| Model: | CLC-Q2 |

|---|---|

| Brand: | CLC |

| Origin: | Made In China |

| Category: | Industrial Supplies / Packaging Related Machine |

| Label: | - |

| Price: |

US $100000

/ pc

|

| Min. Order: | 1 pc |

Product Description

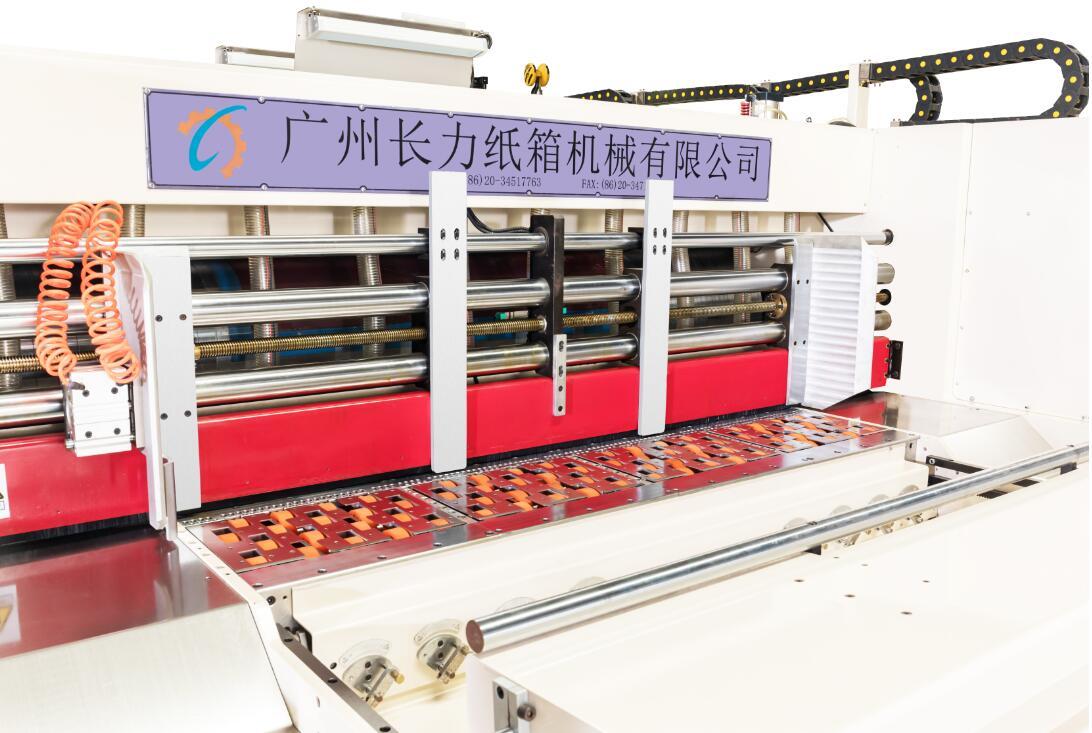

Three /Four Color Flexo Printer Slotter

- Basic information

Three Color Flexo Printer Slotter, model CLC-Q2-0920 Effective width 2000mm, Model 1224 effective width 2400mm, model 1628 effective width 2800mm. It specially be used to make the products with 1-3 color image.

The gap adjustment is controlled by manual with self-locking handle and sheet transferred by pull roller. It is economic one with high performance and cost saving.

