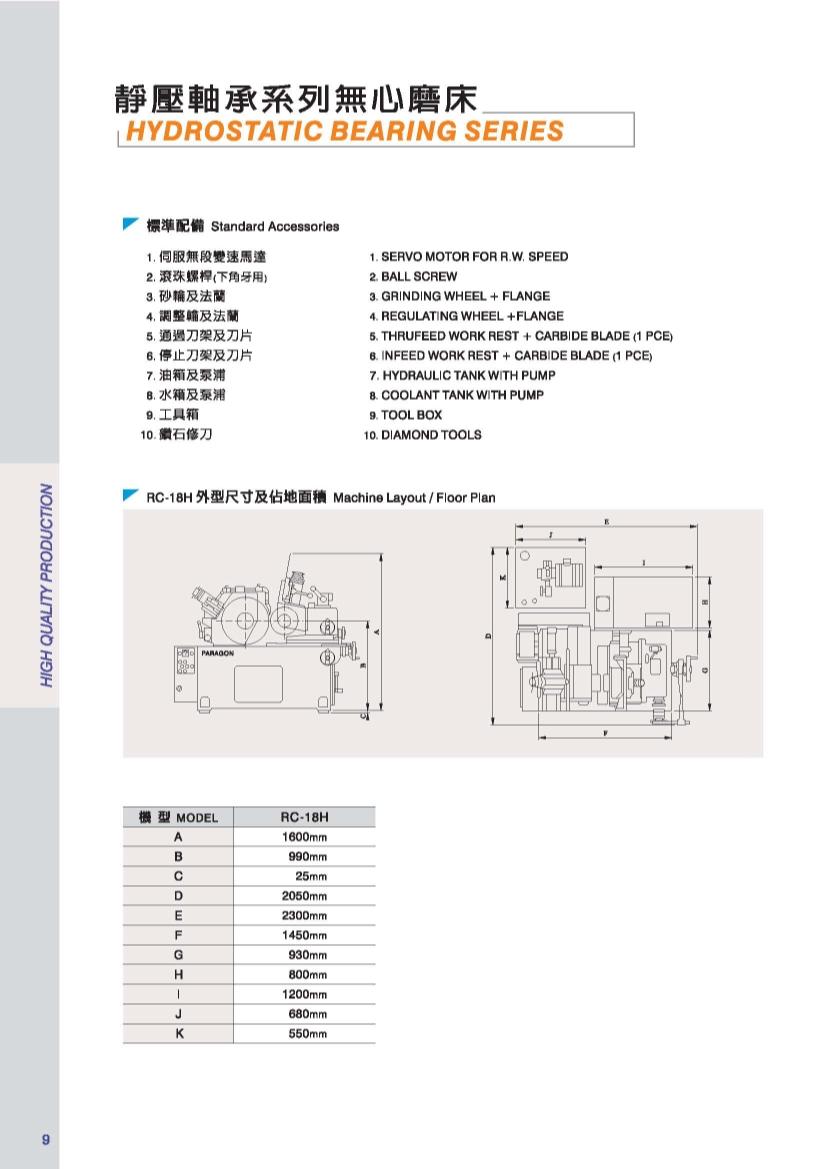

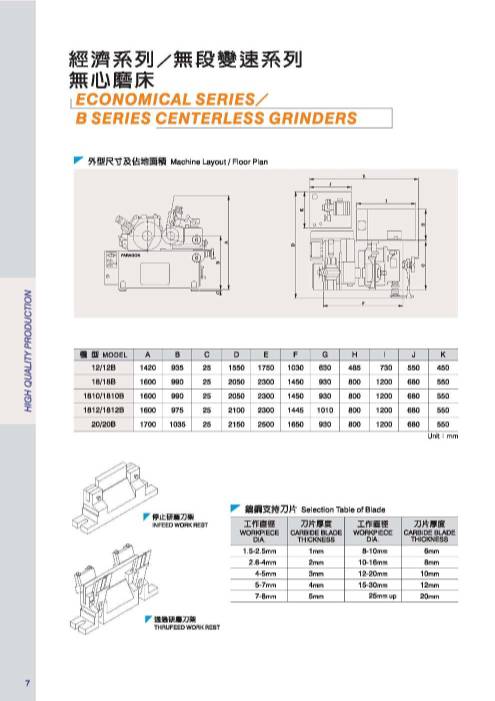

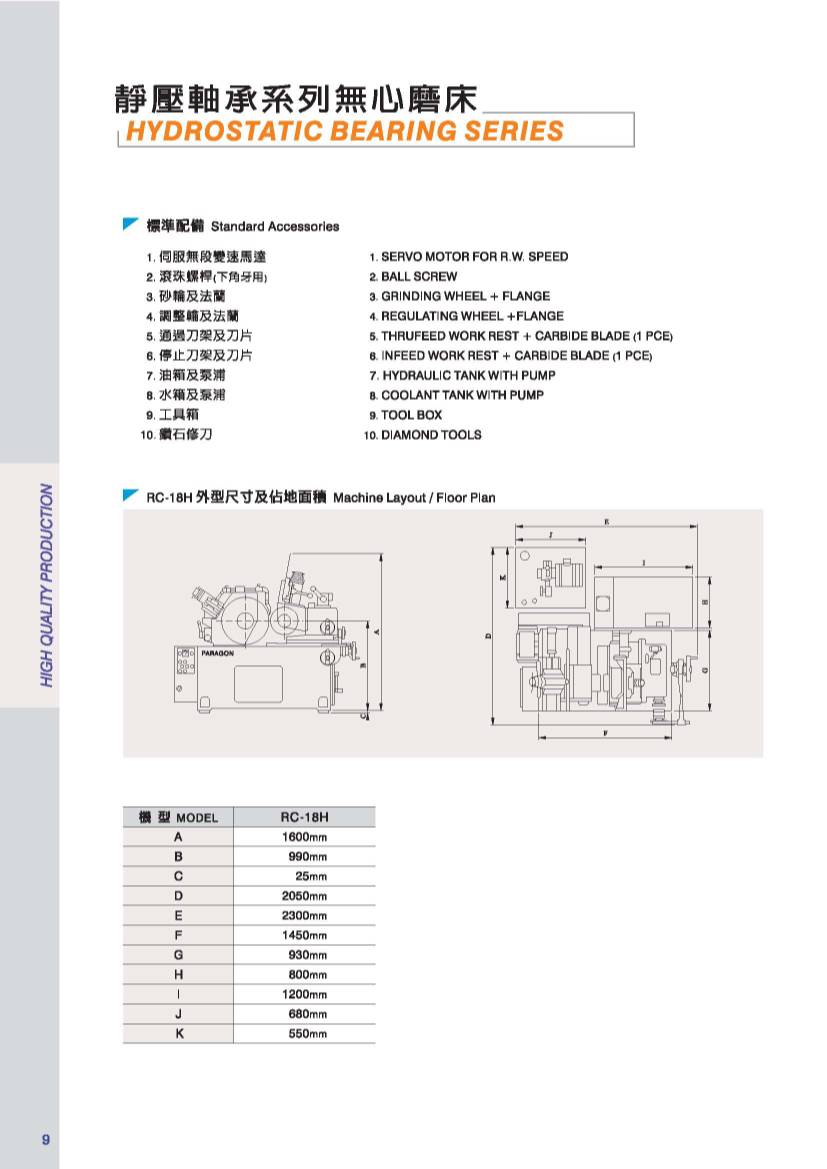

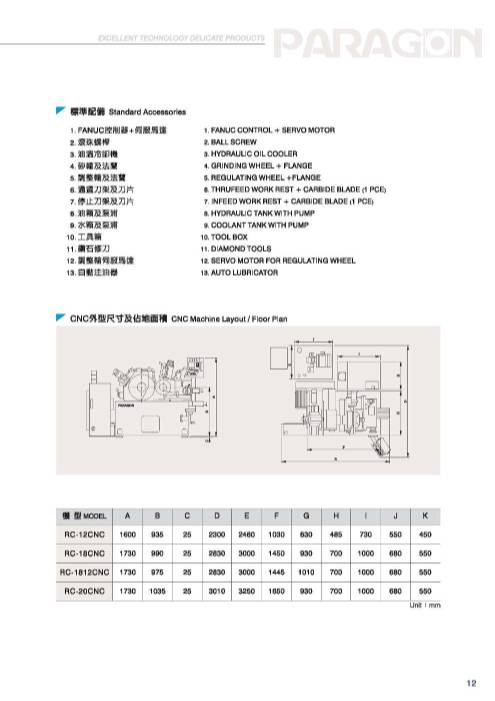

| Model: | RC-12B-16B |

|---|---|

