is often equipped with a rotatable support cone. The bottle can be inserted into the cone and enter the flame treatment head with the conveyor belt. The inside of the flame treatment head is filled with compressed air and Combustible gas, after ignition, sprays out a flame with pressure, which can oxidize the surface of the bottle. For automatic screen printing machines, flame treatment devices have almost become a standard configuration.

|

SF250B Cylinder bucket Flame treatment Machine /Structure |

|

|

Conveyor |

Stainless steel , Width: 400mm. |

|

Speed adjustment |

Stepless adjustment |

|

Ignition method |

Automatically |

|

Treat device |

Bucket rotating, Double flame mouth. |

|

Max Objects height |

400mm |

|

Transport adjustment |

Screw |

|

SF250B Cylinder bucket Flame treatment Machine//Usage and characters |

|

|

Guide |

|

|

Application fields |

|

|

SF250B Cylinder flame treatment Machine//Parameter |

|

|

Technical parameters |

|

|

Works supply |

|

|

Package list |

|

|

H.S.Code |

8443198000 |

|

Certificate |

CE |

|

SF250B Cylinder bucket Flame treatment Machine//Advantage |

|

|

Function |

|

| Application: | Before printing, PP and PE materials usually use pre-press treatment to improve the adhesion of the ink. There are many kinds of pre-press treatments, such as flame treatment, high-frequency treatment, plasma treatment, and chemical oxidation treatment. The flame treatment is the most widely used. It uses the jet flame to perform instantaneous high temperature oxidation treatment on the surface of the material, introduce polar molecules, and promote the combination with ink molecules. For plastic barrels with a relatively large diameter, the flame treatment machine needs a larger supporting chassis and a wider transmission width. A separate flame treatment machine is used in combination with a semi-automatic screen printing machine, while a fully automatic screen printing machine is specially installed with a flame treatment unit at the position before printing to realize the integration of flame treatment and screen printing. |

|---|---|

Member Information

| Dongguan KC Printing Machine Limited | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13592766499 |

| Contact: | Kelven Bai (General manager) |

| Last Online: | 08 Nov, 2024 |

Related Products of this Company

-

Webbing transfer machine(AA4290)

US $7666

-

Laser phototype-setting machine660FL

US $8875

-

High precision Electric circuit screen

US $7250

-

Cap hot stamping machine(H-TC50K)

US $1735

-

One color cylinder pad printer

US $2086

-

Drying closet (SM-120150DC)

US $1250

-

Hot stamping machine for Plastic crates

US $9565

-

plc Shuttle-Sealed cup pad printer

US $3996

-

Automatically ribbon Three colors screen

US $35626

-

Bottle cap side hot stamping machine

US $22047