| Model: | - |

|---|---|

| Brand: | - |

| Origin: | - |

| Category: | Security & Protection / Safety Products |

| Label: | Turbine Flow Meter , Vortex Flow Meter |

| Price: |

¥100

/ pc

|

| Min. Order: | 5 pc |

Product Description

Feejoy is very professional industrial instrumentation manufacturer for more than 16 years.Nowadays, it is not an era of lack of suppliers, what is worrying is how to find suitable and reliable ones among various suppliers. Our position is not to win on price, but to win with good quality and reasonable price, to win in the processing technology.we will offer level gauges,,industrial control and instrumentation,various liquid level sensors types,level gauge indicator,liquid level indicator sensor,level Transmitter,temperature transmitter,rotary paddle Level Switch,vibration Fork Level Switch,submersible Pressure Transmitter and so on.

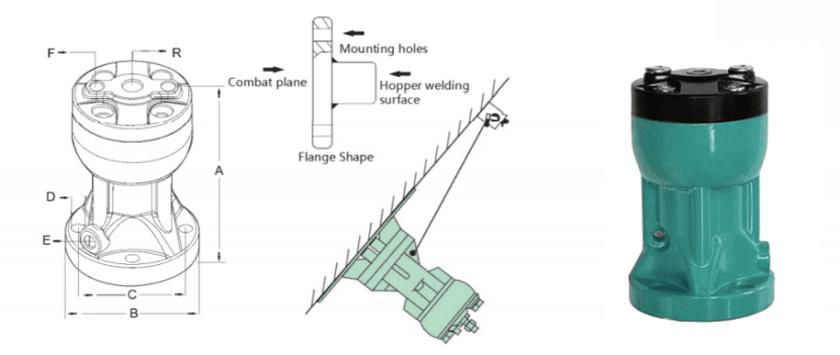

Best Quality Pneumatic Product Manufacturer

FEEJOY pneumatic products hammer is an advanced powder falling device commonly used at home and abroad. Vibronic point level detection offers safe overfill prevention in liquids and bulk solids in every industry, and it will not cause operation and deformation on the wall of the equipment, glass, cement, pharmaceutical, plastic, fuel and other powder processing industries.

We have a professional team to provide assistance in mechanical engineering, electrical engineering, product design and analysis. The pneumatic vibrators convert the pneumatic energy from compressed air into mechanical energy, causing a linear or circular movement. Find the right solution for your task at feejoygroup.com.

Introduction to Pneumatic Percussion Hammer

In a state where compressed air (more than 3Kg / cm) is not introduced into the pneumatic hammer, the magnetic piston is tightly fixed to the base plate with strong magnetic force. When the three-way solenoid valve is energized, compressed air flows into the pneumatic hammer body, and the pressure in the body increases. When the magnetic force is greater than the magnetic force, the magnetic piston detaches from the base plate at high speed, resulting in a strong counterforce due to the reaction force of strong magnetic force. The magnetic piston falling at high speed hits the substrate, and its impact force is transmitted to the silo, and the attached dust is knocked down with a strong impact force. When the three-way solenoid valve stops energizing, the compressed air in the pneumatic hammer body is discharged through the three-way solenoid valve, so the magnetic piston is slowly raised by the return spring and then close to the substrate, which is restored to the original state by the magnetic force.

There is a strong magnetic magnet inside the hammer head. Before the action, the magnetic hammer head is closely attached to the magnetic substrate. When the three-way solenoid valve is energized and the intake pressure is greater than the applied magnetic force, the magnetic hammer head is separated from the substrate at high speed and impacts the bottom After the impact, the three-way solenoid valve is powered off, the gas in the pneumatic product is eliminated, and the hammer head is reset. The impact force of the pneumatic percussion hammer is transmitted to the wall of the pipe or the barrel so that the material can flow smoothly. Widely used in powder processing industries such as chemical, fertilizer, pesticide, cement, fuel, etc.

Manufacturing Materials for Pneumatic Vibrators

There are many manufacturing materials for pneumatic vibrators, including carbon steel, cast iron, aluminum alloy, bronze, stainless steel and extruded aluminum. For applications in special environments, such as the pharmaceutical industry, the housing can be made of aluminum or stainless steel. Its vibration frequency and vibration strength can be accurately controlled by adjusting the flow and compressed air pressure (stepless adjustment). Its main advantages and uses include:

1. Only compressed air is needed as a power source, and the gas consumption is small, which is safe and energy-saving. It is an ideal device for use in freezing or high temperature environments, and is suitable for wet, dry, dusty, or explosive environments.

2. Small size, few failures, easy installation and maintenance.

3. Stop or start quickly, suitable for manual or automatic system.

4. Vibration force, vibration frequency and amplitude can be adjusted at will during the movement.

5. A wide range of applications, suitable for fatigue testing of parts or structural parts; jitter and compaction of hoppers; linear and bowl feeders, sieves and strainers; shakers and mixing equipment

6. The service life of most types of pneumatic vibrators is relatively low.

| Payment Terms: | T/T, L/C, VISA, Paypal, West Union |

|---|---|

Member Information

| Feejoy Technology (ShangHai) Co.,Ltd. | |

|---|---|

| Country/Region: | Shang Hai - China |

| Business Nature: | Manufacturer |

| Phone: | 15618968925 |

| Contact: | Ellen Wong (Foreign trade manage) |

| Last Online: | 04 Sep, 2020 |