| Model: | ERW 32-720 |

|---|---|

| Brand: | ZTZG |

| Origin: | - |

| Category: | Industrial Supplies / Machinery / Welding Machinery |

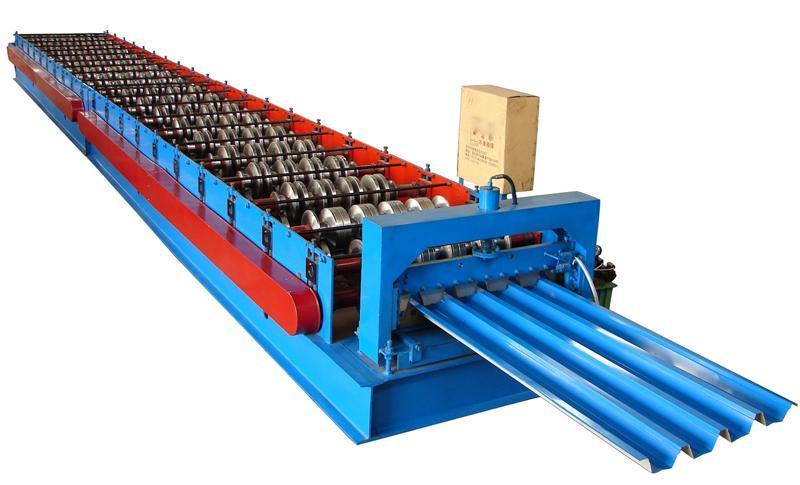

| Label: | Tile Machine , cold roll forming |

| Price: |

US $20000

/ Set

|

| Min. Order: | 1 Set |

Product Description

|

Product Parameter |

||

|

Raw Material |

Type |

PPGI, Carbon steel, HR, CR, MS |

|

Thickness |

1-3mm |

|

|

Products size |

As drawing |

|

|

Operation |

Manual |

|

|

Roll Forming Section |

Roller material |

45# steel with 0.05mm chrome |

|

Shaft material |

45# with 0.05mm chrome |

|

|

Diameter of shaft |

65 mm |

