| Model: | - |

|---|---|

| Brand: | - |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Heat Exchange & Air Conditioners |

| Label: | finned tube , fin tube , heat exchanger |

| Price: |

US $50

/ pc

|

| Min. Order: | 100 pc |

Product Description

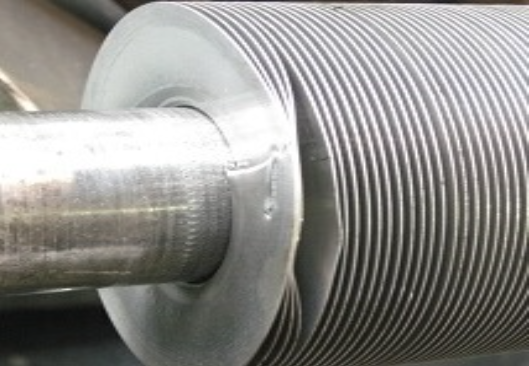

KL Fin Tubes also called knurled finned tubes. This finned tube is basically identical to the Wrap-On fin and produced with a combination of Wrap-On and Embedded. The fins are manufactured from strip which is preformed into an accurately controlled L shape similar to the L type, rolled into a taper which causes it to curl. It is then continuously helically wound under tension onto the tube. The fin wrapped around the tube. The base tube is knurled by a rotating tool, then the foot of the fin is knurled into the knurling of the base tube providing a tight bond with increased thermal performance. Providing the correct fin strip is used the foot of one fin butts up against the next fin and there is no gap between the fins. This gives some corrosion protection to the tube. The fins are secured at each end to prevent unwinding in a similar way as L fins.

The fin is wrapped around the tube and the foot is rolled into the outer surface of the pre knurled tube and secured at each end. Gives good surface protection to the tube and improved heat transfer compared to the L or LL type fin. KL -Foot tension wound finned tubes are commonly used in applications with metal Maximum Operating Temperature- up to 320°C (608°F)

Advantages of the KL Fin Tubing

Tube protected against corrosion

Medium temperature applications

Increased fin to tube bond

Greater thermal contact than standard L fin

Added heat transfer performance due to the knurling

Increased atmospheric corrosion protection of the core tube

Good stability

Resistant to vibrations

May be used at temperature up to 320°C (608°F)

Unique combination of high thermal performance and stresses resistance with atmospheric corrosion protection

KL can favorably replace any type of finned tubes.

Manufactured method is exactly as the L finned tube except that the base tubes are knurled before application of these fin foot. After application, the fin foot is knurled into the corresponding knurling on the base tube thereby enhancing the bond between the fin and tube, resulting in improved heat transfer characteristics.

Base Tube materials: Any material available, such as Carbon Steel/ Carbon Alloy Steel/Stainless Steel/ Nickel Alloys/ Copper/Copper Alloys/Titanium, A179, A192, A210, stainless tube A269/A213 T5 T11 T22 304 316

Tube Diameter:1/2” (12.7mm) to 2” (50.8mm)

Tube Wall Thickness:> 0.049” (1.244mm) depending on tube material and outside diameter

Fin Heights:1/4” (6.35mm) to 1” (25.4mm)

Fin Pitches:5 to 12 fins per inch

Fin Strip Thickness:0.012” (0.30mm) to 0.020” (0.50mm)

The fin is wrapped around the tube and the foot is rolled into the outer surface of the pre knurled tube and secured at each end. Gives good surface protection to the tube and improved heat transfer compared to the L or LL type fin. This finned tube is used for moderate temperature cooling applications.

Upper Temperature limit: 250°C

Tube Material: Any standard material we stock or is requested

Fin Material: Aluminium or Copper

In order to forward you a promt offer we would be pleased to receive you detailed enquiry including:

• Base tube material

• Base tube size (OD x WT x Length)

• Fin material

• Fin type

• Fin diameter or height

• Fin thickness

• Fins per inch, meter or fin pitch

• Lenght of plain, unfinned ends

• Finned Tube Quantity

(Additional fabrication, such as bend or weld the tubes into tubeplate or assembly)

| Payment Terms: | TT/LC/DP/DA |

|---|---|

Member Information

| Shanghai T.S. Industrial Co.,Ltd | |

|---|---|

| Country/Region: | Shang Hai - China |

| Business Nature: | Manufacturer |

| Phone: | 15607960723 |

| Contact: | Estela (clerk) |

| Last Online: | 18 Aug, 2022 |

Related Products of this Company

-

M Type Fin Tube Medium Finned Tube

US $50

-

Spiral Wound Finned Tube Galvanized

US $50

-

Double S Type Fin Tube Rectangular

US $50

-

Integral Low Finned Tube Integral Low

US $50

-

HYS Type Fin Tube Extruded Serrated

US $50

-

180° elbow U bend elbow Short radius

US $5

-

LFW Type Fin Tube Longitudinal Finned

US $50

-

Studded Tubes

US $50

-

Elliptical Tube With Rectangular Fins

US $50

-

HY Type Fin Tube Extruded Finned Tube

US $50