|

|

Model MM |

CLC-Q2-0920 |

CLC-Q2-1224 |

||

|

|

Max. Sheet Size (FxA) |

890x2000 |

1190x2400 |

||

|

|

Skip Feed Size (FxA) |

1200x2000 |

1400x2400 |

||

|

|

Min. Sheet Size (FxA) |

280x700 |

350x720 |

||

|

|

Max. Printing Area (FxA) |

890x1960 |

1190x2360 |

||

|

|

Top Speed(Sheet/min) |

300 |

250 |

||

|

|

Economic Speed (sheet/min) |

150-250 |

120-220 |

||

|

|

Min. Slotting Space-Reverse Knife (BxCxBxC) |

270x100x270x100 |

270x100x270x100 |

||

|

|

Min. Slotting Space-Normal Knife (BxCxBxC) |

160x160x160x160 |

160x160x160x160 |

||

|

|

Max. Slot Depth Size |

250 |

320 |

||

|

|

Min. Box Height Size(E) |

110 |

110 |

||

|

|

Max. Die-Cutting Area (FxA) |

850x1950 |

1150x2350 |

||

|

|

Sheet Thickness |

1.5-11 |

1.5-11 |

||

|

|

Thickness of Printing Plate(Include R-Bak, Hang Film) |

7.2 |

7.2 |

||

|

|

Main Woring Power(KW) |

4 Colors Slotter Die-cutter |

47 |

54 |

|

|

|

Stacker + Vibrator |

3+10 |

3+10 |

||

|

|

Total Power(KW) |

4 Colors Slotter Die-cutter |

59.5 |

66.5 |

|

|

|

Stacker + Vibrator |

3+10 |

3+10 |

||

|

|

Dimension (mm) |

4 Colors Slotter Die-cutter |

6600x4950x2550 |

9900x5350x2650 |

|

|

|

Stacker |

6500x3500x3000 |

6500x3970x3000 |

||

|

|

Vibrator |

3200x3300x1100 |

3200x3700x1100 |

||

|

Feeding accuracy |

≤ ±1.5 mm |

||||

|

Printing (4 colors) accuracy |

≤ ± 0.5 mm |

||||

|

Slotting accuracy |

≤ ±1.5 mm |

||||

|

Die-cutting accuracy |

≤ ± 1.5 mm |

||||

- Product details

- Feeding Unit

- Mechanical Lead edge feeder.

- Can use Skip Feeding to extend the sheet high

- Strong dust blower with two sets of brushes is used to remove paper scraps and dust on the surface of cardboard.

- Little vibration and speed-up.

- Printing Unit

- Sheet transfer with Roll-To-Roll.

- Full layout hanging-plate slot, applicable to 3X10mm hanging-plate bar..

- Double Load type Planetary gear structure is adopted for printing register, the clearance can be fine-tuned to ensure more accurate transmission, 360ºprecisely adjusted.

- Combining both Independent PLC and LCD touch screen, the phase recovery can be achieved quickly, so that help to increase the ordering speed and reduce the waste of testing paper.

- Slotting Unit

- Sheet transfer with rollers.

- Central-knife is moveable.

- Slotting register digitally controlled by touch screen and PLC. It could be controlled by motor with display as well.

- The main control panel is set in this unit. The transversal, box height, and slotting register can be adjusted with order management system or can be motorized adjusted also.

- Die cutting Unit

- Sheet transfer with rollers.

- Die-cutting Anvil Cylinder is covered by rubber, (made from Italy), and Button-type structure is adopted for easy replace.

- Equipped with Anvil Rubber Grinding Device, Anvil Rubber can be turned many times for repeatedly used.

- Die-cutting register is digitally motorized, auto zero and auto reset.

- Auto Stacker

- Gantry type hydraulic lifting structure.

- Arm height is pneumatically controlled by the hand valve.

Box making machine

Corrugated carton box making machineis designed to process corrugated cardboard into products such as cartons, boxes, trays, displays etc.

It can finish the process of feeding, printing, pre-creasing, creasing, slotting, die-cutting, gluing, stitching and stacking at one time.

Corrugated paper is fed to the feeding unit. After printed by the printing unit, paper will go to the slotting unit, creased and cut by it, or transferred to die cutting unit. Then carry out into gluing or stitching machine, jointed by it. Then, papers comes out for packing even directly for use.

Member Information

| Foshan CLC Precision Machinery Technology Co.,Ltd. | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13928823499 |

| Contact: | ming he (Sales Manager) |

| Last Online: | 04 Oct, 2021 |

Related Products of this Company

-

Auto Folder Gluer Machine

US $50000

-

Semi auto Stitching Machine

US $18000

-

Corrugated Carton Box Making Machine

US $120000