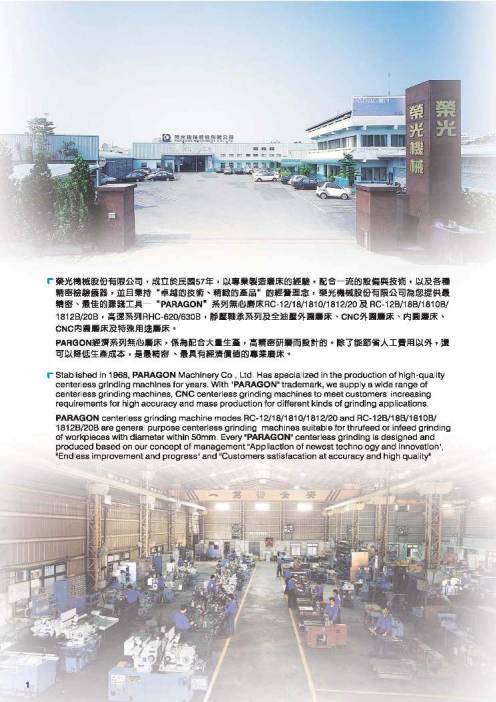

| Brand: | PARAGON MACHINERY |

| Origin: | Made In Taiwan, China |

| Category: | Industrial Supplies / Machinery / Machine Tool |

| Label: | PARAGON MACHINERY , Centerless Grinder , Internal Grinding Ma |

| Price: |

-

|

| Min. Order: | - |

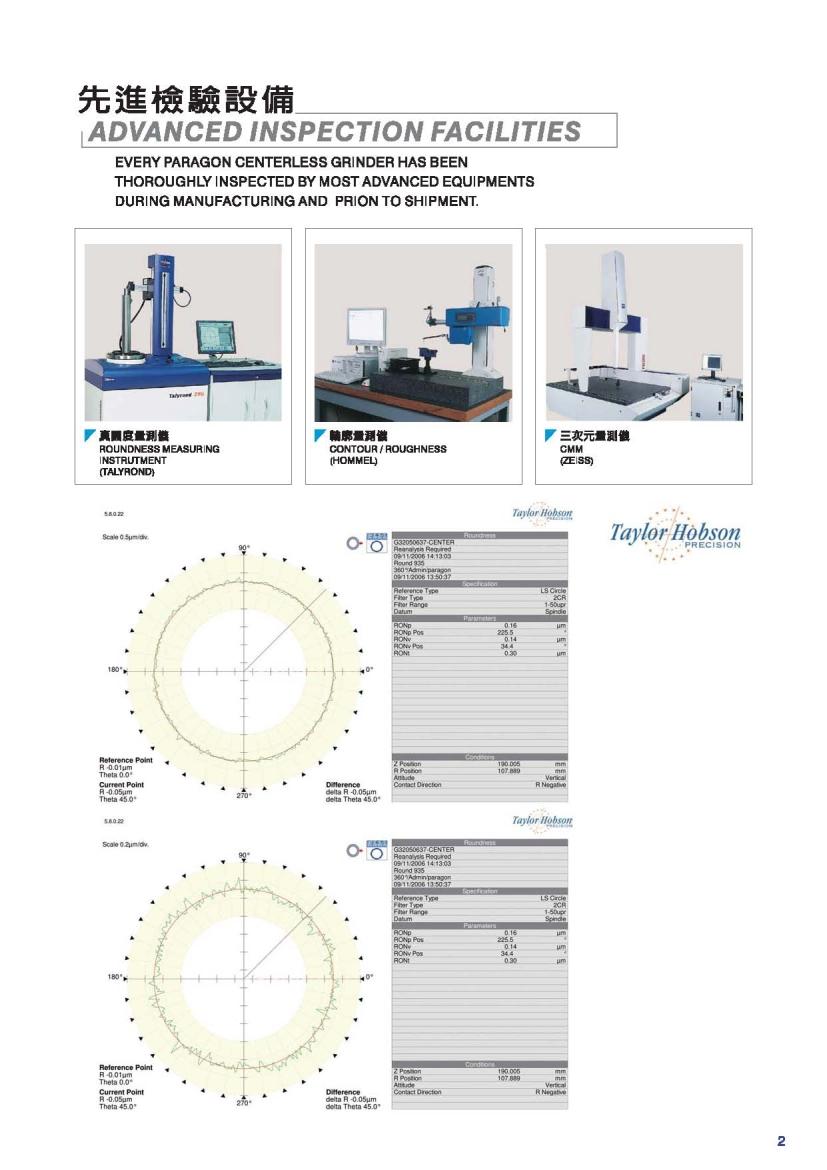

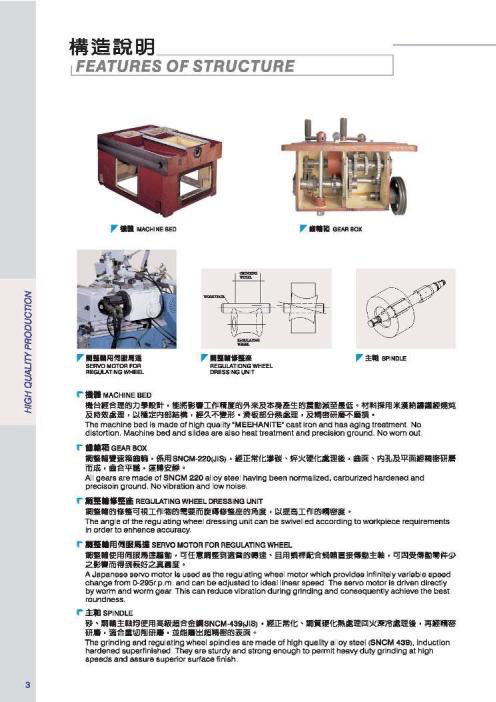

Product Description