|

|

Power |

Main motor |

11KW*2 |

|

Pump motor for cutter |

18.5KW |

|

|

Coil ID |

580-700mm |

|

|

Voltage |

Customized |

|

|

Types |

PLC control system |

|

Company Profie

Why Choose Us

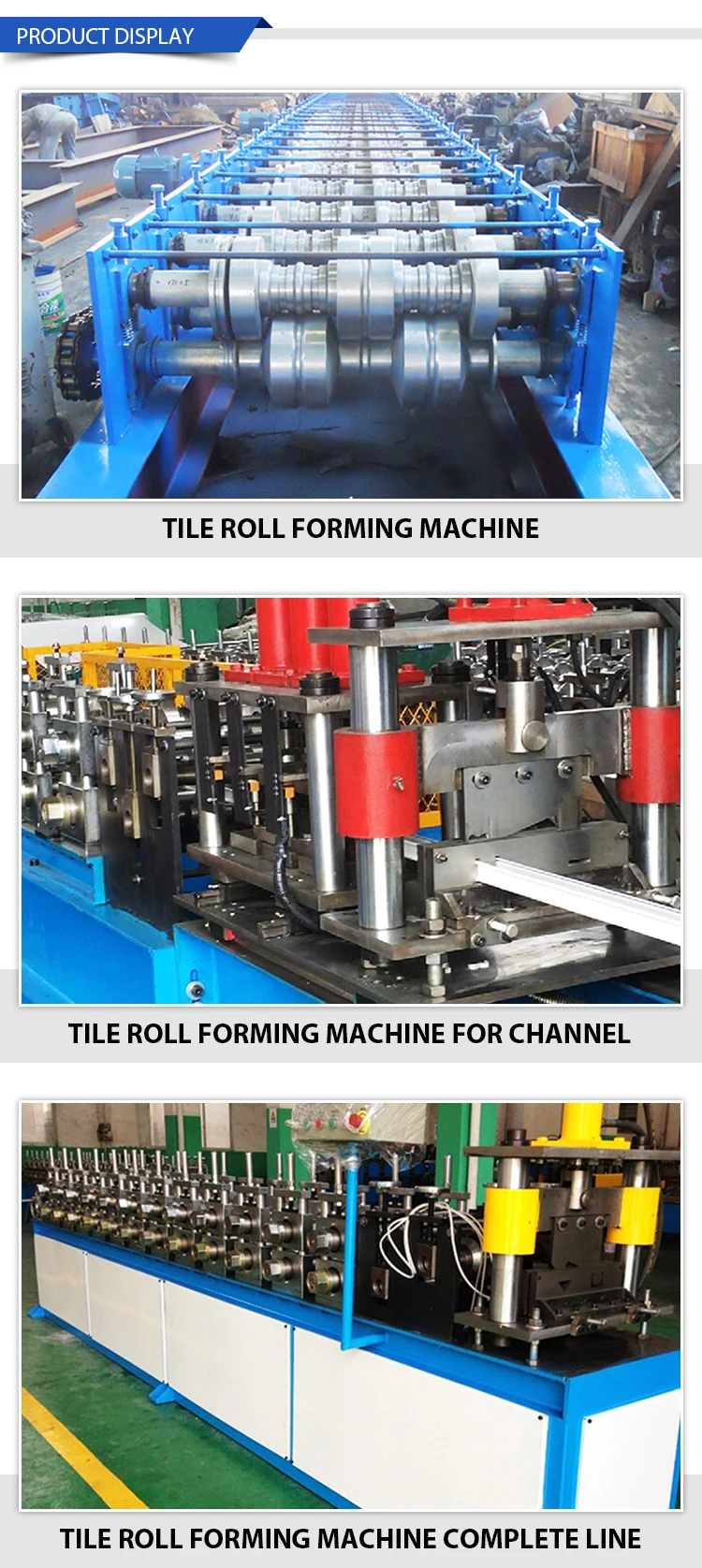

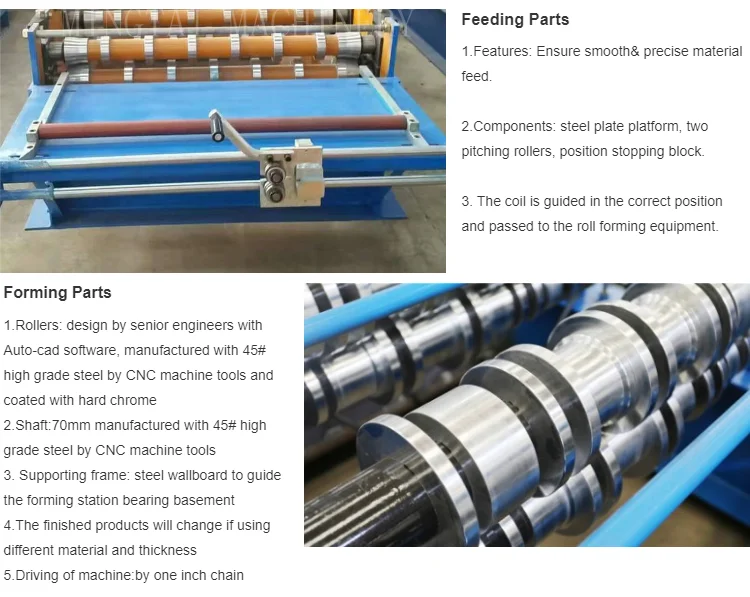

Universal Horizontal Roll Stand This stand consist of two horizontal roller shafts along with two side-vertical roller shafts, which helps adjust the tube forming and pipe orienting. Billet tube entering this section will be turned one step closer to the complete product with their gap gradually closed and all facing 12 o’clock direction waiting to be welded.

