| Model: | B4C |

|---|---|

| Brand: | Calculus |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Spraying Machine & Spreading Equipment |

| Label: | boron carbide nozzle , b4c nozzle , sandblasting nozzle |

| Price: |

US $10

/ pc

|

| Min. Order: | 1 pc |

Product Description

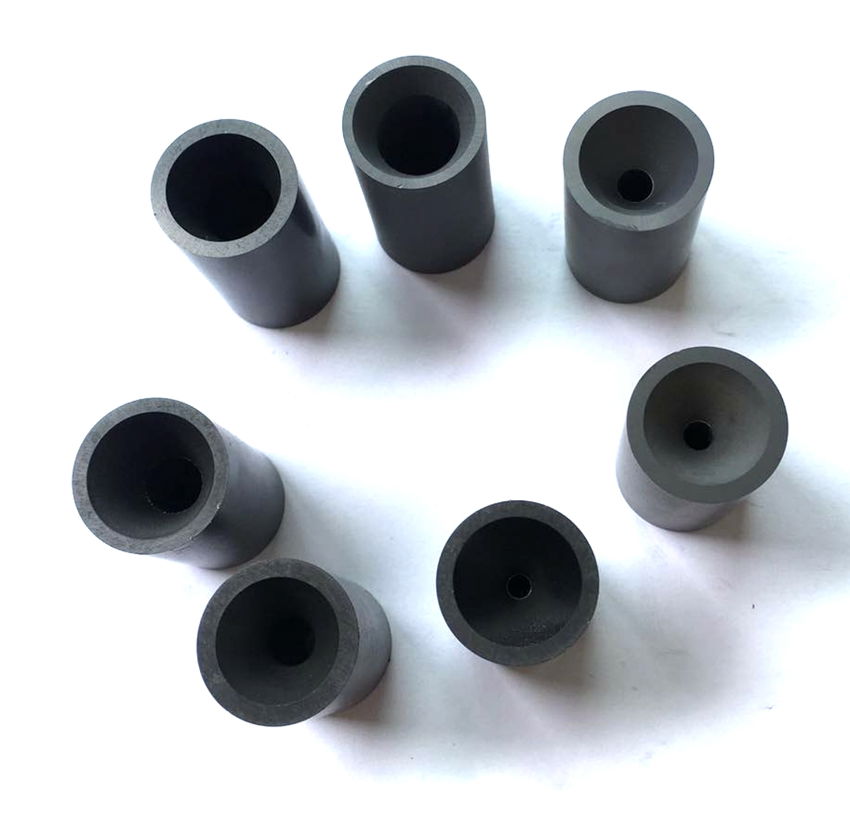

B4C boron carbide nozzles for sandblasting

Description:

Boron carbide (B4C) is one of the world's hardest manufactured materials. Its strong chemical bonds and hard surface minimize wear in rigorous environments. Boron carbides are often used in ballistic armor, taking advantage of exceptional hardness and low density. The hardness provides excellent protection, while the light-weight maximizes mobility. Additionally, the uniquely structured boron carbide can be used for neutron shielding.

The boron carbide material are in very high hardness, excellent wear resistance and the boron carbide won’t react with acid-base.

High/low temperature resistance, high pressure resistant, density≥2.46g/cm³,micro hardness≥3500kgf/mm², TRS≥400Mpa, melting point is

2450℃.

With above performance, the boron carbide are widely to make the sandblasting nozzles.

The boron carbide replace tungsten carbide, silicon carbide, silicon nitride, aluminium oxide,

zirconium oxide, etc.

The density also can be made to ≥2.48g/cm³. Higher density, better wear

resistance and longer using life.

Features:

1. High hardness

2. Excellent wear resistance

3. Good corrosion resistance

4. High temperature resistance

5. Density: ≥2.46g/cm3, ≥2.48g/cm3 or customized

6. Longer using life

• Low thermal conductivity

• Susceptible to thermal shock failure

• Outstanding hardness

• Extremely brittle

• Semiconductor

• Good thermal-neutron capture

With above features and advantage, many customers prefer the boron carbide nozzles to

replace the nozzles made from tungsten carbide, silicon carbide, silicon nitride, aluminium oxide, zirconium oxide, etc.

Nozzles types:

1. Straight Hole Nozzles

2. Long Venturi Nozzles

3. Double Venturi Nozzles

4. Angular Nozzles

5. Banana Nozzles

6. Wet Spray Nozzles

7. Internal Pipe Blasting Nozzles

8. Customized Nozzles

Approximate Nozzle Service Life in Hours :

|

Nozzle material |

Steel Shot and Grit |

Expendable Abrasives |

Aluoxide Abrasives |

|

Alumina |

20-40 |

10-30 |

1-4 |

|

Tungsten Carbide |

500 - 800 |

300 - 400 |

20-40 |

|

Silicon carbide |

600-1000 |

400-600 |

50-100 |

|

Boron Carbide |

1500 - 2500 |

750 - 1500 |

200 -1000 |

Size refer:

|

Part Number |

ID(mm) |

OD(mm) |

Length(mm) |

|

BC35 |

4,6,8,10 |

20 |

35 |

|

BC45 |

4,6,8,10 |

20 |

45 |

|

BC55 |

4,6,8,10 |

20 |

55 |

|

BC60 |

4,6,8,10 |

20 |

60 |

|

BC80 |

4,6,8,10 |

20 |

80

|

Please contact us if you need more details~

| Payment Terms: | TT,Western Union,Paypal |

|---|---|

Member Information

| Changsha Harder Material Technology Co., Ltd. | |

|---|---|

| Country/Region: | Hu Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 13026659736 |

| Contact: | Me lody (Sales manager) |

| Last Online: | 20 Mar, 2023 |