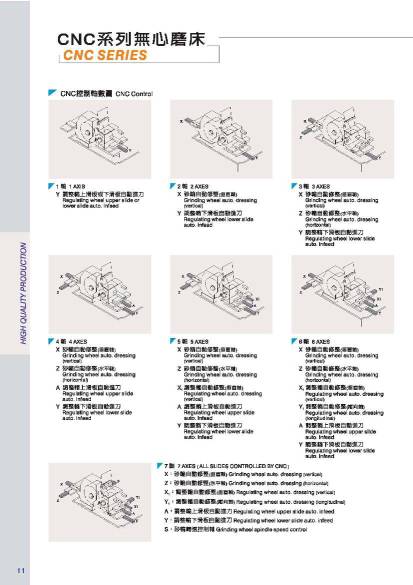

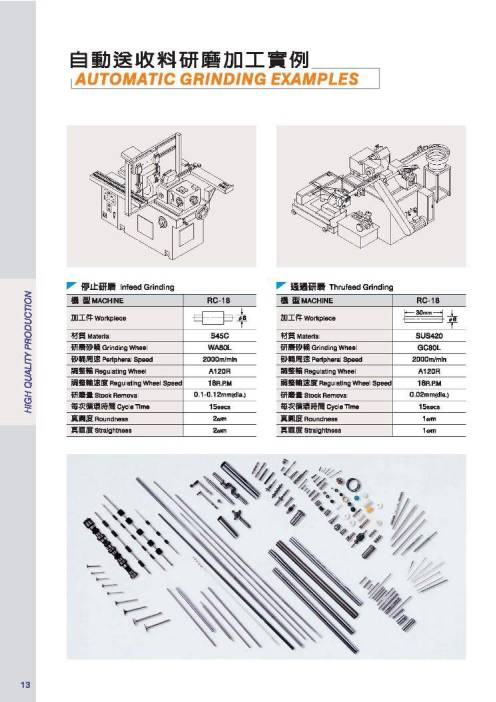

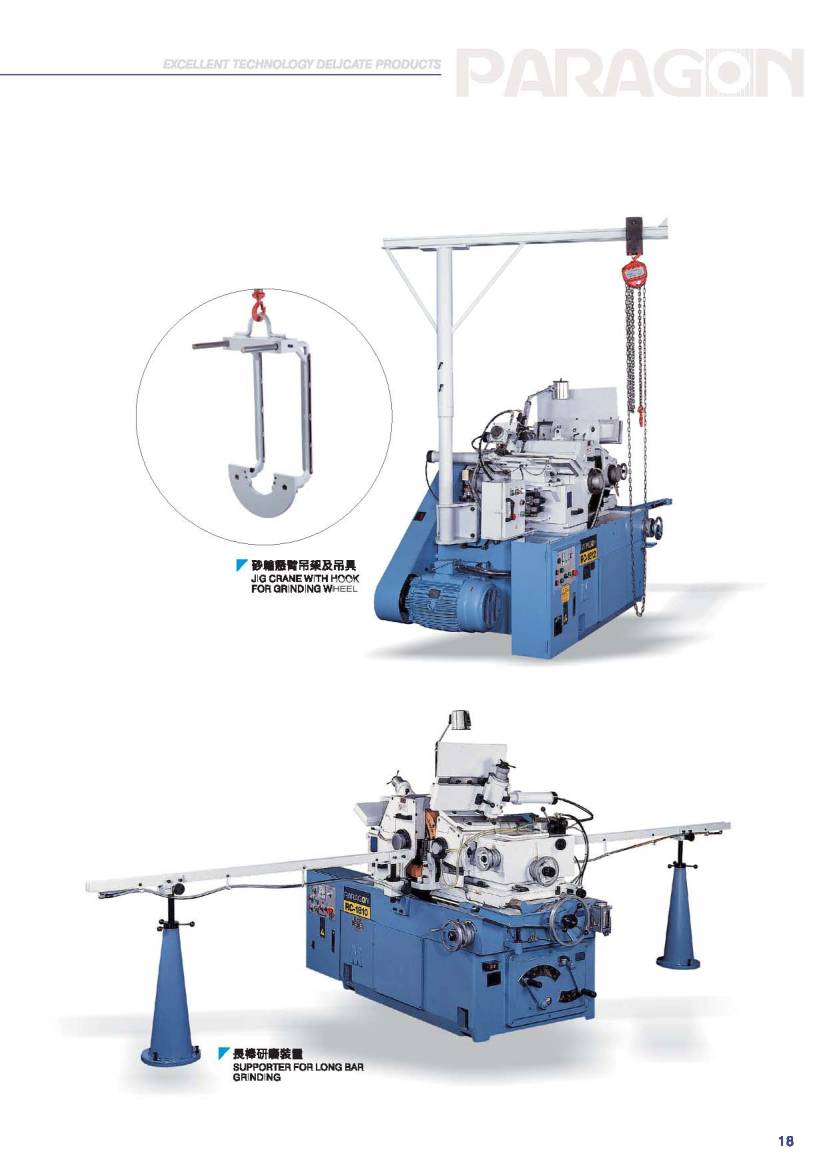

- Centerless Grinding Machines

- The RC series centerless grinding machines can be used for infeed grinding and thrufeed grinding to ensure accuracy, high productivity in workpieces with diameters between 1 mm and 50 mm. Automatic loading and unloading attachment is easy to operate, as well as reduce cost.