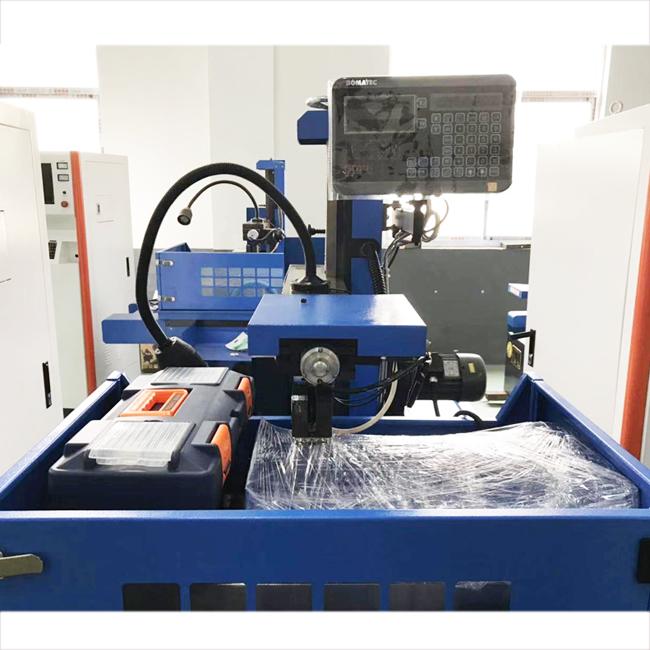

| Model: | DK7750 |

|---|---|

| Brand: | - |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Machine Tool |

| Label: | CNC Cutting Machine , Wedm Wire Cutting , High Speed Wire Cut |

| Price: |

US $7200

/ set

|

| Min. Order: | 1 set |

Product Description

Processing principle of DK7750 electric wire cutting

Electric wire cutting is connected to the negative pole of the pulse power supply through the electrode wire, and the workpiece is connected to the positive pole of the pulse power supply. After the high-frequency pulse power supply is powered on, when the distance between the workpiece and the electrode wire is less than the discharge distance, the pulse electric energy ionizes and breaks down the medium (working fluid) to form a discharge channel. Under the action of electric field force, a large number of negatively charged electrons rush to the positive pole at high speed, The positively charged ions rush to the negative electrode. The high temperature generated by ionization melts or even vaporizes the workpiece surface, so that the metal is thrown out with the movement of the electrode wire and the impact of the working fluid, so as to form pits on the workpiece surface. In the high temperature zone, due to the polarity effect, the energy distributed between the electrode wire and the workpiece is different, so the surface temperature of the electrode wire and the workpiece is also different. Moreover, because the melting temperature of the electrode wire is much higher than that of the workpiece material, and the electrode wire leaves the high temperature zone at high speed, the amount of electrode erosion in the high temperature zone is much less than that of the workpiece, This makes a large pit on the surface of the workpiece and a small pit on the surface of the electrode wire. Because the machining process is continuous, the stepper motor is controlled to feed continuously to maintain the gap necessary to maintain the discharge between the electrode wire and the workpiece, so the workpiece is gradually cut out a gap.

Application scope of DK7750 electric wire cutting

Electric wire cutting is widely used in electronic industry, communication industry, shipbuilding industry, automobile manufacturing industry, weapon industry, aerospace, high-speed railway and other precision molds, EDM electrodes, precision hardware parts and tough and difficult to process conductive materials. It can cut plane, taper and upper and lower special-shaped workpieces, which greatly expands the processing range.

Techical Parameter

|

No. |

Description |

parameter |

|

1 |

project |

High speed wire cutting machine |

|

2 |

Model |

GBDK7750 |

|

3 |

Electrical cabinet form |

Vertical cabinet dqe-ds-03 (full stepper type) |

|

4 |

Guide |

Steel rail |

|

5 |

Lead screw form |

Ball screw |

|

6 |

Xyuv motion motor form |

Reactive stepping motor |

|

7 |

Working mode of wire conveying motor |

Frequency converter speed regulation 1 ~ 12m / S |

|

8 |

Machine tool protection |

Environmental protection cover |

|

9 |

Work table size |

1020X680 |

|

10 |

X. Y axial stroke |

500X630mm |

|

11 |

U. V-axis stroke |

±35×±35mm |

|

12 |

Machining taper / machining thickness |

±6°/80mm |

|

13 |

Maximum straight cutting thickness |

800mm |

|

14 |

control mode |

4 axis linkage |

|

15 |

Maximum load capacity |

800kg |

|

16 |

Maximum processing current |

8A |

|

17 |

Maximum processing efficiency Cr12, H = 60mm |

≥180 mm²/m |

|

18 |

Surface roughness (straight cutting, H≤40mm) |

Ra≤1.6μm |

|

19 |

Cutting accuracy Cr12, H = 40mm |

≤0.015mm |

|

20 |

Radial runout of wire storage cylinder |

≤0.02mm |

|

21 |

Molybdenum wire diameter range |

0.12~0.22mm |

|

22 |

Wire storage capacity of wire storage cylinder |

250m |

|

23 |

Molybdenum wire loss Cr12, H = 40mm |

≤0.02mm /300000mm², |

|

24 |

Cutting power supply |

High frequency power supply system without resistance |

|

25 |

operating system |

Windows 98 / XP (based on control software) |

|

26 |

Control system |

Standard df3a (optional auto / HL / HF, etc.) |

|

27 |

communication interface |

LAN、RS232、USB |

|

28 |

Operation function |

Drawing or CAD drawing import |

|

29 |

Working tank volume |

55L |

|

30 |

Working fluid filtration mode |

Filter screen filtration |

|

31 |

Weight of whole machine |

2500 kg |

|

32 |

Overall dimension of main engine |

2250x1650x1900mm |

|

33 |

Cabinet size |

730×630×1820mm |

|

34 |

Rated power of electric appliance |

≤2.7kW |

Member Information

| Suzhou Talent Import & Export Co., Ltd. | |

|---|---|

| Country/Region: | Jiang Su - China |

| Business Nature: | Trading Company |

| Phone: | 18913180797 |

| Contact: | Flora Wu (assistant) |

| Last Online: | 03 Dec, 2021 |

Related Products of this Company

-

LK-630S Medium speed WEDM machine

US $13000

-

LK-400 Stepper mid-speed WEDM machine

US $10000

-

4HG Turret Milling Machine

US $4500

-

DK7725 wire cut edm machine

US $5500

-

DK7735 wire cutting machine

US $5800

-

DK77120 cnc wire edm machine

US $13000

-

DK7745 CNC wire cut edm

US $6000

-

LK-500S Medium speed WEDM machine

US $12000

-

LK-800S Medium speed WEDM machine

US $14000

-

LK-630 Stepper mid-speed WEDM machine

US $13000