| Model: | HT003 |

|---|---|

| Brand: | Huatao |

| Origin: | Made In China |

| Category: | Textile & Leather / Fabrics / Other Fabrics |

| Label: | dryer screen , dryer fabric , dryer canvas |

| Price: |

US $800

/ Unit

|

| Min. Order: | 1 Unit |

Product Description

Huatao Group - Paper Machine And Fabrics

www(dot)papermachineclothings(dot)com

Email: sandy@huataogroup.com sandy(at)huataogroup(dot)com

Tel: 0086 0311 80690567

Mob: 0086 133 8311 0583

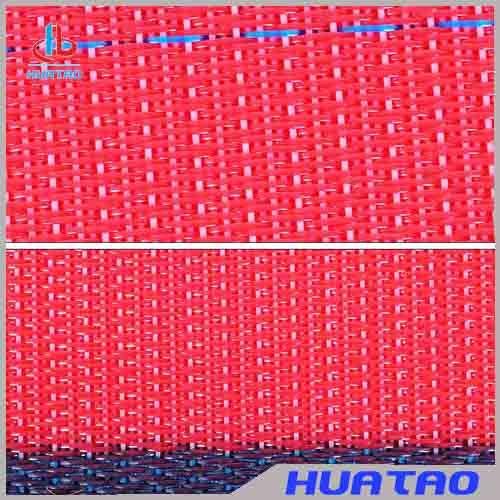

Dryer screen can be classified depending on weaving struction can be devided into WOVEN type and SPIRAL type.

Huatao has developed a wide range of spiral dryer screen to meet each client's needs helping to reduce operation cost through energy efficient solutions. Also called as Spiral link dryer fabric or SLDF, spiral dryer screen is assembled with spiral loops linked by a pin yarn inserted in the adjacent holes. Spiral fabrics are widely used in various industries as paper machine dryer screen, drying & conveyor belts, filter cloth or screening media. Excellent materials are adopted to make the spiral fabric to protect against hydrolysis and high temperatures conditions. Depending on the filler wire added to the spiral dryer screen, air permeability range from 100 to 1380 CFM.

The selection of dryer screen is depending on the various paper machine parameters such as paper grades, dryer cylinders configuration, dryer cylinder temperatures, air balance in the hood etc. Dryer screen design and materials are also very important.

For a particular paper machine, the permeability, design and materials of the dryer screen should be adapted to make sure optimum drying from a drying section. The air permeability of the dryer screen has a great impact on the rate of evaporation of water. If the permeability is decreased, then it is reduction in drying capacity of the dryer screen.

The dryer screen, whose air permeability range between 700-1000cfm is used on paper machine for producing higher gsm Kraft and board varieties. On the other hand 200-400cfm dryer screen widely used in medium and high speed paper machine and below these rage used in lower speed paper machine. High numbers of contact areas with the drying surface ensure uniform drying.

Proper chosen of dryer clothing improve paper machine runnability, increased drying rate, improved paper quality and savings energy.

Flat yarn spiral dryer screen composed of flat wire, the surface dryer screen is smoothly, depending on the filling yarn added to the spiral dryer screen, air permeability range from 100 to 1380 CFM.

With its flexible and adjustable permeability and perfect surface, the paper breaking caused by airflow disturbance is greatly reduced, thus improving the production efficiency of paper machine, the flat yarn spiral dryer screen mainly used to the high speed paper machine which required high grade of paper.

The selection of dryer screen is depending on the various paper machine parameters such as paper grades, dryer cylinders configuration, dryer cylinder temperatures, air balance in the hood etc. Dryer screen design and materials are also very important.

For a particular paper machine, the permeability, design and materials of the dryer screen should be adapted to make sure optimum drying from a drying section. The air permeability of the dryer screen has a great impact on the rate of evaporation of water. If the permeability is decreased, then it is reduction in drying capacity of the dryer screen.

The dryer screen, whose air permeability range between 700-1000cfm is used on paper machine for producing higher gsm Kraft and board varieties. On the other hand 100-400cfm dryer screen widely used in medium and high speed paper machine, high numbers of contact areas with the drying surface ensure uniform drying.

Proper chosen of dryer clothing improve paper machine runnability, increased drying rate, improved paper quality and savings energy.

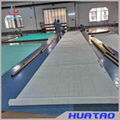

We has launched new flat yarn woven dryer screen, which is a unique two-tier flat warp weave screen with controlled permeability, recommended for Unirun positions and high speed machines. The higher surface contact area helps to increase the heat transfer with better sheet support thus lowering the energy consumption.

PPS yarn have better wear resistance and high temperature resistance than PET yarn, with Huatao's special design add the PPS yarn into the edge of dryer screen ensure higher life.

The selection of dryer screen is depending on the various paper machine parameters such as paper grades, dryer cylinders configuration, dryer cylinder temperatures, air balance in the hood etc. Dryer screen design and materials are also very important.

For a particular paper machine, the permeability, design and materials of the dryer screen should be adapted to make sure optimum drying from a drying section. The air permeability of the dryer screen has a great impact on the rate of evaporation of water. If the permeability is decreased, then it is reduction in drying capacity of the dryer screen.

The dryer screen, whose air permeability range between 700-1000cfm is used on paper machine for producing higher gsm Kraft and board varieties. On the other hand 200-400cfm dryer screen widely used in medium and high speed paper machine and below these rage used in lower speed paper machine. Proper chosen of dryer clothing improve paper machine runnability, increased drying rate, improved paper quality and savings energy.

Member Information

| Shijiazhuang Huatao Import And Export Trade Co.,Ltd | |

|---|---|

| Country/Region: | He Bei - China |

| Business Nature: | Manufacturer |

| Phone: | 13383110583 |

| Contact: | Sandy Qin (Sales) |

| Last Online: | 07 Jun, 2022 |

Related Products of this Company

-

Paper Making Felt, Pick Up felt, Seamed

US $800

-

Forming fabric, SSB Forming Wire

US $1000

-

Paper Machine Clothings

US $1000