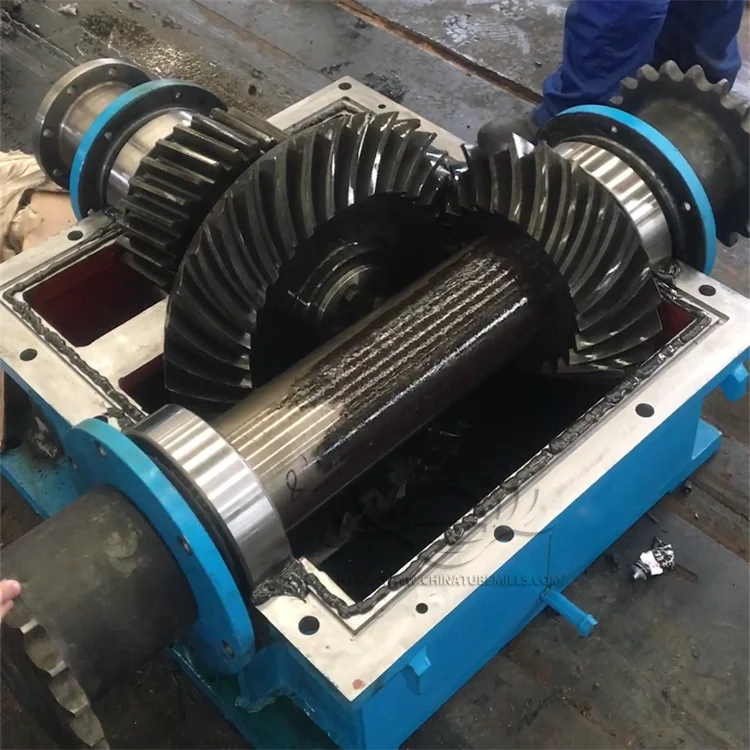

High modulus for gear boxes, makes stronger machine and higher rigidity, which is very important to realized the schemed speed for the pipe production line.

Copper is used as the material of the sliding block in the vertical roller stand. It will prevent rust because this part is easy to be splashed with water.

We buy genuine material form formal manufacturer of steel raw material, ensuring the quality of the machine.

