| Model: | GPH846T5L/ |

|---|---|

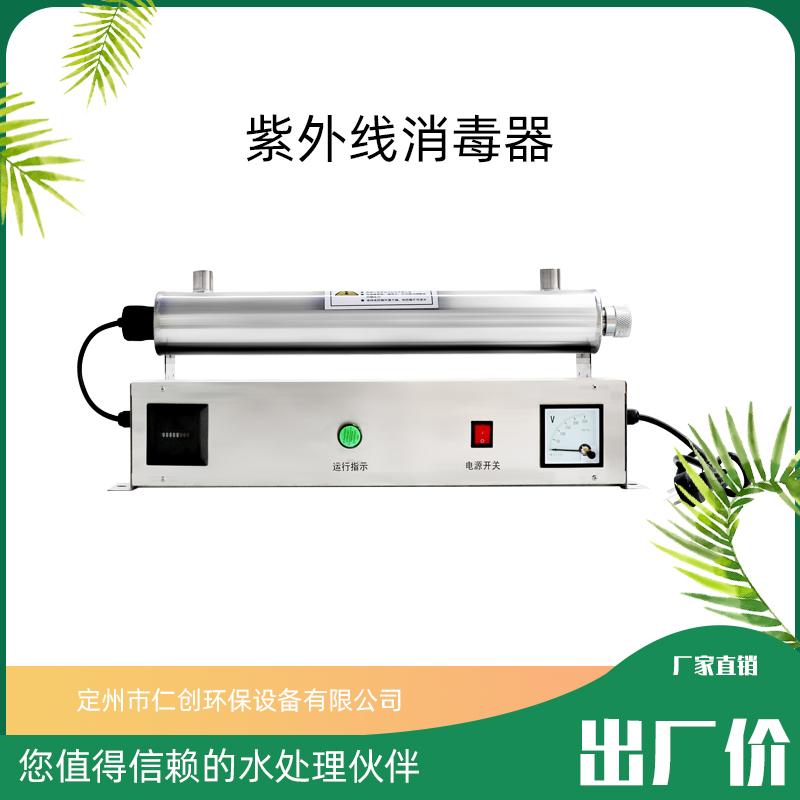

| Brand: | Ren Chuang |

| Origin: | Made In China |

| Category: | Industrial Supplies / Environment Protection Facilities / Sewerage |

| Label: | Ultraviolet lamp , RC series , Ceramic lamp cap |

| Price: |

-

|

| Min. Order: | 1 pc |

Product Description

Gph846t5l / - ultraviolet sterilizer lamp tube can output sufficient UVC intensity. Only artificial mercury (alloy) light source is used for engineering disinfection. The ultraviolet sterilization lamp tube is made of quartz glass. According to the different mercury vapor pressure in the lamp tube and the different ultraviolet output intensity, the mercury lamp is divided into three types: low-pressure low-intensity mercury lamp, medium pressure high-intensity mercury lamp and low-pressure high-intensity mercury lamp. The sterilization effect is determined by the irradiation dose received by microorganisms. At the same time, it is also affected by the output energy of ultraviolet rays, which is related to the type, light intensity and service time of the lamp. With the aging of the lamp, it will lose 30% - 50% of its intensity. Ultraviolet radiation dose refers to the amount of ultraviolet light at a specific wavelength when a certain bacterial inactivation rate is reached: irradiation dose (J / m2) = irradiation time (s) × The greater the irradiation dose of UVC intensity (w / m2), the higher the disinfection efficiency. Due to the size requirements of the equipment, the general irradiation time is only a few seconds. Therefore, the UVC output intensity of the lamp has become the most important parameter to measure the performance of UV disinfection equipment. In urban sewage disinfection, the average irradiation dose is generally more than 300 J / m2. Below this value, light resurrection may occur, that is, the bacteria cannot be completely killed. When they flow out of the channel and receive visible light irradiation, they will resurrect, reducing the sterilization effect. The higher the requirement of sterilization efficiency, the greater the irradiation dose required. The main factor affecting the microorganism to receive sufficient ultraviolet radiation dose is the light transmittance (at 254 nm). When the UVC output intensity and irradiation time are fixed, the change of light transmittance will cause the change of the actual received dose of microorganism.

Gph846t5l / - ultraviolet sterilizer lamp tube most ultraviolet devices use traditional low-voltage ultraviolet lamp technology, and some large water plants use low-voltage high-intensity ultraviolet lamp system and medium voltage high-intensity ultraviolet lamp system. Due to the generation of high-intensity ultraviolet light, the number of lamp tubes may be reduced by more than 90%, thus reducing the floor area and saving installation and maintenance costs, The ultraviolet disinfection method is also applicable to the effluent with poor water quality.

| Payment Terms: | TT |

|---|---|

Member Information

| Dingzhou Renchuang environmental protection equipment Co., Ltd | |

|---|---|

| Country/Region: | He Bei - China |

| Business Nature: | Manufacturer |

| Phone: | 15176399090 |

| Contact: | Zhang (sales manager) |

| Last Online: | 17 Nov, 2021 |