Use of hot rolled pulleys:

Hot-rolled pulley in lifting transportation, port handling, shipbuilding, grab, pulley, mining machinery,

metallurgical machinery, construction It is widely used in installation. It is a new product after casting pulley

and double spoke pulley.

Hot-rolled pulley process:

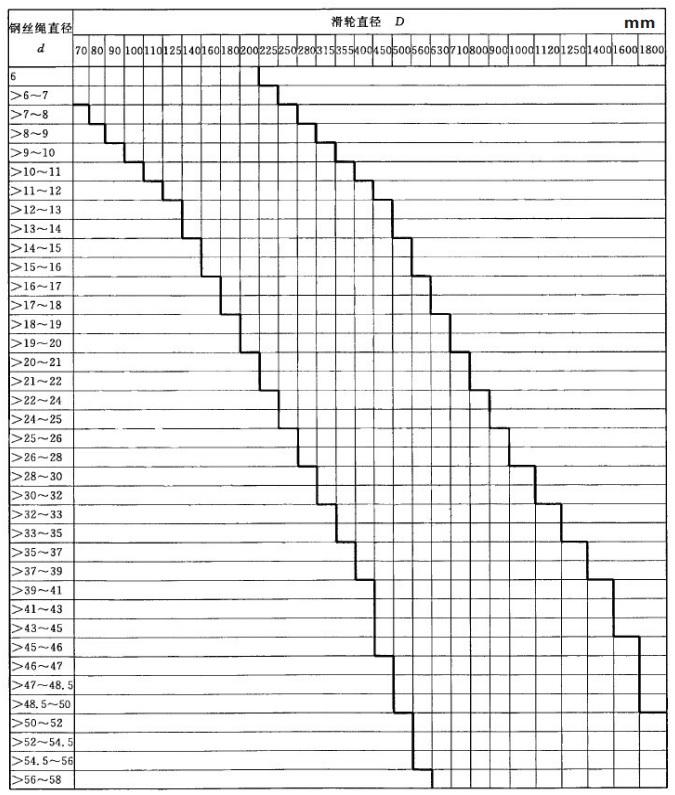

The production of hot rolling pulley is a very professional industry. Our company now has the most superior

hot rolling mill in the same industry. The specifications of180mm-_1800mm are made arbitrarily. Ar+C02 gas shielded

automatic welding is used in all welding, and technicians hold the test. Certification, the main technicalperformance

parameters meet the design requirements. And strictly refer to GB/T 27546-2011 standard implementation, fully able

to To meet the user's requirements. Therefore, it is extremely suitable for the frequent operation of various lifting

machinery. Our company can design students according to customers'requirements Production, fast delivery.

Advantages of hot-rolled pulley:

1. Reasonable structure, high strength and light weight, 40% lighter than casting pulley of the same specification.

2. the groove surface is smooth and wear-resistant, and can be heat-treated to improve its hardness, thereby

prolonging the service life of pulley by 1-2 times.

3. The cutting amount is about 70% less than that of cast pulley, which saves a lot of materials, reduces processing

time and eliminates welding. Posterior deformation.

4. Varieties with different specifications can be produced to suit single-piece or batchproduction.

5. Short manufacturing cycle (10-20 times higher efficiency of hot rolled pulley than cast pulley).

6. High accuracy: 1/1000D radial runout (D-pulley diameter), exceeding 5 specified in the West German standard

DIN15063-77/ 1000D, 2/1000D lateral jump over Japanese standard 3/1000D.

7. Moulding process, beautiful appearance and stable quality.