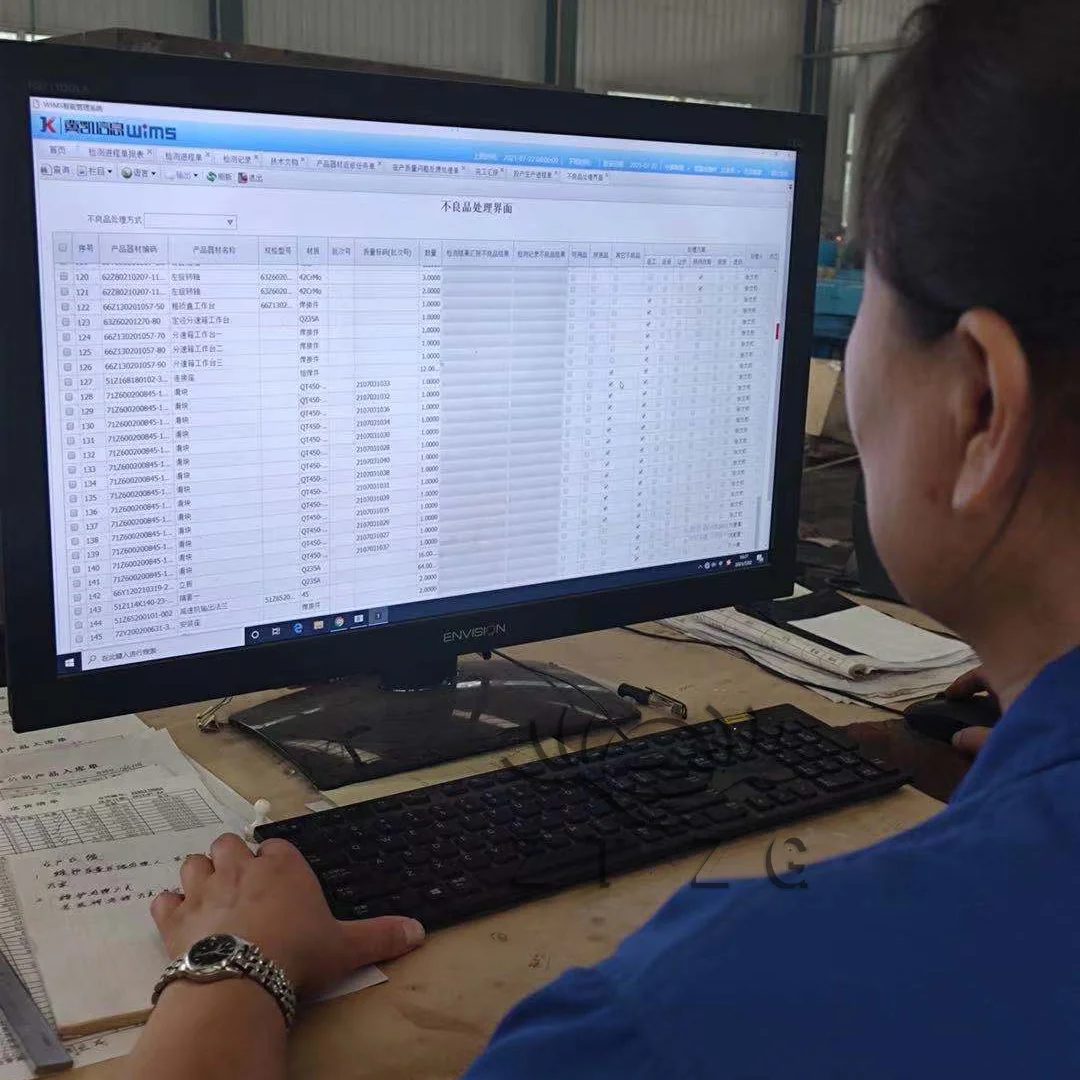

Wims Quality Control System

Each part, even a nut is traceable in this system. If there is any problem we can trace back to the person who is responsable.

Wims Quality Control System

Each part, even a nut is traceable in this system. If there is any problem we can trace back to the person who is responsable.

Wims Quality Control System

Each part, even a nut is traceable in this system. If there is any problem we can trace back to the person who is responsable.

We Import High Precision Machinery

CNC Flame Plasma Cutting Machine 2

CNC Plano Milling Machine 2

Cutting Machine(GZK4240, GW4038) 5

CNC Machining Center 1

CNC Lathe (HK63B, SK50P) 10

Milling Machine 3

Lathe 15

Wire Cutting Machine 3

CNC Boring Machine (TPX6111) 1

Radial Drilling Machine 2

Heat Treatment Equipment 15

Carburizing & Nitriding Furnace 1

Intermediate Frequency Furnace 2

Painting Equipment 1

We Import High Precision Machinery

CNC Flame Plasma Cutting Machine 2CNC Plano Milling Machine 2

Cutting Machine(GZK4240, GW4038) 5

CNC Machining Center 1

CNC Lathe (HK63B, SK50P) 10

Milling Machine 3

Lathe 15

Wire Cutting Machine 3

CNC Boring Machine (TPX6111) 1

Radial Drilling Machine 2

Heat Treatment Equipment 15

Carburizing & Nitriding Furnace 1

Intermediate Frequency Furnace 2

Painting Equipment 1

Workingshop Work Tusk is Easy

All computer controlled, workers only need to put things together under the system instructions.

Successful Cases

Exhibition

Product packaging

FAQ

Q: Are you a manufacturer?

A: Yes, we are a manufacturer. We have 4 factories ( Machining, Assembling, Heat treatment, and Moulding ). We also have our own R&D department. Welcome to visit us.

Q: What kind of payment term do you do?

A: We do T/T.

Q: What info do you need before giving me the price and proposal?

A: Since we design individual machines based on our customer's requirements, we need your desired products' basic dimensions, including all the pipe diameter(or tube length), thickness range, usage, raw material steel grade, coil weight, and degree of automation.

Q: What should I do if I just start a new business?

A: Contact us immediately, we provide a free consultant for pre-sales service. Also, we can help you solve the raw material (steel coil) purchase, worker training, international market price, and more.

Q: How do you do QA?

A: We have a special team to do strict QA, this is one of our strengths:

(1)Every gearbox will be tested for 8 hours with oil inside to guarantee there is no leak.

(2)Every shaft will be inspected for centering jumpiness.

(3)Every roller will be checked to make sure it's in the range of tolerance critical parts will be inspected for all dimensions.

Q: Why I should choose you? what are the differences between you and other Chinese suppliers?

A: We are concentrating on pipe-making machines for more than 20 years. We have constructed many steady trading partners in Asia, Africa, the middle east, Europe, and South America throughout the years. Our innovative designed production line and every single unit of the production line are economical and practical.

Member Information

| ZTZG Company | |

|---|---|

| Country/Region: | He Bei - China |

| Business Nature: | Manufacturer |

| Phone: | 18069083792 |

| Contact: | Sharon Lv (Sales Manager) |

| Last Online: | 11 Oct, 2021 |