| Model: | - |

|---|---|

| Brand: | Packson |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machine Hardware / Mold |

| Label: | soft tooling for inj |

| Price: |

US $100

/ pc

|

| Min. Order: | 1 pc |

Product Description

ISO Class 8 Clean Room

Quality Control

Low & High Volume Manufacturing

Competitive Price

Reliability and Stability

Prototype injection molds are rapid processing for the molds. It's totally different from production molds as they can't be used in the long term. As a professional mold maker for over 15 years, Packson can handle all kinds of mold including prototypes. We bring not only high skilled engineering team into the good design but also allow us to provide competitive prices and high-quality molds. Most of our prototypes mold customers are from Honda. Every design needs proofing before they are produced by mass molding production especially for the automotive parts.

We will also make personal solutions for prototype plastic injection molding just the same as production tooling. We share engineering information between our teams and our customers. Keeping close contact with our customers is one of the important factors that Packson has good performance in making soft tooling for injection molding. Therefore, we ensure that our communications between the engineering team and customers are always open and transparent.

Prototype Mold Details And Options

We believe that it's important to test your market by first testing your product. Packson offers you an affordable method of testing with prototype parts. Our prototype processing helps you test your part design and make a small batch of parts for assembly testing. You may not very clear about the definition of prototype molds and the differences between prototype molds and injection molds. Here we can explain it for you:

Process For Prototype Mold

There are many things that need to be considered such as the product design needs to be perfect and it has to achieve actual full functionality before they get into the market. If there is any failure for your products which means the part design is not fulfilled yet and we need to keep improving the design and finding a better solution. Therefore, prototype mold is the best way for us to prove some issues before you are able to take your products into the market. Here is the process for prototype mold, you will find out what prototype mold exactly is:

There are 4 simple steps for prototype mold:

- Start with a plastic part design

Initial concept or design is always the essential and critical part of manufacturing.No matter what kind of product you create like an electronic device or medical device, making the design and design should be the first step.

You should make sure of the feasibility and functionality when it comes to plastic product design. Moreover, you have to consider the concept is doable or not. If the design fails then it would waste time. But never mind, we have a professional engineer team who will make assessments for your design and provide our s estions to help make the design better.

- Providing DFM(Design for Manufacturing) and processing solution

We will make DFM according to your part design and offer a processing solution at a competitive price. Normally we will choose a removable insert which takes by hand during production, this will help cut injection molding prototype cost. But this is only used for small batch production within 500 shots. We will also analyze the thickness, angle draft, injection point, etc during these steps for making sure everything is ok before we start processing.

- Mold creation or 3D printing

Simple 3D printing is fully sufficient for simple and small quantity plastic products. Therefore the expensive test mold is not neccessary.3D printing is a very simple process without much explanation. For another processing, the way is mold creation. This is the most important process in plastic prototyping. We will process the mold according to the tooling design and we will choose the steel which is softer and easier to carve out. This will help to make mold quickly with a short lead time. Rapid processing is one of the obvious features of the prototype mold. Because we don't need to make it like production mold as long as it can be operated and good for proving the customer's part design.

- Making the prototype plastic molding parts by injection machine

For prototype mold, the plastic parts also need to be molded by a plastic injection machine. The mold will be placed into the rapid prototyping plastic injection molding machine and then injected with the plastic prototype material. Later material will be cooled by the water lines to allow it to create a shape on the cavity. After the cooling process, the mold will be opened when pressure from the clamp is released. Finally, the part will be ejected from the machine.

Applications of Prototype Mold

There are many applications for prototype molds like automotive, medical. These applications will keep increasing because of the development of new procedures. Here are some of them:

The prototype mold making – different grades of steel even plastic resin can be made through prototype mold.

The making of cores – SLS application is the latest technology used in sand casting shapes and cores.

The electrodes for EDM, making of marking stamps are some of the applications of prototype molds. Most of the applicated industry at Packson is automotive and medical.

There are many benefits for the prototype molds. With the features of low cost, quick lead time, and effective processing way, it will allow you to bring your parts into the market faster. The most important advantage is low-cost processing because it can make market testing with low volume production.

Why Choose Packson For Prototype Mold?

Prototype molds serve a different purpose. They are different from the production mold. First, they are pre-production molds which applied in testing and solving issues before a final product gets into molding processing. With a shorter lead time, prototype molds help create test products with further studies.

Here Packson offers you low-cost prototype molds by alternative means of:

- Producing a small batch of molding parts so you can test the physical properties of the production parts

- Proofing the concept design for the part and then make improvements for the part

- Narrowing down material choosing determine what materials work best

At Packson, your first small steps are a critical part of the larger leap forward. Get your part get into the market quickly with Packson by contacting us today!

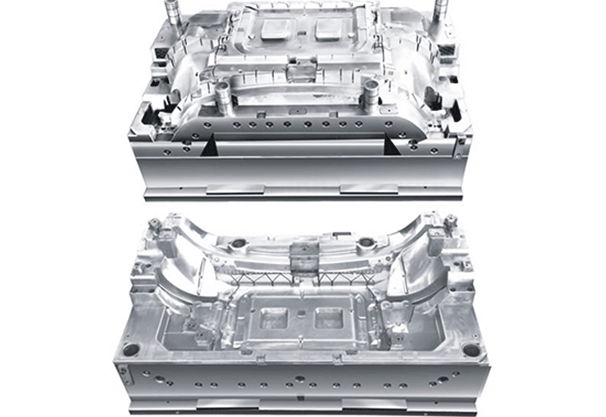

Packson Prototype Mold Show

Packson - Your Injection Moulding Manufacture

Your expert in quick turn injection molding

ISO Class 8 Clean Room

Equipped with clean room and certificated with ISO 13485 and ISO 9001, we are able to hanlde your medical OEMS production.

Quality Control

We will check color, appearnce and tolerance by qulity control at every step during manufacturing process.

Low & High Volume Manufacturing

Except long run production, we also can provide better solution for your low-volume production by prototyping tooling.

Competitive Price

Our good investments in euipments and QC system help us to get greater efficiency and higher quality which decrease reject ratio. All these make us send parts to you on time with competitive cost.

Reliability and Stability

Our 24 hours|3 shifts production system help your parts get into market quickly and steadily.

Related Injection Molding Services From Packson

| Payment Terms: | TT |

|---|---|

Member Information

| Packson Mold Co.,Ltd | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 18826491110 |

| Contact: | packson-mould (sale) |

| Last Online: | 08 Nov, 2021 |

Related Products of this Company

-

Silicone Rubber Injection Molding

US $100

-

Silicone Rubber Mold

US $100

-

Plastic Injection Molding

US $100

-

Silicone Rubber Injection Molding

US $100

-

Custom Contract Molding

US $100

-

Medical Silicone Rubber Injection

US $100

-

Explore Packson's Injection Molding

US $100

-

Medical Plastic Injection Molding

US $100